Converter gas and pulverized coal mixed combustion device

A technology for mixing converter gas and pulverized coal, which is applied to burners, rotary drum furnaces, furnaces, etc., can solve the problems that the calcination temperature cannot meet the needs of lime production, the product quality cannot be guaranteed, and the complete combustion cannot be achieved. Achieve the effect of reducing the temperature at the end of the rotary kiln, ensuring the safety factor, and improving the full utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

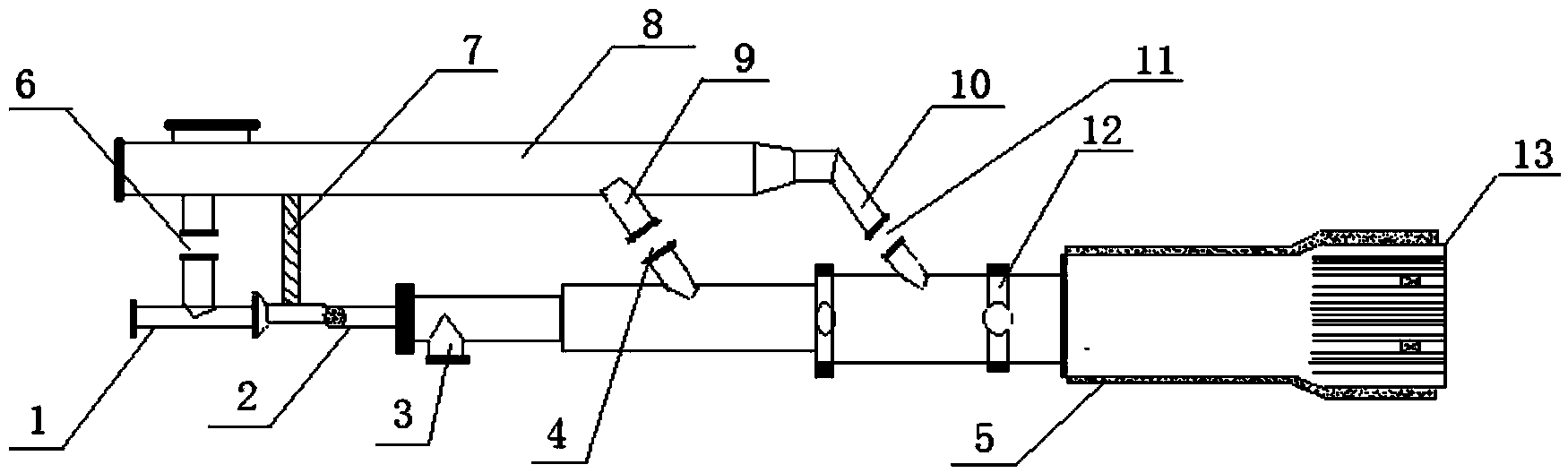

[0019] Such as figure 1 As shown, a converter gas and pulverized coal mixed combustion device includes a main air duct 8, a nozzle 13, a support rod 7, a protective layer 5 and a channel structure, the protective layer 5 is arranged on the outer layer of the nozzle 13, and the support rod 7 guides the main The air channel 8 is stable, and the channel structure and the nozzle 13 are connected by the connecting piece 12, which ensures that the burning lime of the lime rotary kiln can be realized; the channel structure is composed of a central air channel 1, a pulverized coal channel 2, and a converter gas inlet 3 , the swirl air duct 9 and the axial flow air duct 10; one end of the axial flow air duct 10 is connected with the end of the main air duct 8, and the other end is connected with the channel structure near the nozzle 13; the pulverized coal channel 2 is arranged in the central wind between the channel 1 and the converter gas inlet 3; the central air channel 1 is set at ...

Embodiment 2

[0021] According to the converter gas and pulverized coal mixed combustion device described in Embodiment 1, the butterfly valve is divided into butterfly valve a6, butterfly valve b4, and butterfly valve c11. Butterfly valve a6 is set on the central air duct 1, butterfly valve b4 is set on the swirl air duct 9, and butterfly valve c11 It is arranged on the axial flow air duct 10; furthermore, the ventilation volume in the channel structure can be adjusted, so that the fuel transportation speed and combustion speed are increased, thereby increasing the calorific value and improving product quality.

Embodiment 3

[0023] According to Embodiment 1 or Embodiment 2, the protective layer 5 is a refractory cast layer, which further prolongs the service life of the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com