Waste liquid treatment device

A waste liquid treatment and waste liquid technology, which is applied in nuclear engineering, radioactive purification, etc., can solve the problems of inability to install a variety of highly immersed membranes, inconvenient operations, and time-consuming, so as to improve simplicity, increase processing capacity, The effect of reducing the risk of radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the configuration and functions of preferred embodiments of the present invention will be described in detail with reference to the drawings.

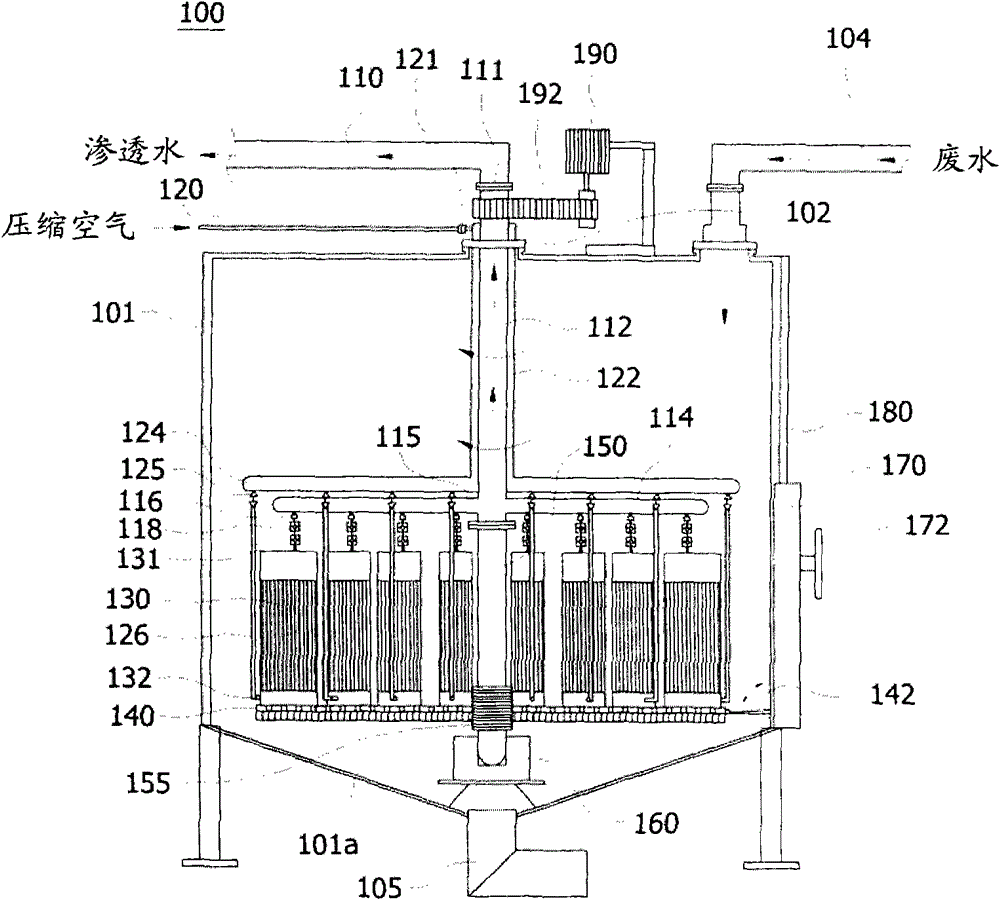

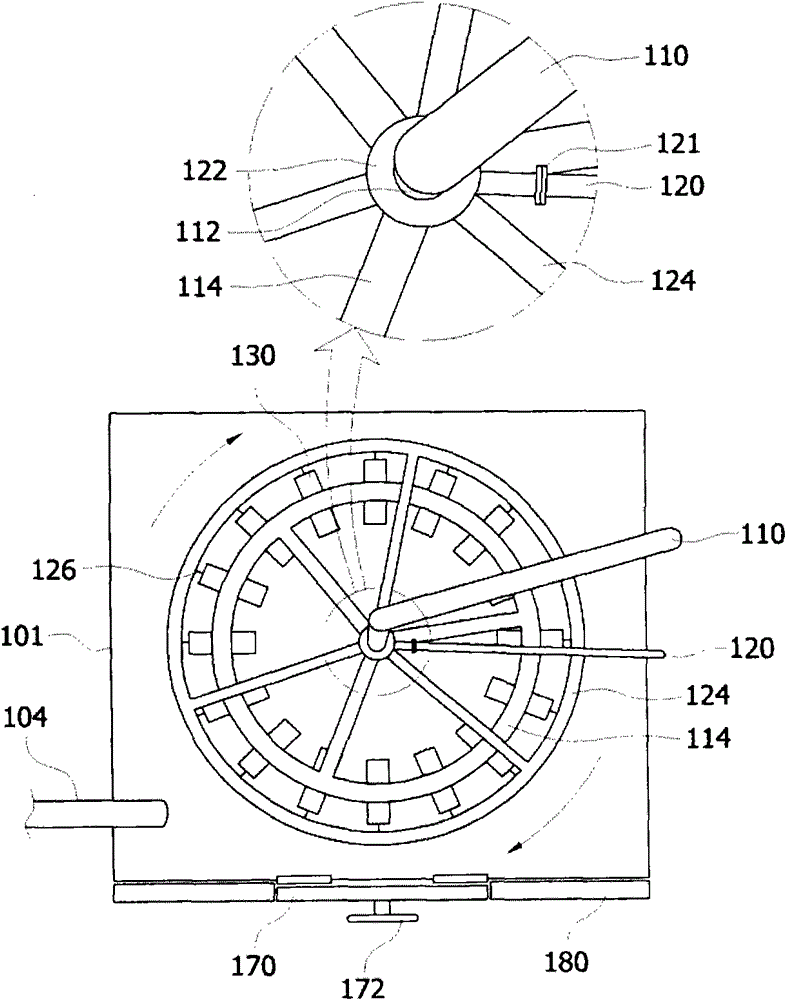

[0031] figure 1 It is a side view of the waste liquid treatment device provided by the present invention in which the submerged membrane is arranged in a ring shape. figure 2 It is a top view of the waste liquid treatment device provided by the present invention in which the submerged membrane is arranged in a ring shape.

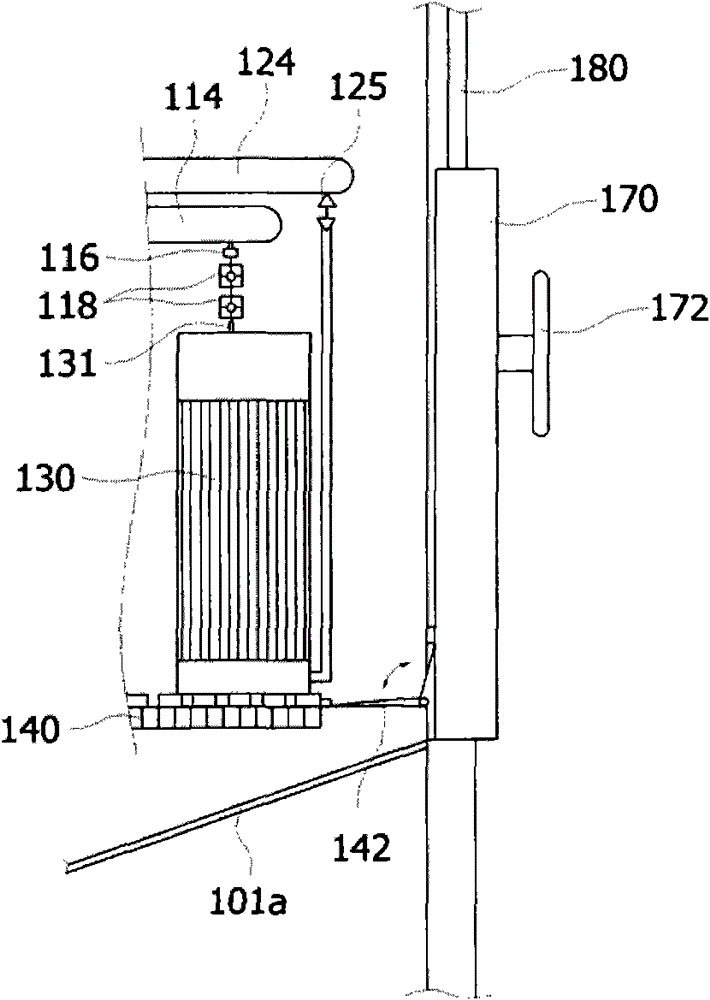

[0032] The characteristics of the waste liquid treatment device of the present invention include increasing the waste liquid treatment capacity in the solid-liquid separation tank 100, improving the ease of replacement of the submerged membrane 130, and improving the connection and fixing methods of the submerged membrane 130.

[0033] In order to achieve such a purpose, the solid-liquid separation tank 100 of the wastewater treatment device of the present invention is composed as a whole to in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com