Interlayer film for laminated glass and laminated glass containing same

A technology of laminated glass and interlayer film, applied in the field of interlayer film and laminated glass, which can solve problems such as insufficient, limited processing direction, and difficulty in degassing air from laminated glass, so as to improve degassing performance, increase degassing performance, and improve Dealing with operational effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0053] Preparation example 1, the preparation of polyvinyl butyral interlayer film

[0054] 100 kilograms of polyvinyl butyral resin and 35 kilograms of ADK CIZER RS-107 plasticizer (purchased from Changjiang Chemical Co., Ltd.) were added to the high-strength extrusion mixer, and the temperature was maintained in the range of 190 to 193 ° C. After mixing the butyral resin and the plasticizer mixture for about 5 minutes, the extruded melt is forced to pass through a film-forming die, extruded into a thin sheet of about 0.76 mm, cooled by cooling water and coiled to obtain polyethylene without patterns The preparation of the butyral interlayer, the interlayer has the original surface texture, the polyvinyl butyral interlayer, through the surface roughness analyzer (brand: Kosaka Laboratory Ltd., model: SURFCORDER SE1200) to measure its surface texture The average surface roughness is measured to be 34.7 μm.

Embodiment 1

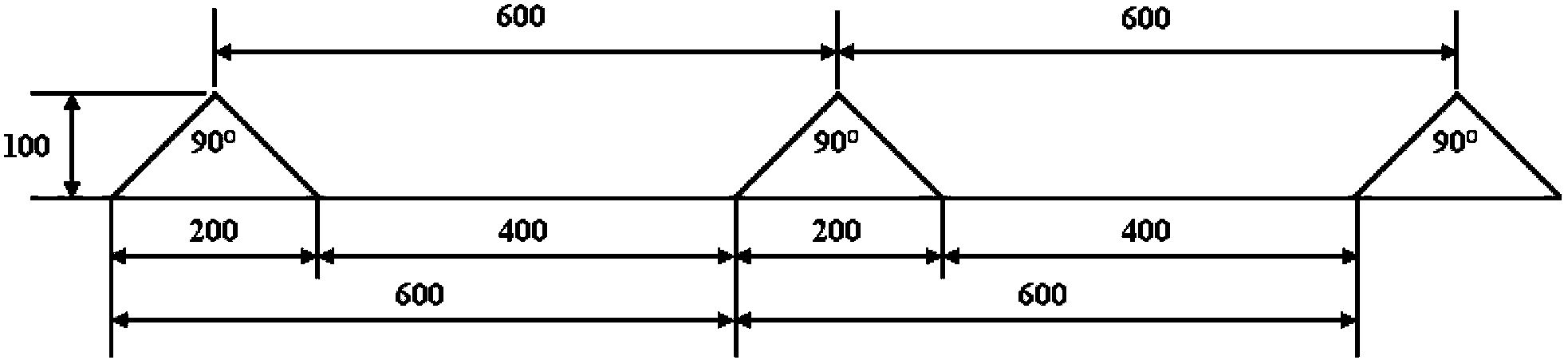

[0055] Embodiment 1, preparation of interlayer film A1 for laminated glass of the present invention

[0056] The polyvinyl butyral interlayer film of Production Example 1 was cut into a square of 35 cm×35 cm, and the polyvinyl butyral interlayer film was preheated to 65-75° C. before performing double-sided pressing. The pressing conditions are embossing roller temperature 130°C, pressure 30kg / cm 2 , the pattern on the embossing roller is complementary to the approximately circular protrusions that the intermediate film wants to have, the minimum diameter is 280 μm, the maximum diameter is 400 μm, and the average diameter is about 300 μm, and the height of the apex of the protrusion is about 65 to 70 μm. The center point spacing of each adjacent protrusion is about 380 to 400 μm, and the shape, diameter, height of each protrusion apex and the center point spacing of each adjacent protrusion can be the same or different irregular pattern The debossed pattern, to extrude the em...

Embodiment 2

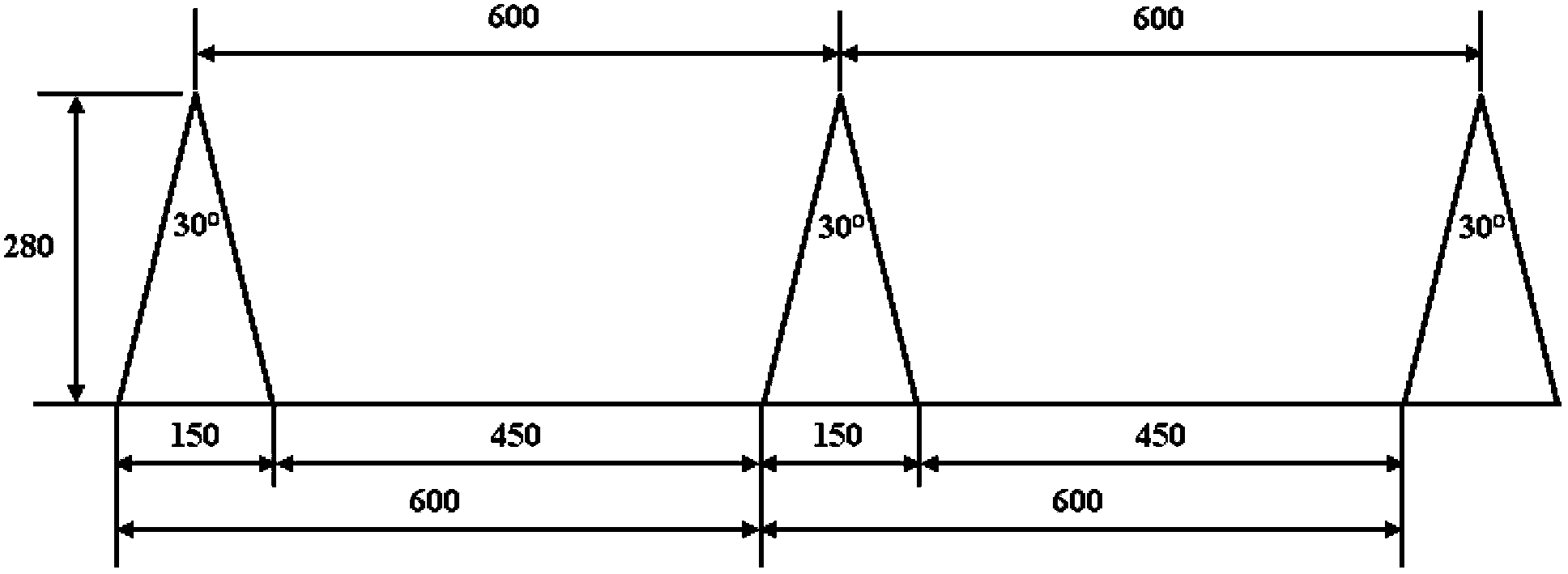

[0057] Embodiment 2, preparation of interlayer film A2 for laminated glass of the present invention

[0058]The conditions are the same as in Manufacturing Example 1, except that the pattern on the embossing roller is replaced by an approximately circular protrusion that is complementary to the intermediate film. The maximum diameter is 450 μm, the minimum diameter is 350 μm, and the average diameter is About 400 μm, the height of the apex of each protrusion is about 85 to 90 μm, the distance between the center points of each adjacent protrusion is about 780 to 800 μm, and the shape, diameter, height of each protrusion apex and each adjacent protrusion are approximately circular. The central point spacing of the protrusions can be the same or different irregular patterns and concave patterns, which are pressed by embossing rollers that press out the interlayer film under the above conditions, that is, the pressing operation is completed, and the interlayer film A2 for laminated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface average roughness | aaaaa | aaaaa |

| The maximum diameter | aaaaa | aaaaa |

| Minimum diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com