Betel nut slicing machine

A slicer and betel nut technology, applied in metal processing, etc., can solve the problems of rough cutting surface, potential safety hazards, low cutting production efficiency, etc., and achieve the effect of reasonable structural design, high degree of automation, and smooth cutting surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing:

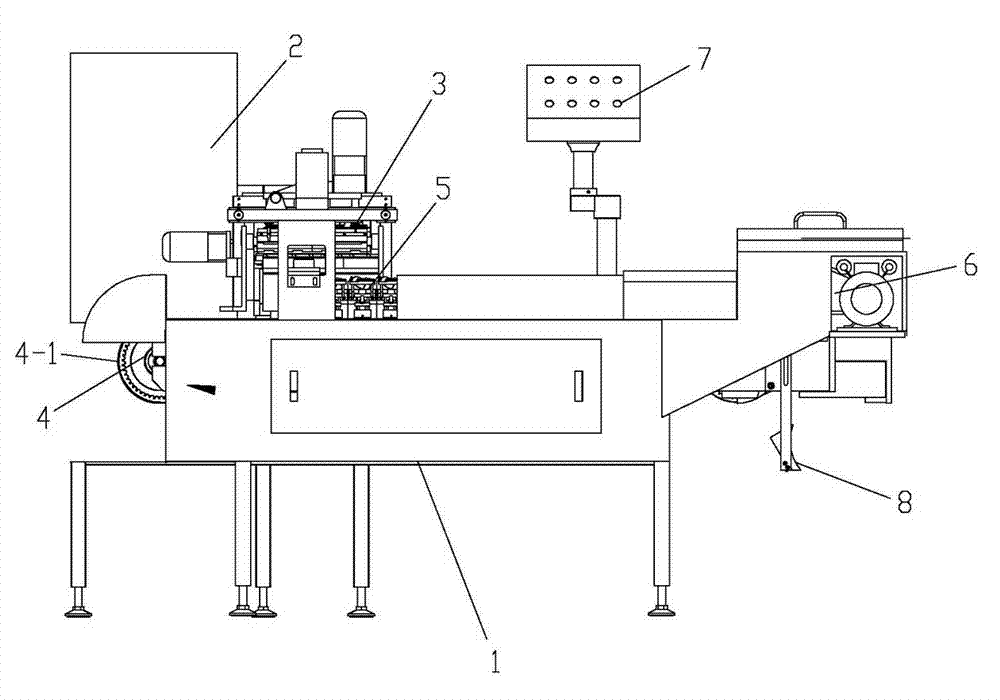

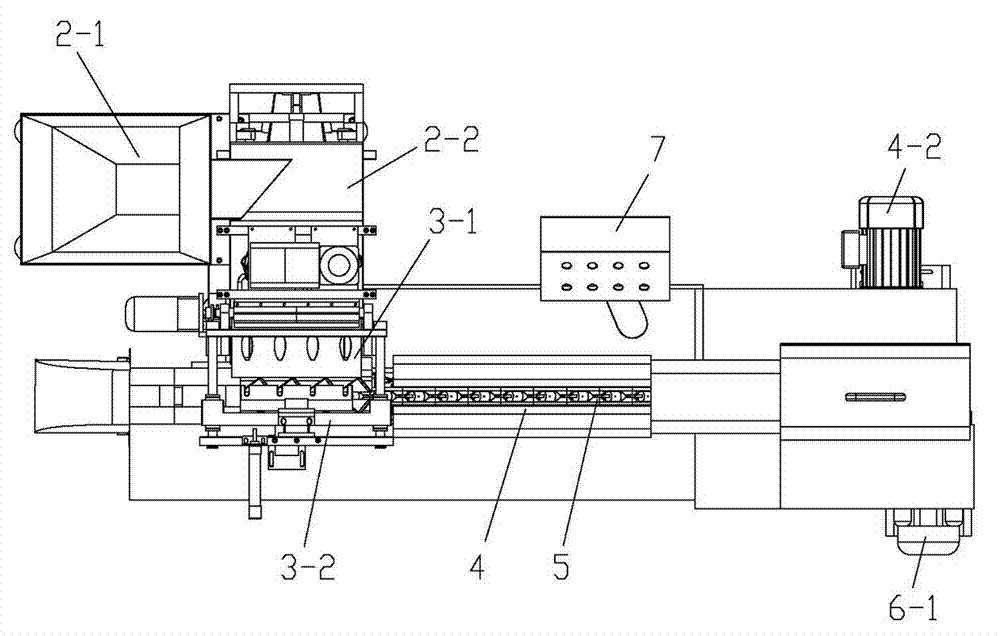

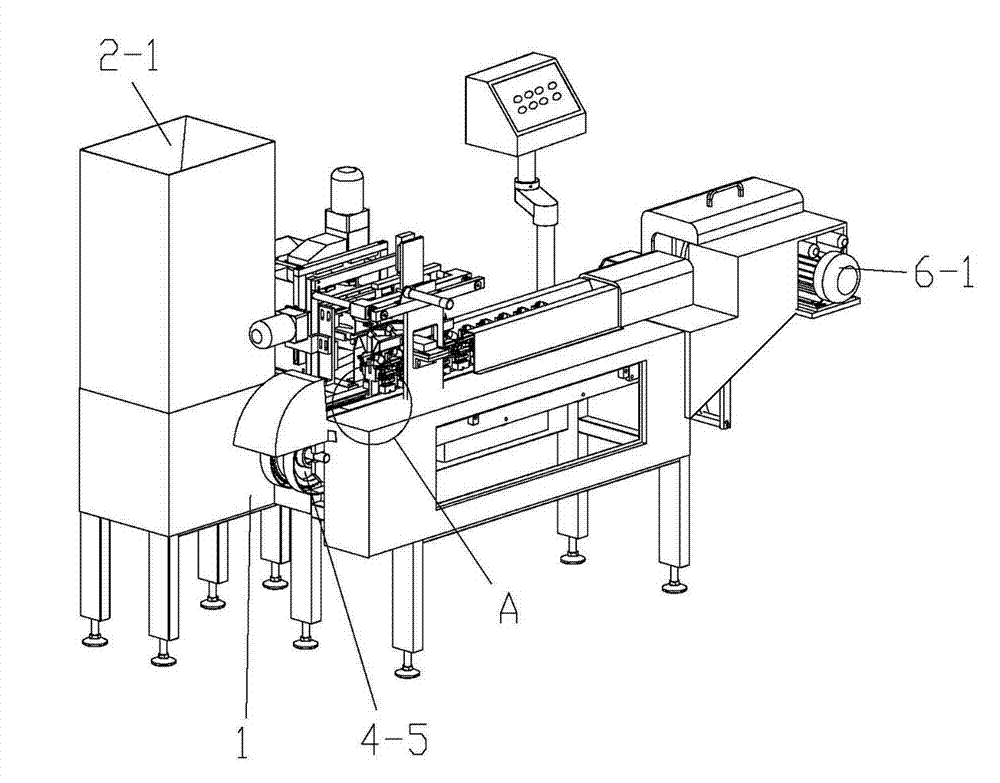

[0036]With reference to accompanying drawing: this betel nut slicer comprises frame 1, is provided with feed mechanism 2, feeding mechanism 3, transmission mechanism 4, locking mechanism 5 and cutting mechanism 6 on frame 1, wherein transmission mechanism 4 comprises transmission motor The driving wheel 4-4 and the driven wheel 4-5 driven by 4-2 are driven by the chain 4-1 between the driving wheel 4-4 and the driven wheel 4-5; the chain 4-1 is fixed with multiple sets of circular reciprocating locks Mechanism 5, locking mechanism 5 comprises fixed seat 5-1, and the bottom of fixed seat 5-1 is provided with the installation hole 5-10 that is fixed on the chain 4-1, and the top of fixed seat 5-1 is provided with the groove that places betel nut Body 5-3, an opening 5-4 is provided in the middle of the tank body 5-3, and the left and right sides of the fixed seat 5-1 are prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com