A processing device for preparing p-toluenesulfonyl chloride

A technology of p-toluenesulfonyl chloride and processing equipment, which is applied in the field of organic grease, can solve the problems of impurities, difficult control of reaction temperature, and slow temperature drop in reaction space, etc., and achieve high degree of automation, increase full utilization rate, and increase dissolution depth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

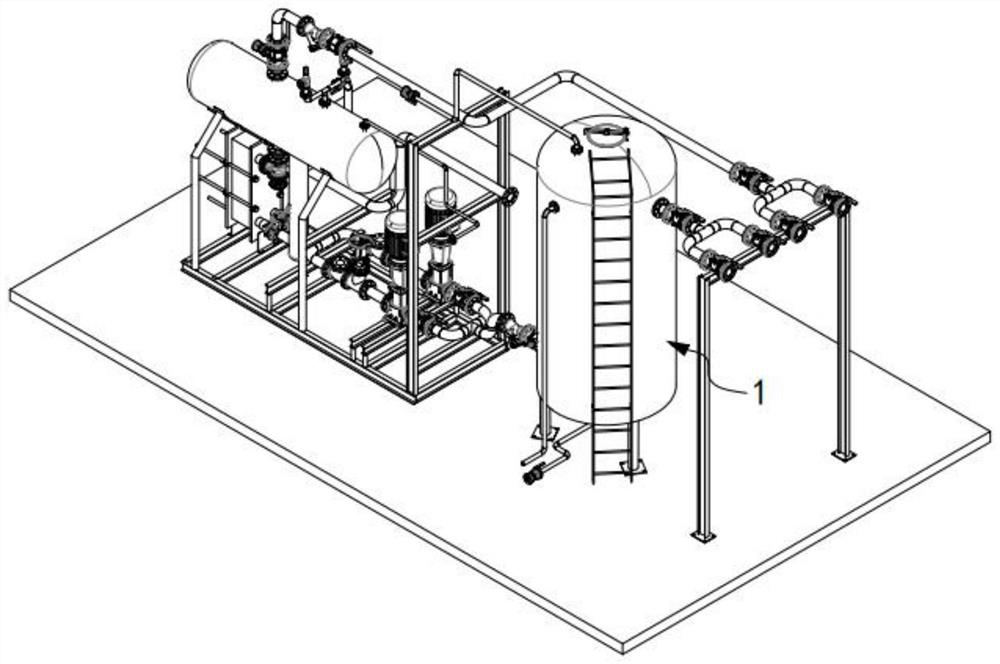

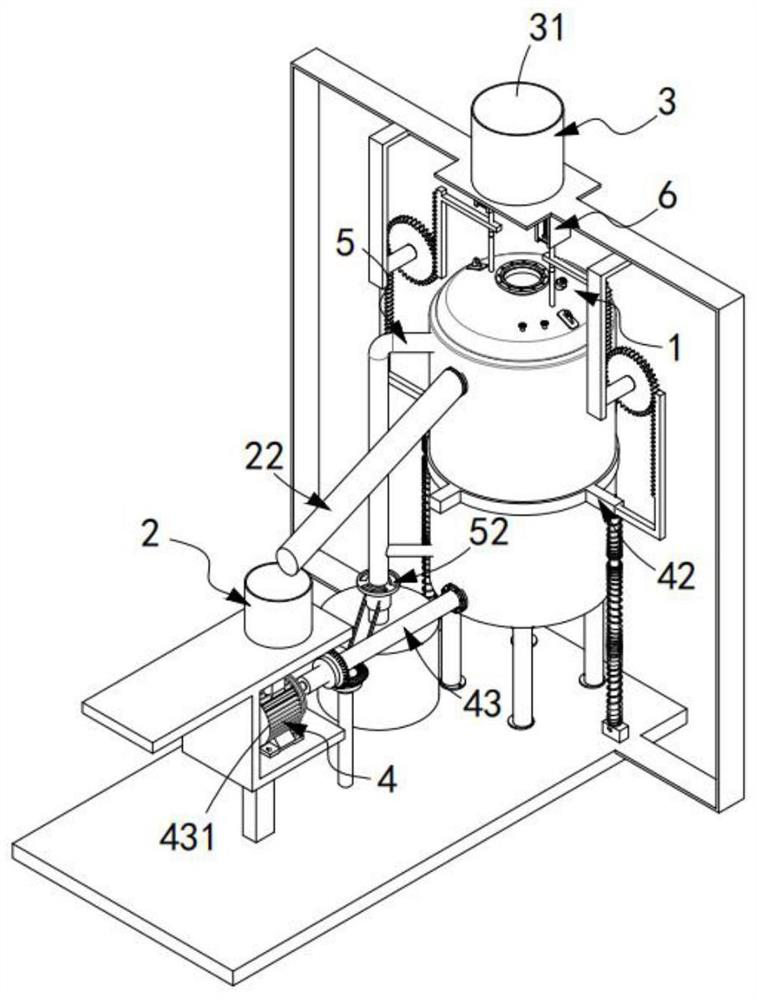

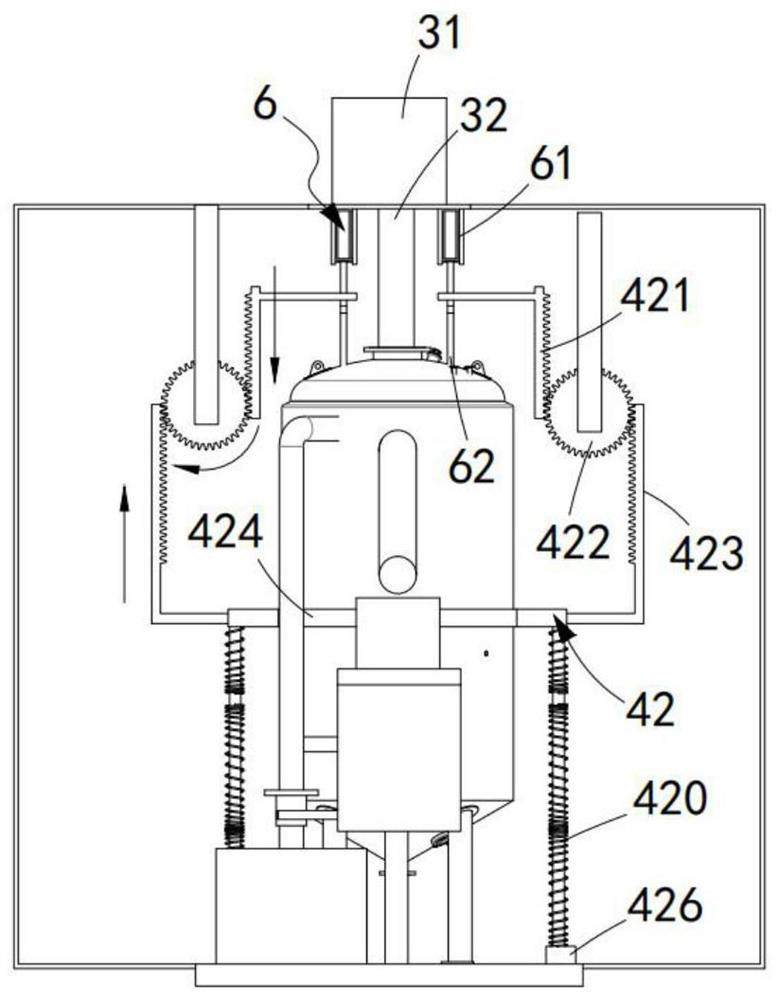

[0070] Such as Figure 1 to Figure 5 As shown, a processing device for preparing p-toluenesulfonyl chloride includes a reactor 1, and also includes a cleaning mechanism 2, a uniform drip mechanism 3, a stirring mechanism 4, and is arranged outside the reactor 1 and connected to the reactor 1 connected gasoline transmission mechanism 5;

[0071] The cleaning mechanism 2 includes a cleaning assembly 21 arranged at the upper end of the reaction kettle 1 and above the stirring mechanism 4 and a collection assembly 22 arranged outside the reaction kettle 1;

[0072] The uniform drip mechanism 3 includes a water container 31 arranged outside the reaction kettle 1, a first connecting pipe 32 that is connected to the water container 31 at one end and sealed with the inside of the reaction kettle 1 at the other end, and is arranged on the inside of the reaction kettle 1. The control assembly 33 in the reaction kettle 1 and communicated with the first connecting pipe 32 and the pressur...

Embodiment 2

[0122] Such as figure 2 , Figure 4 , Figure 19 to Figure 21 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0123] further, such as Figure 19 to Figure 21 As shown, the cleaning assembly 21 includes:

[0124] A second connecting pipe 211, the second connecting pipe 211 is arranged in the reaction kettle 1;

[0125] A spray arc plate 212, the spray arc plate 212 is arranged in communication with the second connecting pipe 211 and both ends are fixedly arranged on the inner wall of the reaction kettle 1; and

[0126] The limit arc plate 213, the limit arc plate 213 is arranged in close contact with the lower surface of the spray arc plate 212 and is arranged on the reaction kettle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com