Device and method for converting thermal energy

A heat energy and heat energy conversion technology, used in refrigeration and liquefaction, lighting and heating equipment, independent rotary compressors, etc., can solve the problem that the equipment cannot be the minimum length, and achieve the effect of high stability, space saving and size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

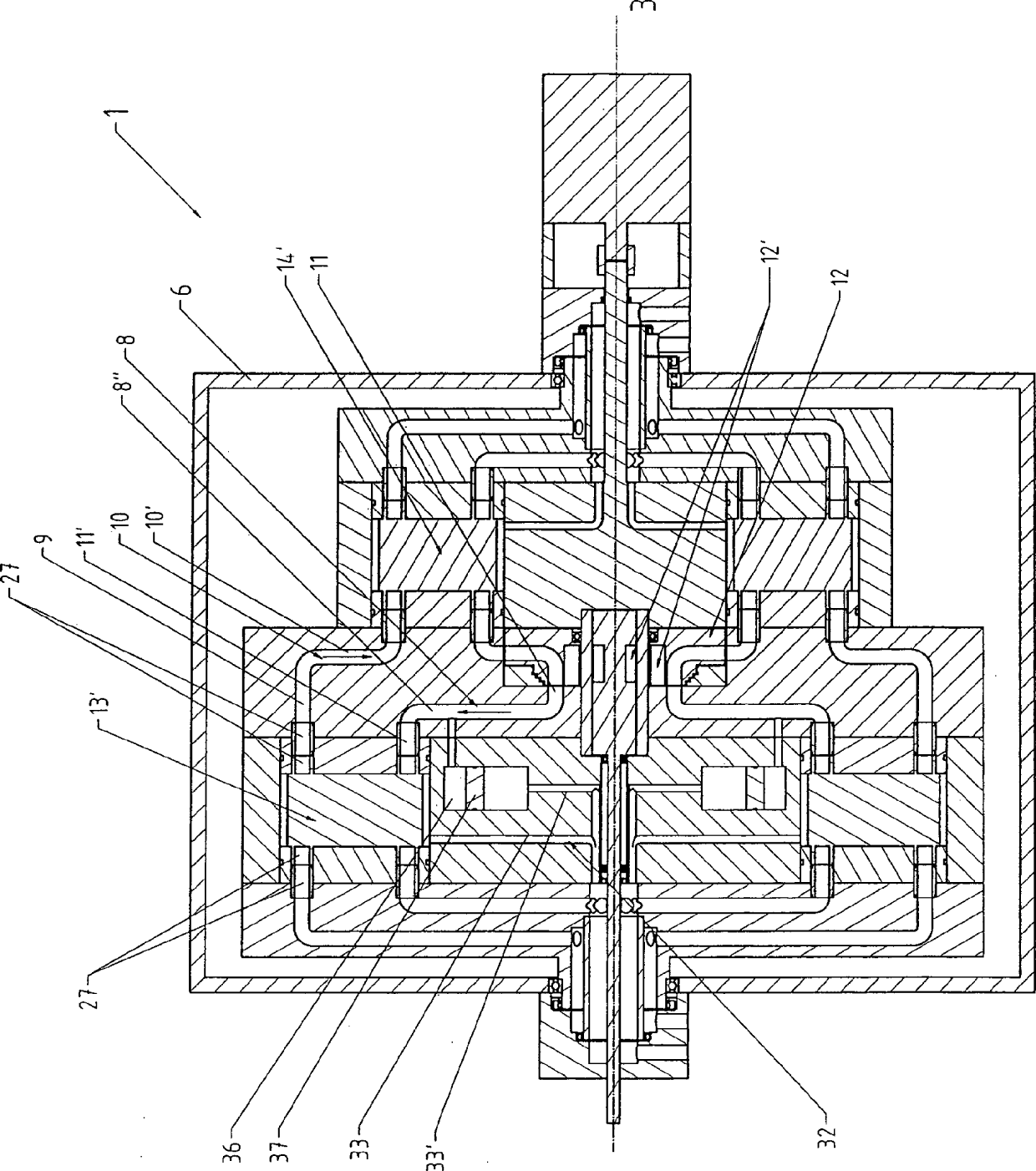

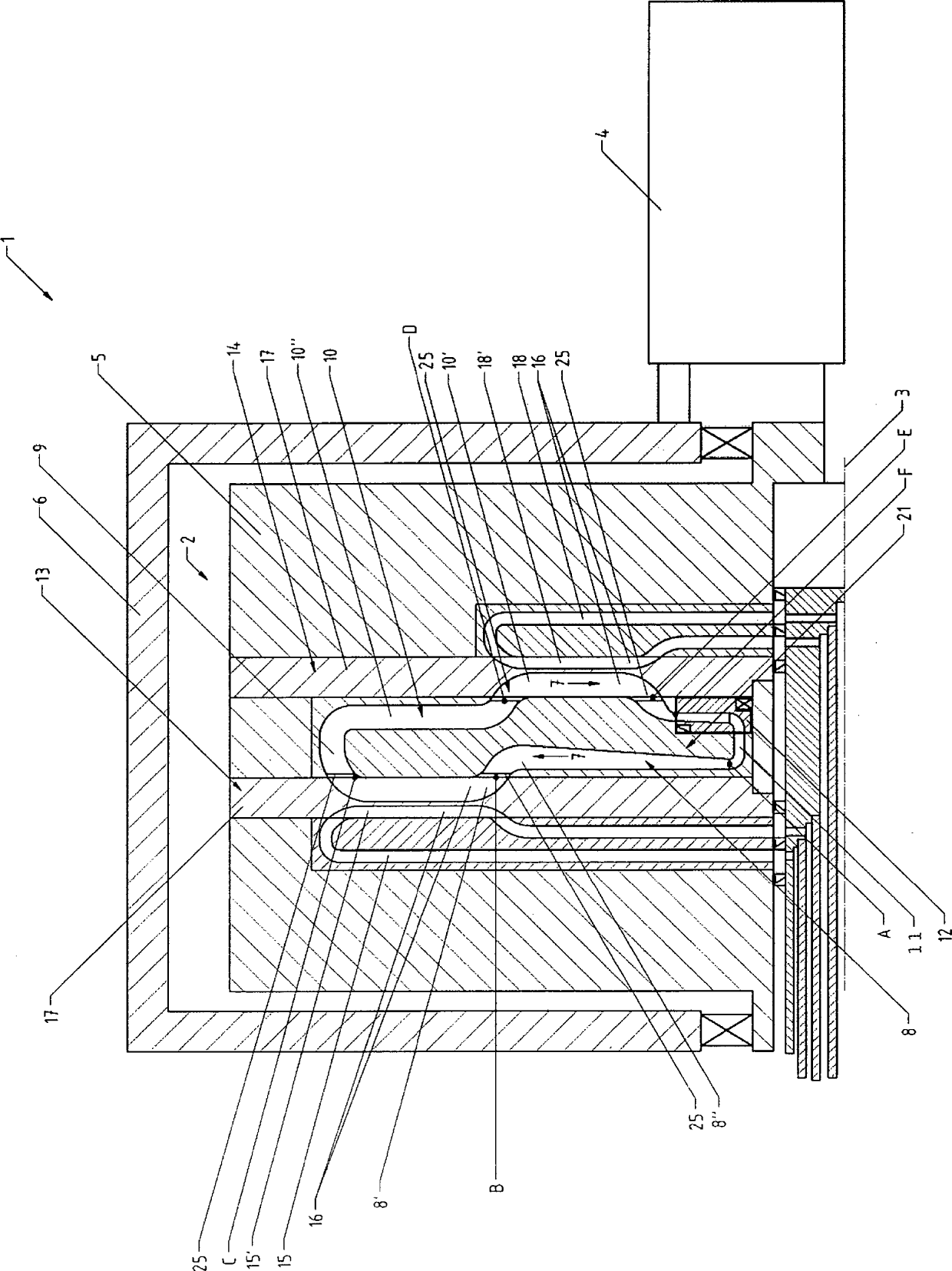

[0057] FIG. 1 shows a device 1 according to the invention for converting mechanical energy into thermal energy and vice versa, which is operated as a heat pump in the illustrated exemplary embodiment. The device 1 comprises a rotor 2 driven by a rotating shaft 3 of a motor 4 . The rotor 2 has a block-shaped rim 5 which is accommodated in an outer, stationary housing 6 . Closed flow channels for the working medium carrying out the circulating process, which is present in a gaseous state during the entire cycle, are formed in the rotor 2 . The working medium, eg argon, is guided clockwise or in the direction of the arrow 7 from the compression channel 8 via the first connecting channel 9 into the pressure-relief channel 10 , which is connected to the compression channel 8 via the second connecting section 11 middle. The compression channel 8 and the pressure relief channel 10 are respectively arranged approximately perpendicular to the axis of rotation 3 , while the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com