Terylene strengthened filament weaving pattern wall covering and manufacturing method thereof

A production method and a technology of reinforcing filaments, which are applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of poor stain resistance, poor dimensional stability, and short service life, and achieve strong stain resistance , High stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

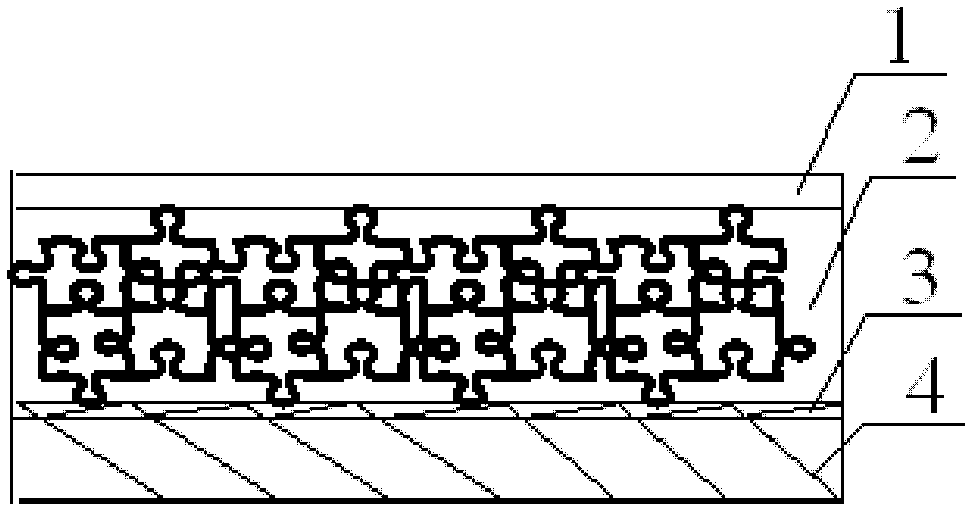

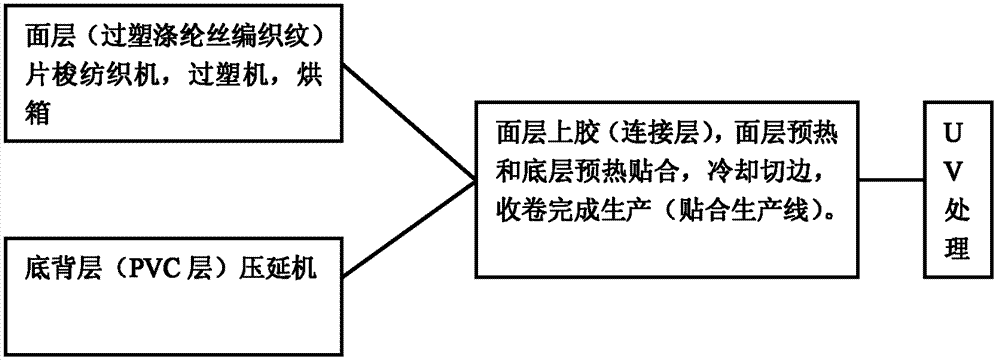

[0035] A polyester reinforced silk weaving pattern wall plastic, its structure is as follows figure 1 As shown, the wall plastic is composed of a surface UV treatment layer 1, a laminated polyester silk weaving layer 2, a PVC cross-linked solidified layer 3 and a bottom and back composite layer 4 from top to bottom. The surface UV treatment layer 1 is coated on the plastic The upper surface of the polyester yarn weaving layer 2, the overplasticized polyester yarn weaving layer 2, the PVC cross-linked solidified layer 3 and the bottom and back composite layer 4 are hot-pressed sequentially from top to bottom to form a layered composite structure. Among them, the surface UV treatment layer 1 is a polyurethane layer cured by ultraviolet light, the over-plasticized polyester yarn braided layer 2 is a high-strength polyester yarn layer plasticized with PVC paste, and the PVC cross-linked curing layer 3 is a PVC layer containing a cross-linking agent. resin layer. The bottom and ba...

Embodiment 2

[0044] A polyester reinforced silk weaving pattern wall plastic, the wall plastic is composed of a surface UV treatment layer, a plasticized polyester yarn weaving layer, a PVC cross-linked solidified layer and a bottom-back composite layer from top to bottom, and the surface UV treatment layer is coated on the The upper surface of the over-plasticized polyester yarn weaving layer, the over-plasticized polyester yarn weaving layer, the PVC cross-linked cured layer and the bottom and back composite layer are hot-pressed sequentially from top to bottom to form a layered composite structure. Among them, the surface UV treatment layer is a polyurethane layer cured by ultraviolet light, the laminated polyester yarn weaving layer is a high-strength polyester yarn layer plasticized with PVC paste, and the PVC cross-linked cured layer is a PVC resin layer containing a cross-linking agent. The bottom and back composite layer is a hot-pressed mixed layer of PVC resin and calcium carbonat...

Embodiment 3

[0061] A polyester reinforced silk weaving pattern wall plastic, the wall plastic is composed of a surface UV treatment layer, a plasticized polyester yarn weaving layer, a PVC cross-linked solidified layer and a bottom-back composite layer from top to bottom, and the surface UV treatment layer is coated on the The upper surface of the over-plasticized polyester yarn weaving layer, the over-plasticized polyester yarn weaving layer, the PVC cross-linked cured layer and the bottom and back composite layer are hot-pressed sequentially from top to bottom to form a layered composite structure. Among them, the surface UV treatment layer is a polyurethane layer cured by ultraviolet light, the laminated polyester yarn weaving layer is a high-strength polyester yarn layer plasticized with PVC paste, and the PVC cross-linked cured layer is a PVC resin layer containing a cross-linking agent. The bottom and back composite layer is a hot-pressed mixed layer of PVC resin and calcium carbonat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap