Novel automatic bidirectional throttle valve

A two-way throttling valve, automatic technology, applied in the field of mechanical hydraulics, to improve the life of the drilling rig, reduce safety hazards, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0008] Provide the embodiment of the present invention below in conjunction with accompanying drawing as follows:

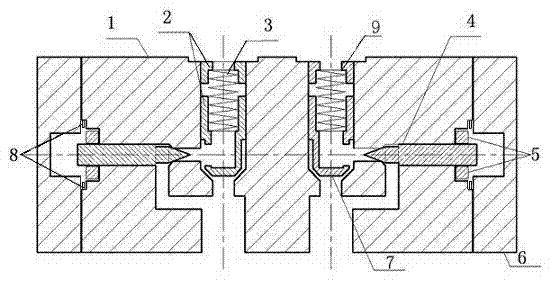

[0009] Such as figure 1 As shown, a novel automatic two-way throttle valve of the present invention is mainly composed of a valve body 1, a check valve 2, a spring 3, a needle valve 4, a lock nut 5, an end cover 6, a valve core 7, a sealing Ring 8 and baffle 9; the one-way valve 2 and the needle valve 4 are symmetrically installed in the valve body 1, the one-way valve 2 is installed vertically in the valve body 1, and the needle valve 4 is installed horizontally in the oil inlet of the valve body 1 On the auxiliary road and the main oil return road, the needle end faces the side with a gap at the lower part of the check valve. Check valve 2 and needle valve 4 can be used together to control the oil flow in the oil inlet and return pipelines of the hydraulic system. Automatic two-way throttling control; the spool 7 of the one-way valve 2 is divided into upper an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com