Soil grinding and screening device

A screening device and soil technology, which is applied in the field of soil rolling and screening devices, can solve the problems of relying on manual work, harming human health, and low degree of automation, so as to improve screening efficiency, improve stress conditions, and run smoothly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with specific embodiments and drawings, which are explanations of the present invention rather than limitations.

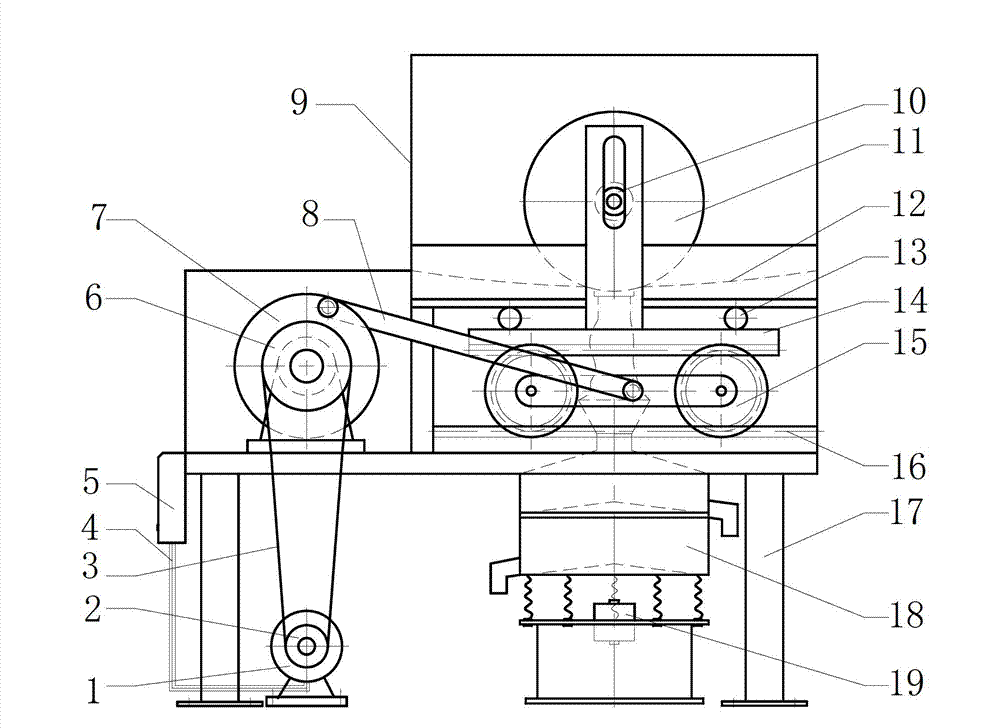

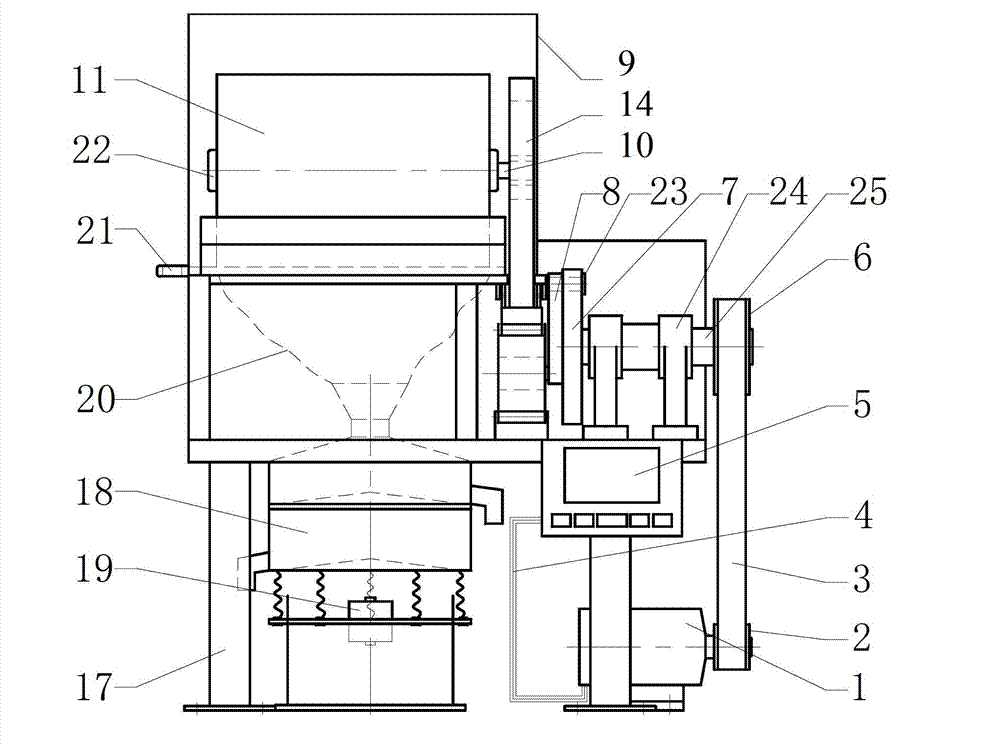

[0028] see figure 1 , figure 2 , a soil rolling and screening device, characterized in that,

[0029] It includes a rolling motor 1, which drives the turntable 7 to rotate through a belt transmission mechanism. The turntable 7 is connected to a gear 15 through a connecting rod 8. The gear 15 is arranged on a rack 16 fixed on the worktable, and at the same time it is connected with the slider 14. The racks at the bottom are engaged, and the slide block 14 is also provided with a chute, and the rotating shaft 10 of the rolling roller 11 is arranged in the chute, and the rolling roller 11 can move horizontally along the groove surface in the rolling groove 12; The pressure groove 12 also has an opening that communicates with the cloth bag 20 arranged below it, and a movable block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com