General movement for split-type household electric range hood

A household electric range fume, split-type technology, applied in the directions of household stoves, household heating, household heating, etc., can solve the problems of high cost, difficult to find faults, and the outer packaging cannot be changed frequently, so as to save costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

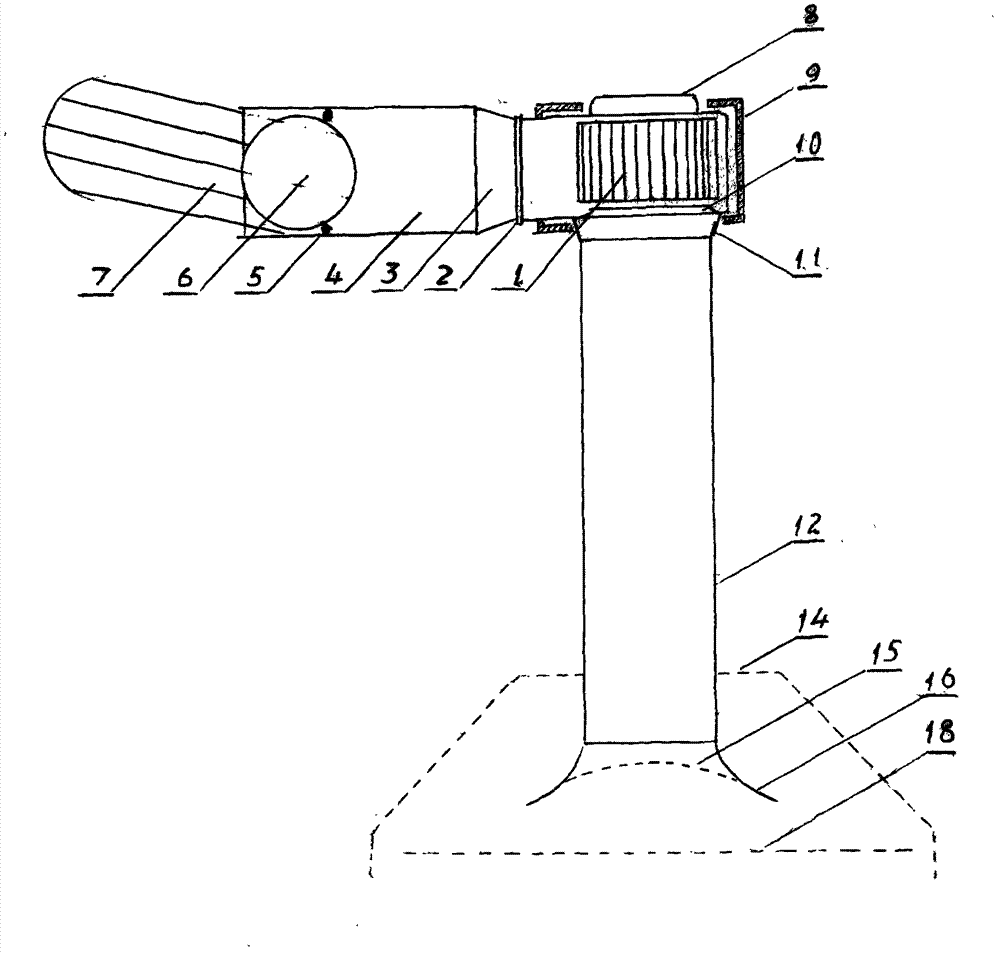

[0027] This embodiment is an embodiment of a stereotyped structure using a centrifugal fan in the present invention.

[0028] Such as figure 1 As shown: the centrifugal fan is equipped with a "vest" type casing 9, which is installed high above the stove, at the same height as the smoke exhaust hole on the wall, and the impeller 1 of the fan is kept horizontal, so that the motor 8 of the fan is open It is exposed on the "neckline of the vest" to facilitate heat dissipation. The air supply port 2 of the fan protrudes horizontally from the "one cuff of the vest". A variable-diameter pipe joint 3 whose interface changes from square to round is installed on the air supply port 2 of the fan to facilitate the smoke exhaust pipe. Choose different pipe diameters. In the previous embodiment, PVC water pipes are selected as the smoke exhaust pipe 4, and the smoke exhaust pipe 4 is installed horizontally and leads directly to the outdoor; five steel wires are combined to form a cage-shape...

Embodiment 2

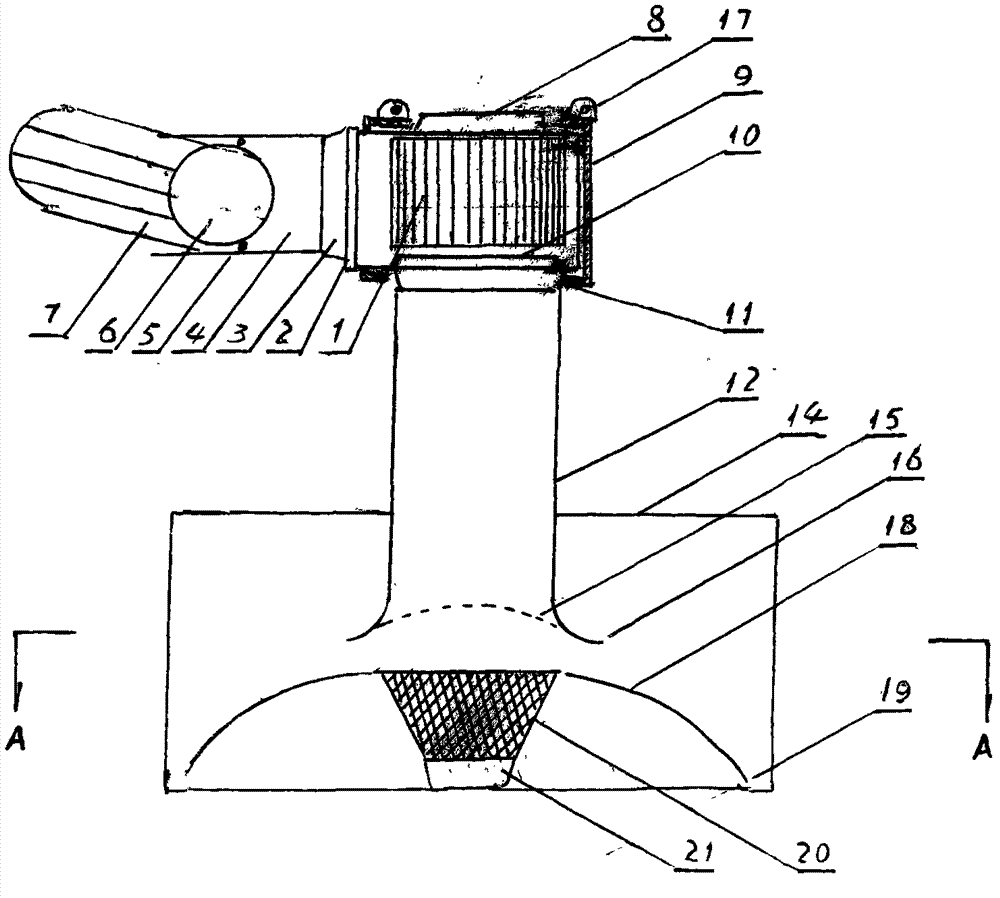

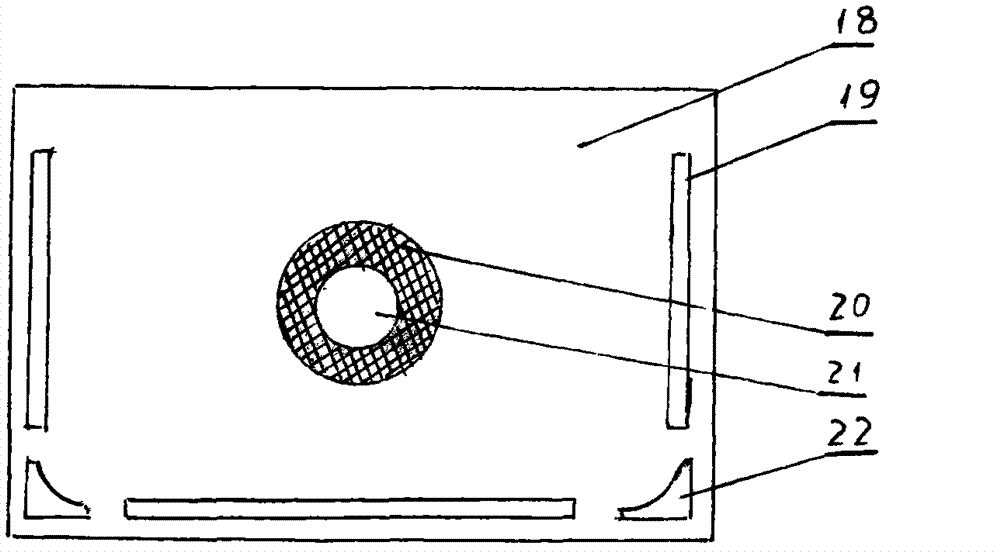

[0031] This embodiment is an embodiment in which the present invention is installed and used in the shell of a deep cover type range hood.

[0032] Such as figure 2 , image 3 As shown: the diameter of the smoke exhaust pipe equipped with the deep-hood range hood in the early days was only 160mm. In the early days, there was no ceiling decoration in the kitchen, and the diameter of the smoke exhaust hole on the wall was mostly only 160mm. "Type housing 9 is provided with ring buckle 17, and the fan is directly installed on the kitchen wall at the same height as the pre-panned smoke exhaust hole on the wall; a variable-diameter pipe joint that changes from square to round is installed on the air outlet 2 of the fan 3. The original accessories are still used, and the PVC pipe with an outer diameter of 160mm is used as the exhaust pipe. 4. It is also of the same specification as the original exhaust pipe. It is directly inserted into the original smoke exhaust hole on the wall,...

Embodiment 3

[0035] This embodiment is an embodiment in which the present invention is installed and used in the casing of a European-style range hood.

[0036] Such as Figure 4 , Figure 5 Shown: Choose an early European-style range hood model CXW238-221 as a reference machine, use its original centrifugal fan (input power 198w, suction port diameter 23cm), and wear a "vest" on the outside of the fan Ring buckle 17 is established below formula shell 9, and blower fan is directly installed on the ceiling 24 of the kitchen; The area of the outlet is 19% larger than the area of the air outlet of the fan. A PVC water pipe with an outer diameter of 200mm is used as the smoke exhaust pipe 4, and a magnetic sealing ring 5 with a cross-sectional diameter of 4mm is arranged at 10cm inside the outlet of the smoke exhaust pipe 4. The outlet of the pipe 4 is obliquely installed with a cage-shaped guide rail 7 composed of five steel wires, and a thin iron shell ball 6 with a diameter of 192mm i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com