Carbon black coating device for cables

A coating device and carbon black technology, which is applied to the surface coating liquid device, coating, cable/conductor manufacturing, etc., can solve the problems of carbon black easily scattered on the ground, uneven coating, slippery ground, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

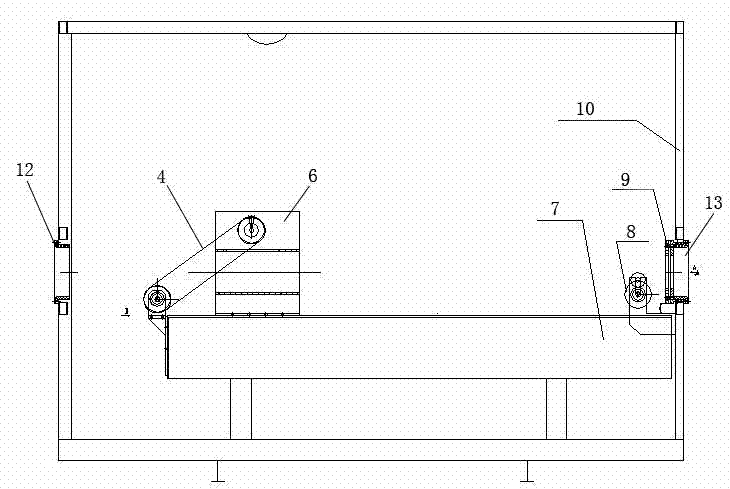

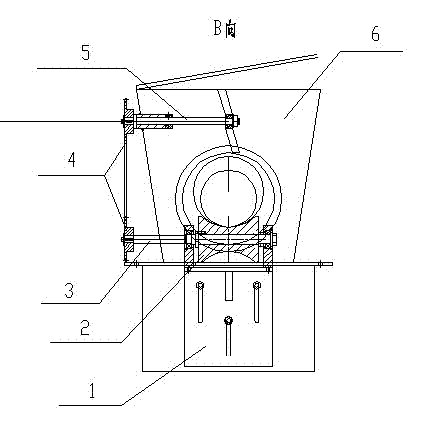

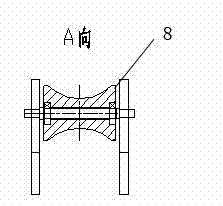

[0016] The structure and working method of this device are further described below in conjunction with the accompanying drawings:

[0017] This device includes the following structural components:

[0018] Supporting roller frame 1: installed on the front end of the carbon black recovery tank 7, it is used to support the active supporting roller 2, and the up and down height of the support can be adjusted according to the diameter of the cable.

[0019] Active supporting wheel 2: installed on the upper end of the supporting wheel frame 1 through the supporting wheel shaft 3, the self-weight of the cable drives the supporting wheel to drive the sprocket drive.

[0020] Supporting wheel shaft 3: Connect the driving supporting wheel 2 to rotate together with the sprocket.

[0021] Sprocket and chain 4: connect one end of the supporting wheel shaft 3 with the outer end of the stirring shaft, and play a transmission role.

[0022] Stirring shaft and impeller 5: One end of the sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com