Elevator operation guide system

A technology for guiding system and elevator operation, applied in the field of guiding system, can solve the problems of complex process, high cost of guide rail production and on-site installation, and achieve the effect of reducing material cost, installation cost and installation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

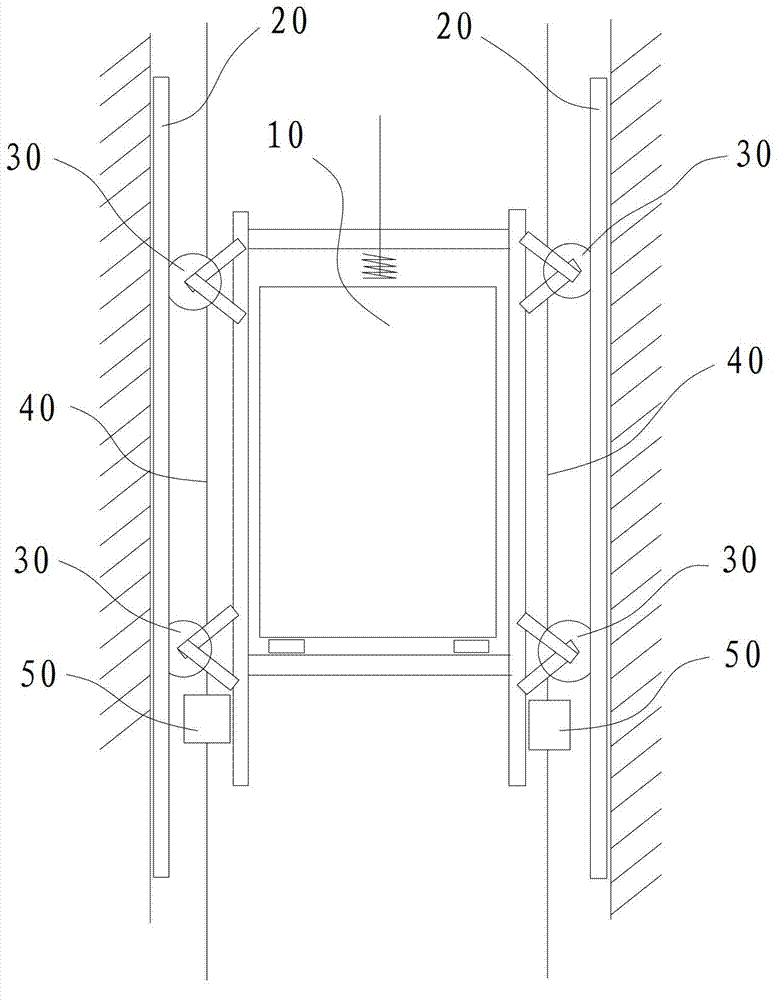

[0017] Such as figure 1 As shown, an elevator operation guidance system includes an elevator car 10, a hoistway guide groove 20, an emergency brake rope 40 arranged in the hoistway outside the car guide shoe 30, and a car arranged on the elevator car 10 Rope clamp 50. The car rope clamp 50 is clamped and connected to the emergency brake rope 40.

[0018] In this embodiment, the emergency brake rope 40 includes steel ropes respectively arranged on both sides of the hoistway, and each of the car rope clamps 50 is connected to one of the steel ropes. The purpose is to ensure the stability of the operation and braking of the elevator car 10.

[0019] In this embodiment, the car guide shoe 30 is slidably or rolled in the hoistway guide groove 20. Set by sliding or rolling, more in line with the requirements of on-site construction.

[0020] In this embodiment, a vibration absorbing mechanism (not shown in the figure) is provided on the car guide shoe 30. The installation of the vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com