Novel hand-pressing type multipurpose rotary mop rod

A rotary mop and hand-pressed technology, which is applied in the field of hand-pressed multi-purpose rotary mop rods, can solve the problems of reduced service life, high production cost, and easy damage to the bottom of the bucket, and achieve low manufacturing cost, small resistance, and labor-saving use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

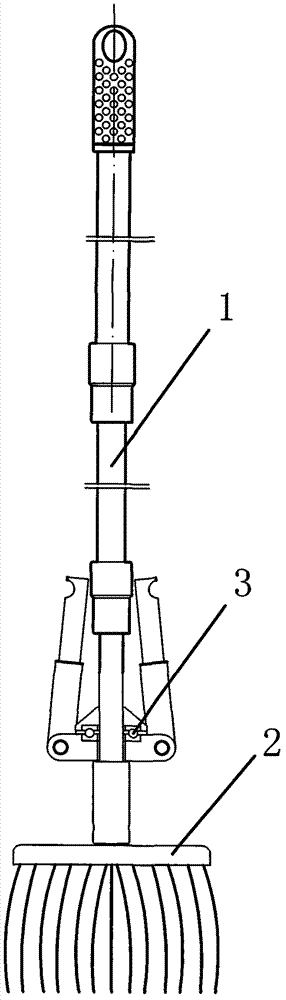

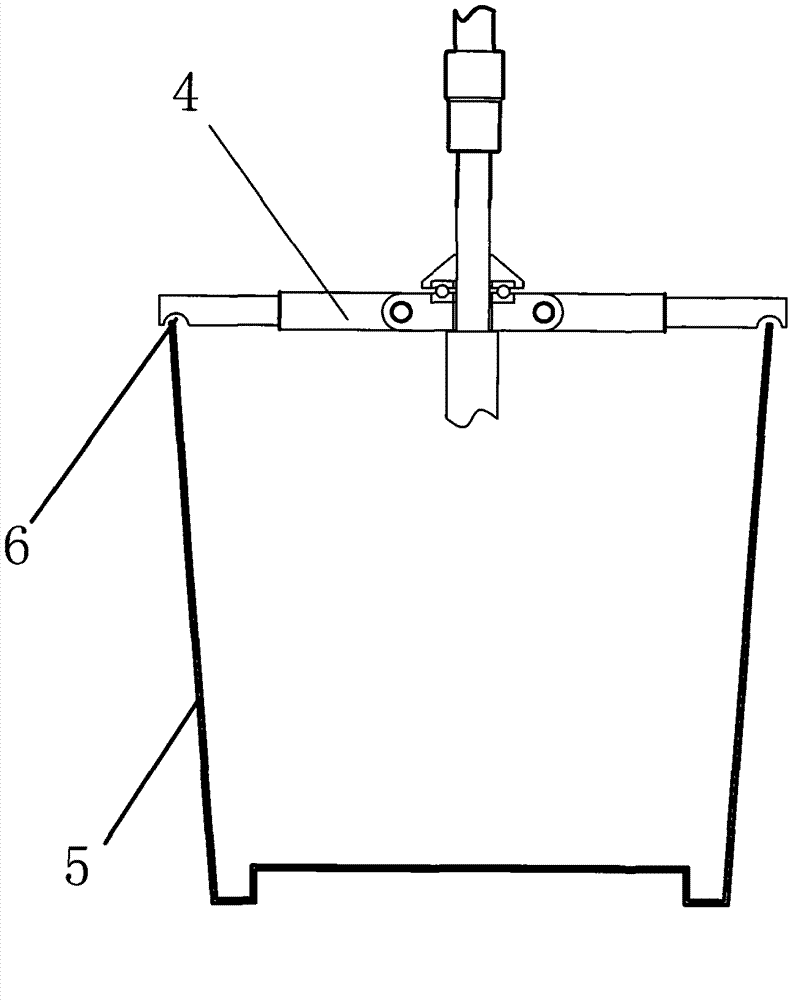

[0013] Such as figure 1 , 2 As shown, a novel hand-pressed multi-purpose rotary mop bar includes a tow bar 1 and a tow head 2. The tow bar is covered with a swivel seat 3 that can rotate relative to the tow bar; The side hinge is installed with the support bar 4 that can be closed along the bar when not in use supported on the staving 5, and the support bar rests on the upper edge of the staving. The support rod is composed of an inner rod and an outer rod telescopically socketed, and the outer rod is provided with a positioning groove 6 for the upper edge of the barrel to be embedded. The tow bar is composed of an upper bar and a lower bar socket, and the swivel seat is installed on the lower bar. Alternatively, the support rod is composed of an inner rod and an outer rod telescopically socketed, and the inner rod is provided with a positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com