Mechanical automatic feeding and discharging device

An automatic loading and unloading, mechanical technology, applied in metal processing and other directions, can solve the problems of wasting manpower, the safety of staff cannot be effectively guaranteed, and the work efficiency is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

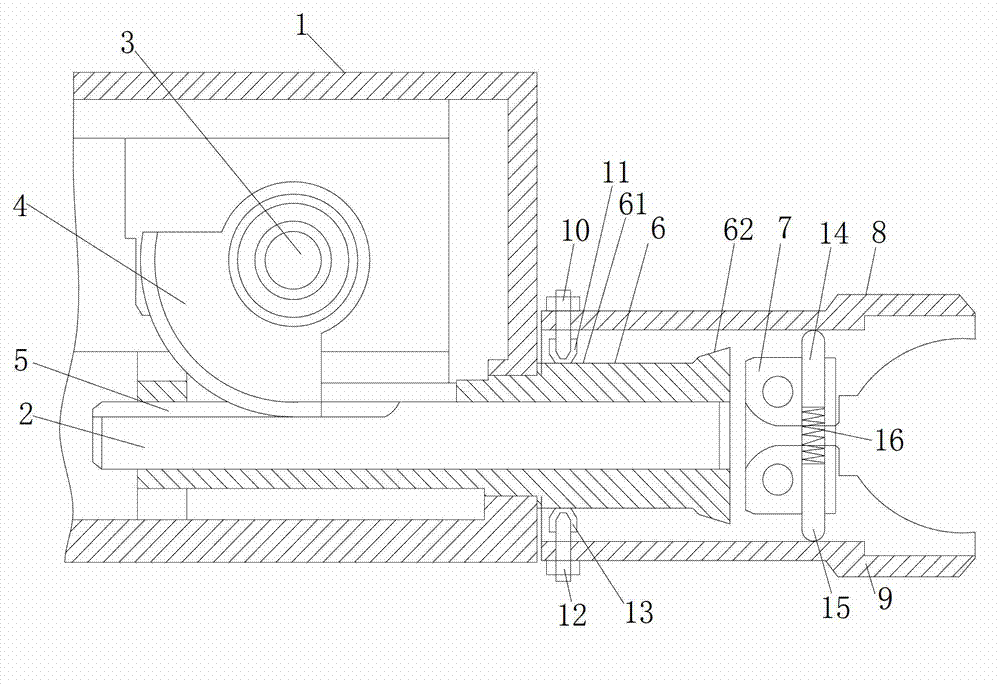

[0014] see figure 1 , a mechanical automatic loading and unloading device, the device includes a base 1, a transmission shaft 2, one end of the transmission shaft 2 extends into the base, the other end extends outside the base, and the transmission shaft is set on the base to drive the shaft back and forth A driving mechanism for movement, the driving mechanism includes a driving shaft 3 arranged on the base 1, a driving gear 4 fixedly arranged at one end of the driving shaft 3, and a tooth groove 5 matched with the driving gear 4 is arranged on the transmission shaft 2;

[0015] A guide sleeve 6 for guiding the transmission shaft 2 is fixedly arranged on the base 1. The outer diameter of one end 61 of the guide sleeve 6 is smaller than the outer diameter of the other end 62. The end of the transmission shaft 2 exposed from the base passes thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com