Graphite-organic compound combined artware production system

A technology for organic compounds and production systems, applied in presses, manufacturing tools, presses for material molding, etc., can solve problems such as affecting the accuracy of raw material mixing ratio, waste of excess raw materials, etc., to extend apparent life and improve packaging. The effect of covering the effect and improving the full utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

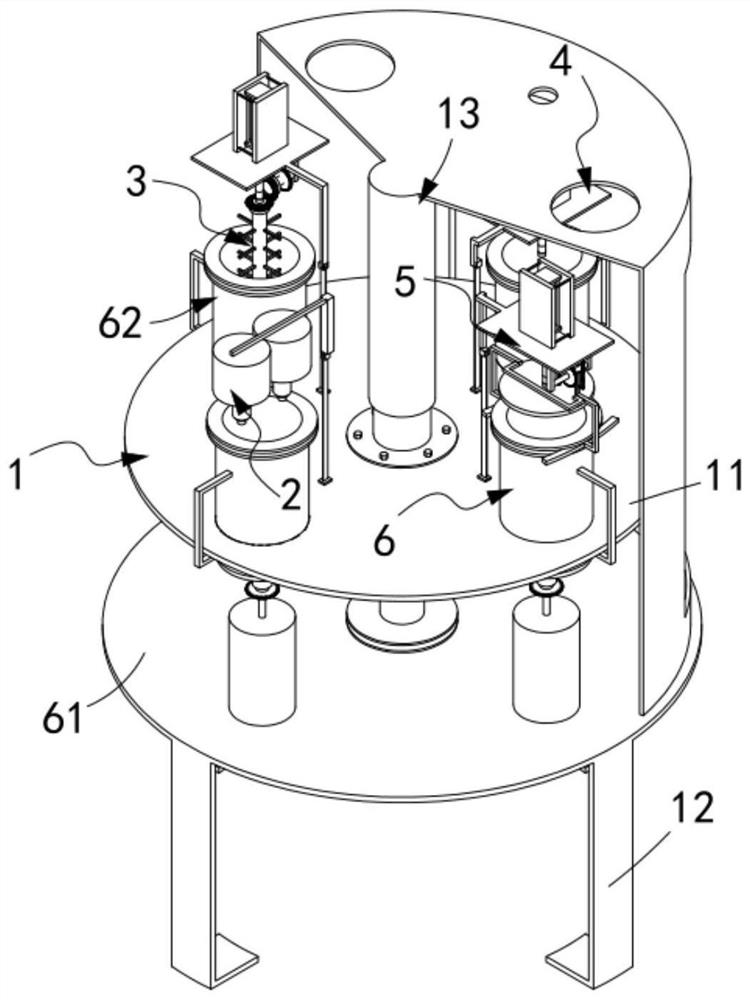

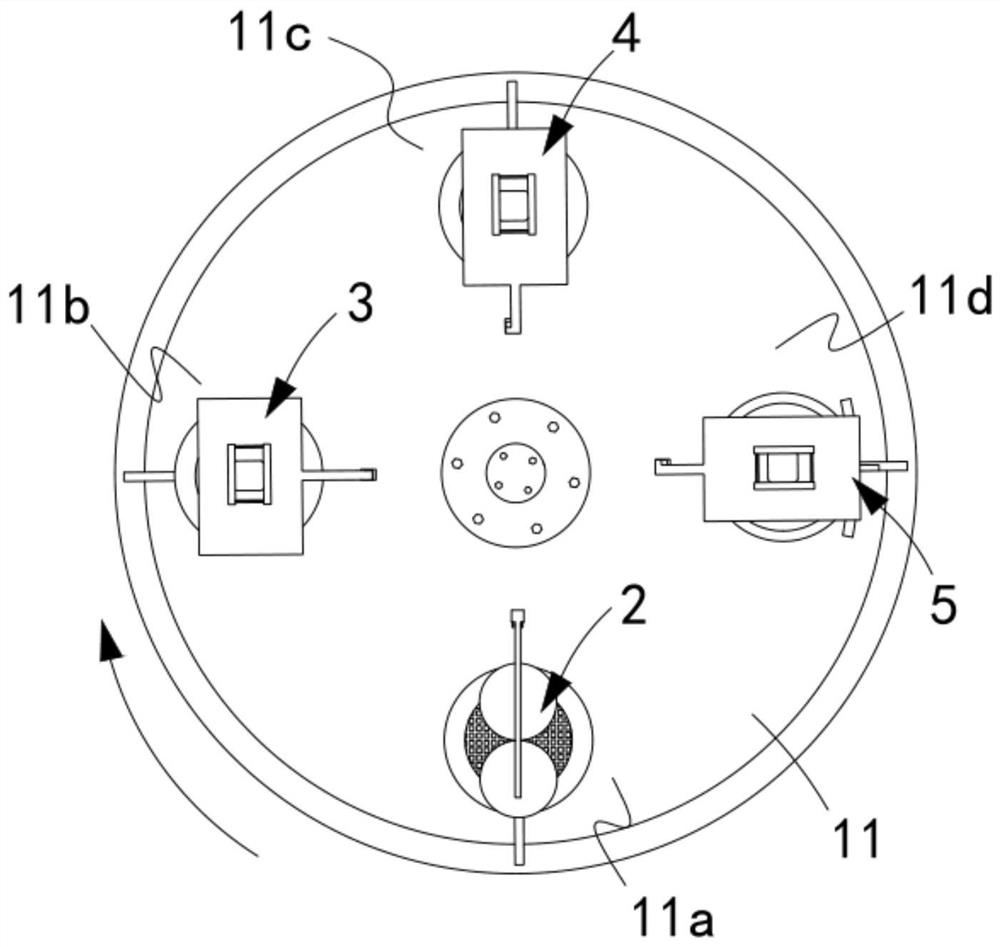

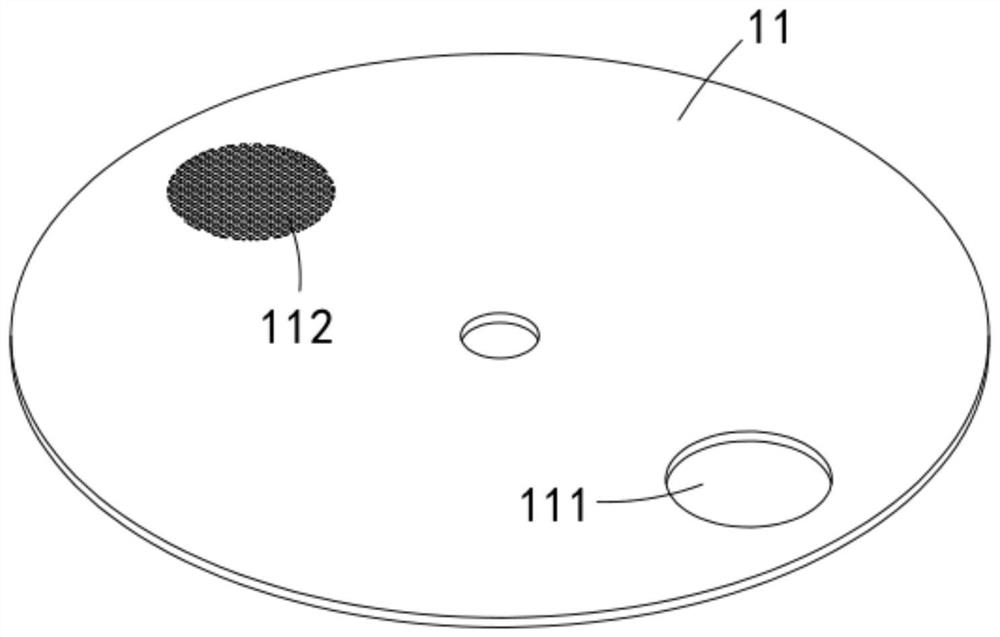

[0053] Such as figure 1 , Figure 4 with Figure 5 Shown, a kind of handicraft production system that graphite-organic compound combines, comprises:

[0054] A driving mechanism 1, the driving mechanism 1 includes a rotating disk 11 and a driving member 13 installed on the frame 12 and used to drive the rotating disk 11 to rotate in a circle, and the rotating disk 11 is sequentially provided with feeding materials along the circumferential direction Station 11a, mixing station 11b, primary static pressure station 11c and cladding station 11d;

[0055] A feeding mechanism 2, the feeding mechanism 2 is installed on the rotating disk 11 and is located directly above the feeding station 11a;

[0056] A stirring mechanism 3, the stirring mechanism 3 is installed on the rotating disk 11 and is located directly above the mixing station 11b;

[0057] A static pressure mechanism 4, the static pressure mechanism 4 is installed on the rotating disk 11 and is located directly above th...

Embodiment 2

[0087] Such as Figure 11 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0088] further, such as Figure 11As shown, the lower end of the receiving container 623 is an open-cover structure;

[0089] The bottom cover of the receiving dish 623 is provided with an outlet 626, a ring rack 627 is fixedly arranged between the mixing station 11b and the primary static pressure station 11c, and an on-off valve 628 is arranged on the outlet 626 , the switch valve 628 is provided with a transmission gear 629 for driving the switch valve 628 to switch, and the transmission gear 629 is engaged with the ring rack 627;

[0090] The c material feeding bin 620 is communicated with the outlet 626 .

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com