Random mesh design method of metal net conductive thin film, conductive film and manufacturing method of conductive film

A technology of random mesh and conductive film, applied in cable/conductor manufacturing, conductive layer on insulating carrier, circuit, etc., can solve the problems of Moiré fringe transmittance and difference, and avoid the generation of moiré fringes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

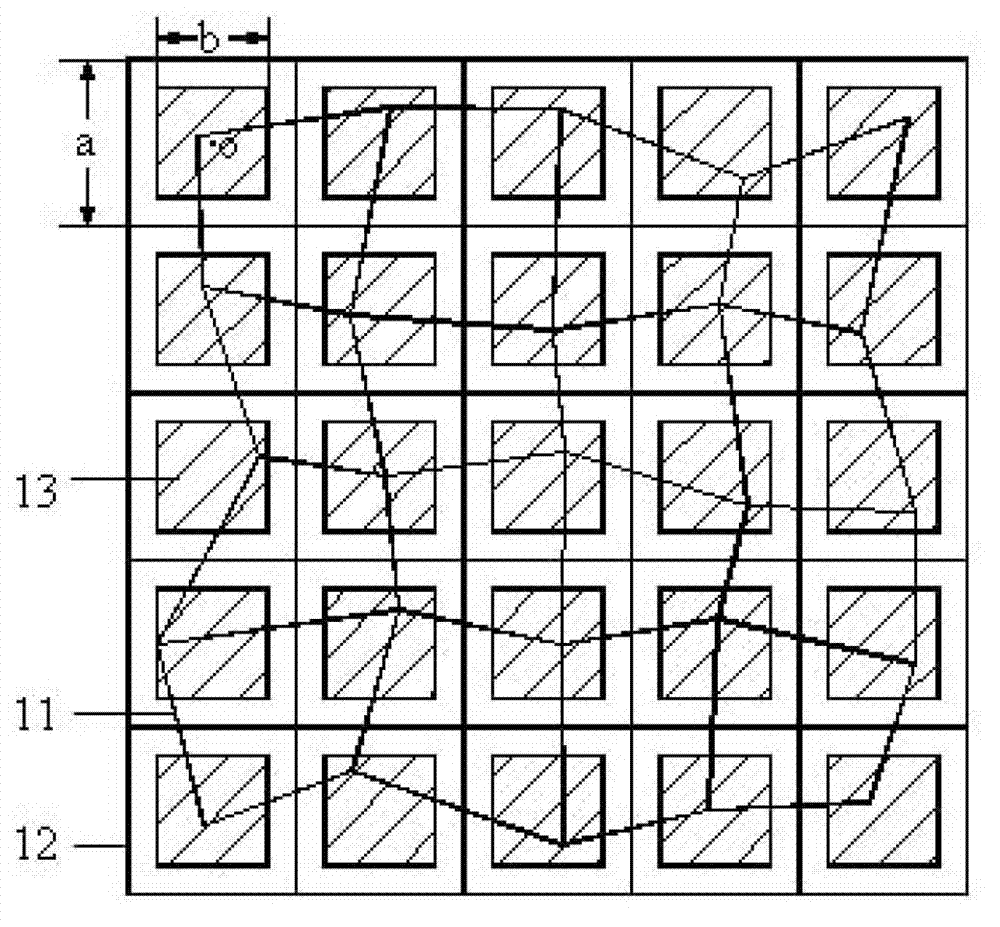

[0047] In this embodiment, the type of random grid is a trapezoidal grid, such as figure 1 11 in. First, a rectangular coordinate system is established in a two-dimensional plane space, and a square 12 is drawn in the rectangular coordinate system. The coordinates of the four vertices of the square 12 are (0,0), (a,0), (a,a), (0, a), the squares 12 are arrayed in a two-dimensional plane, and the periods along the x and y directions are a , to form a regular grid of squares; then define an effective area within each square that can generate random points, the center of the effective area and the center of the square o same as figure 1 Shown in the shaded area 13 in , and generate random points in the effective area 13, the effective area is also a square in this embodiment, and the side length isb ; Finally, connect random points inside the same row of squares, and connect random points inside the same column of squares to form a random grid composed of trapezoids. Based on ...

Embodiment 2

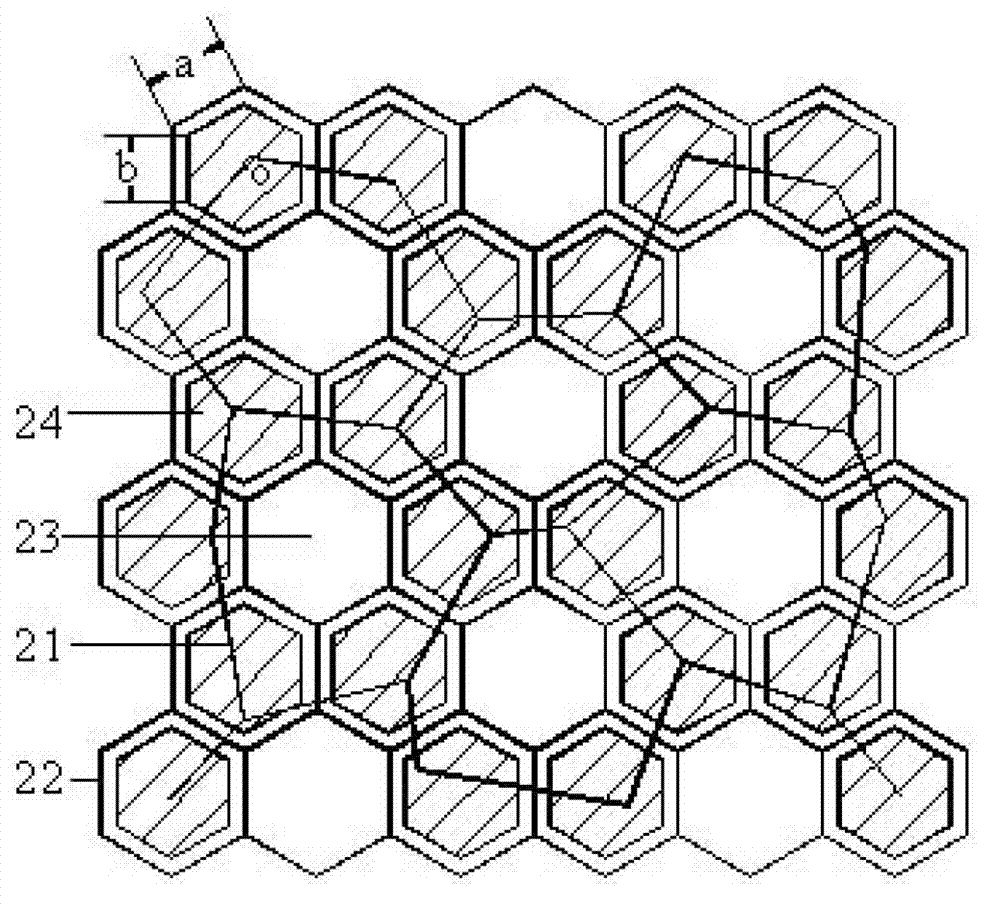

[0049] In this embodiment, the type of random grid is an irregular hexagonal grid, such as figure 2 21 in. Similar to Embodiment 1, first establish a rectangular coordinate system in a two-dimensional plane space, draw a regular hexagon 22 in this rectangular coordinate system, and the side length is a , the regular hexagons 22 are arrayed in a two-dimensional plane to form a typical honeycomb grid; then a regular hexagon is selected as the center 23, and random points can be generated by defining inside the six regular hexagons adjacent to the center The effective area of , the center of the effective area and the center of each regular hexagon o Similarly, in this embodiment, the effective area is also a regular hexagon, and the side length is b ,Such as figure 2 As shown in the shaded area 24 in , random points are generated in the effective area 24, and the generated random points are connected clockwise in pairs to form an irregular hexagon; finally, another regula...

Embodiment 3

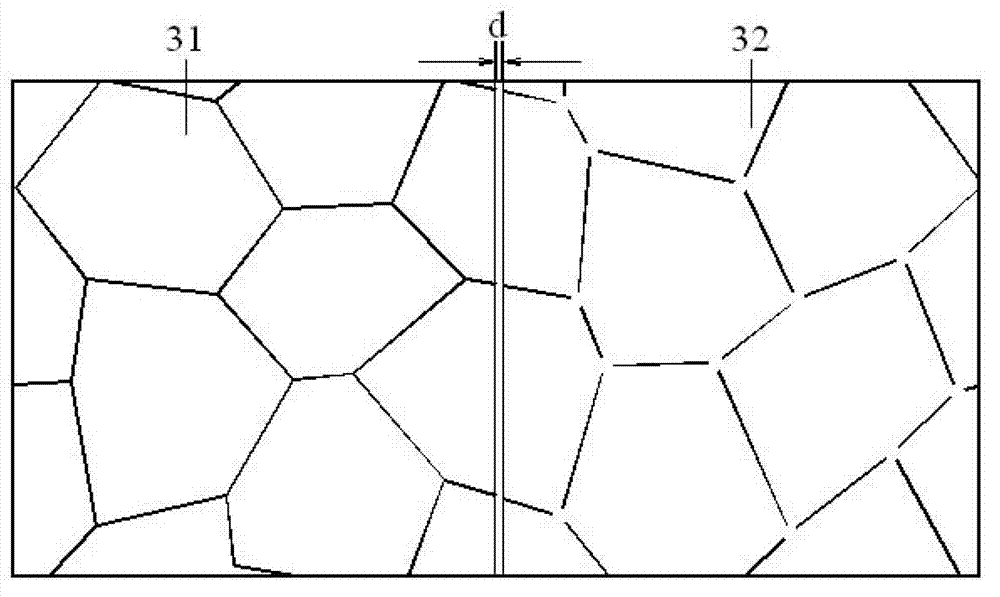

[0051] In this embodiment, the type of the random grid is an irregular hexagonal grid, and the generation method is as described in Embodiment 2. Such as image 3 As shown, the left shaded area is the conductive area 31 of the metal mesh conductive film, and a continuous hexagonal random grid is laid in the area; the right area is the insulating area 32 of the metal mesh conductive film, and the hexagonal grid with disconnected nodes is laid in the area. Random mesh of polygons; width between conductive region 31 and insulating region 32 d Separated by the blank area, so as to achieve electrical isolation. In this example d It is 10μm, which is invisible to the naked eye after testing. Since the grid type and density of the conductive area and the insulating area are exactly the same, that is, the shading ratio of the grid lines in the two areas is the same, so obviously the transmittance is also exactly the same, so there will be no gray scale change. The method of node d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com