Photoetching method

A technology of lithography and lithography equipment, applied in the field of lithography, can solve problems such as lithography pattern distortion, and achieve the effect of reducing the degree of distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

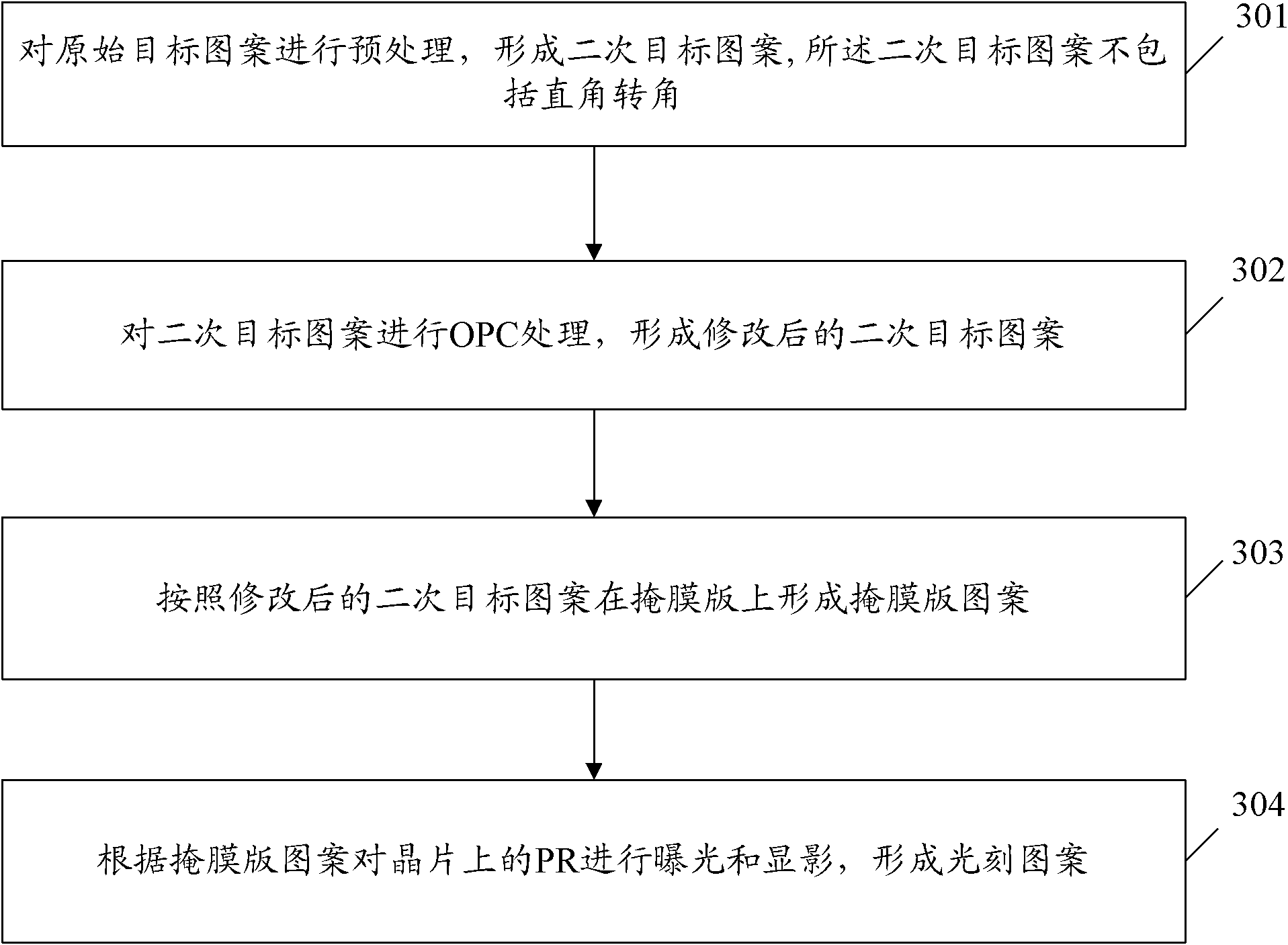

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the solutions of the present invention will be further described in detail below with reference to the accompanying drawings and examples.

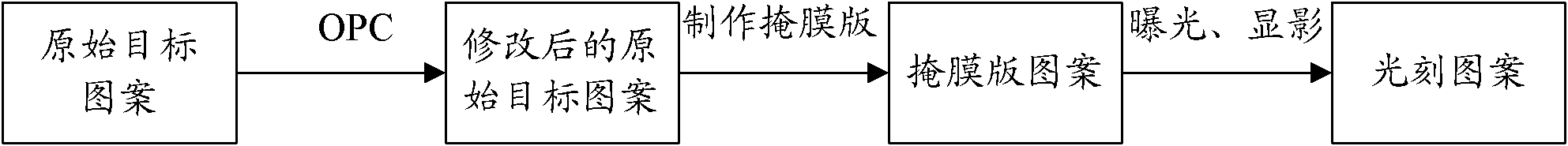

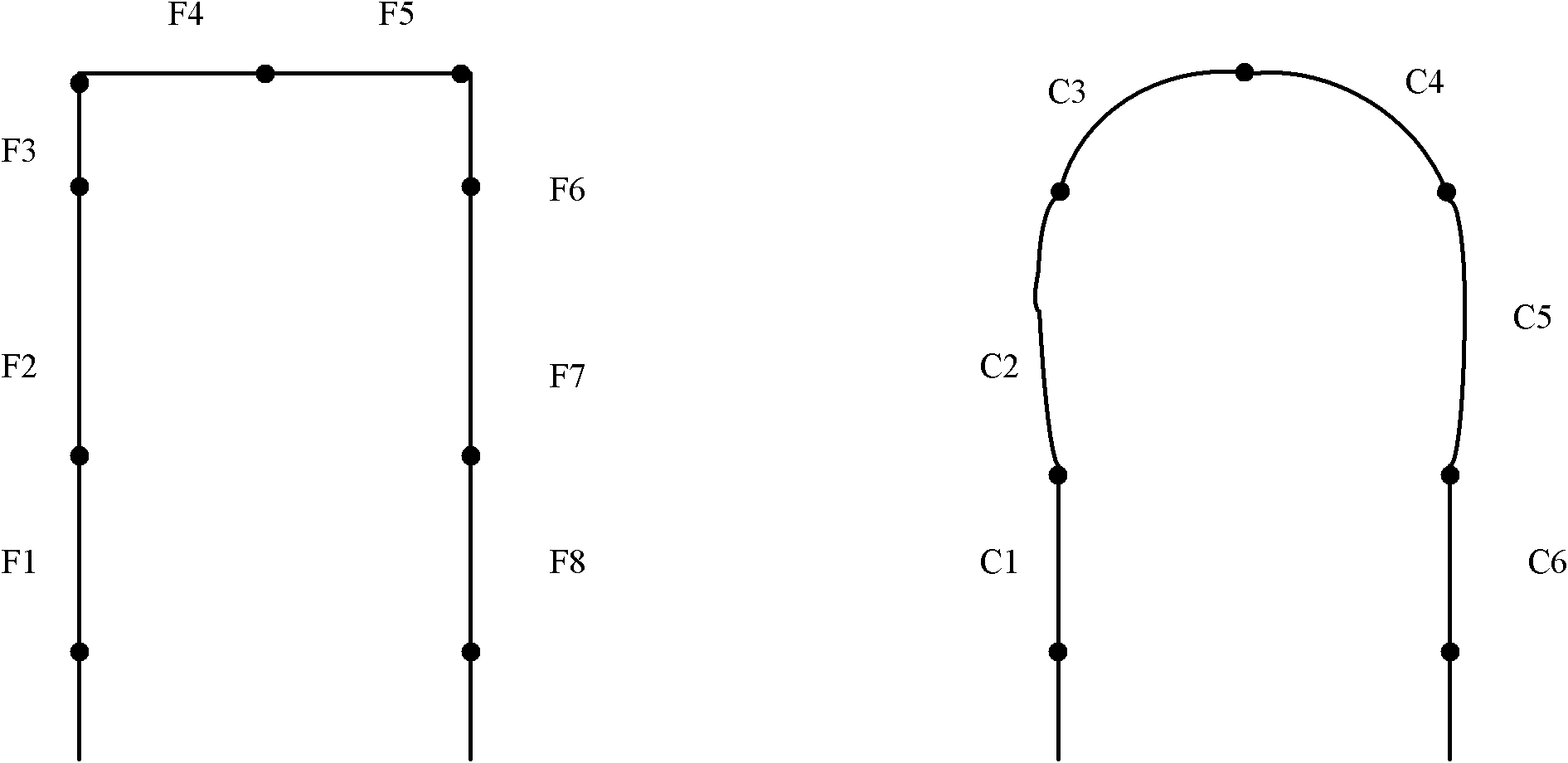

[0037] The core idea of the present invention is: in the prior art, OPC processing is directly performed on the original target pattern, and the processed pattern is used as a mask pattern. Since the right-angle corner feature in the original target pattern is strengthened during OPC processing, the resulting The additional effect is exactly that the graphics near the right-angled corner may be distorted; and in the present invention, the original target pattern is first preprocessed to form a secondary target pattern that does not include the right-angled corner, and then the secondary target pattern is OPC processed. Since the secondary target pattern does not have the right-angle corner feature, the problem of distortion of the grap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com