High-precision extrusion forming machine

A molding machine and high-precision technology, applied in the field of high-precision extrusion molding machines, can solve the problems of low material utilization rate, easy deformation, and large material waste, achieving high material utilization rate, ensuring processing accuracy, and not easy to deform Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

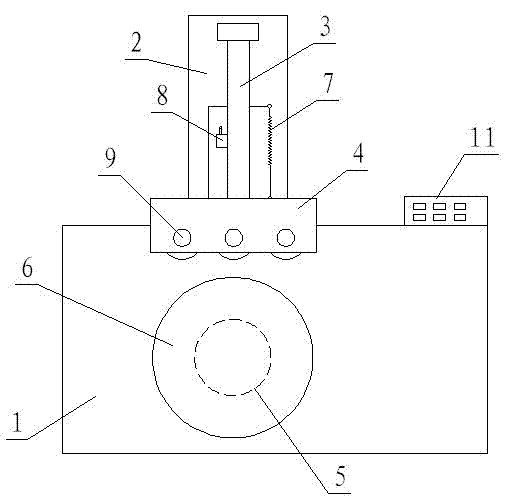

[0010] See figure 1 As shown, a high-precision extrusion molding machine of the present invention includes a workbench 1, a hydraulic cylinder fixing frame 2 arranged on the workbench 1, and a hydraulic cylinder 3 fastened to the hydraulic cylinder fixing frame 2, so The bottom end of the hydraulic cylinder 3 is connected with a hydraulic push combination press wheel 4, the workbench 1 is provided with a motor 5, the workbench 1 is provided with a forming mold 6 driven to rotate by the motor 5, and the hydraulic cylinder fixing frame 2 It is equipped with a hydraulic lifting spring 7 and a hydraulic cylinder stroke limit switch 8. When working, the strip steel plate is bent and pressed against the forming mold under the action of the hydraulic pushing combination pressure wheel; through the hydraulic pressure Push the combination pressure roller 4 to lift the spring 7 and the hydraulic cylinder 3 stroke limit switch, hydraulically push the combination pressure wheel 4 to lift t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com