Transformer lead manufacturing tool

A technology for making tools and transformers, which is applied in coil manufacturing, contact manufacturing, etc., can solve the problems of no specific methods or tools, huge investment in automation equipment, poor quality assurance, etc., and achieve simple structure, low investment, and beautiful appearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

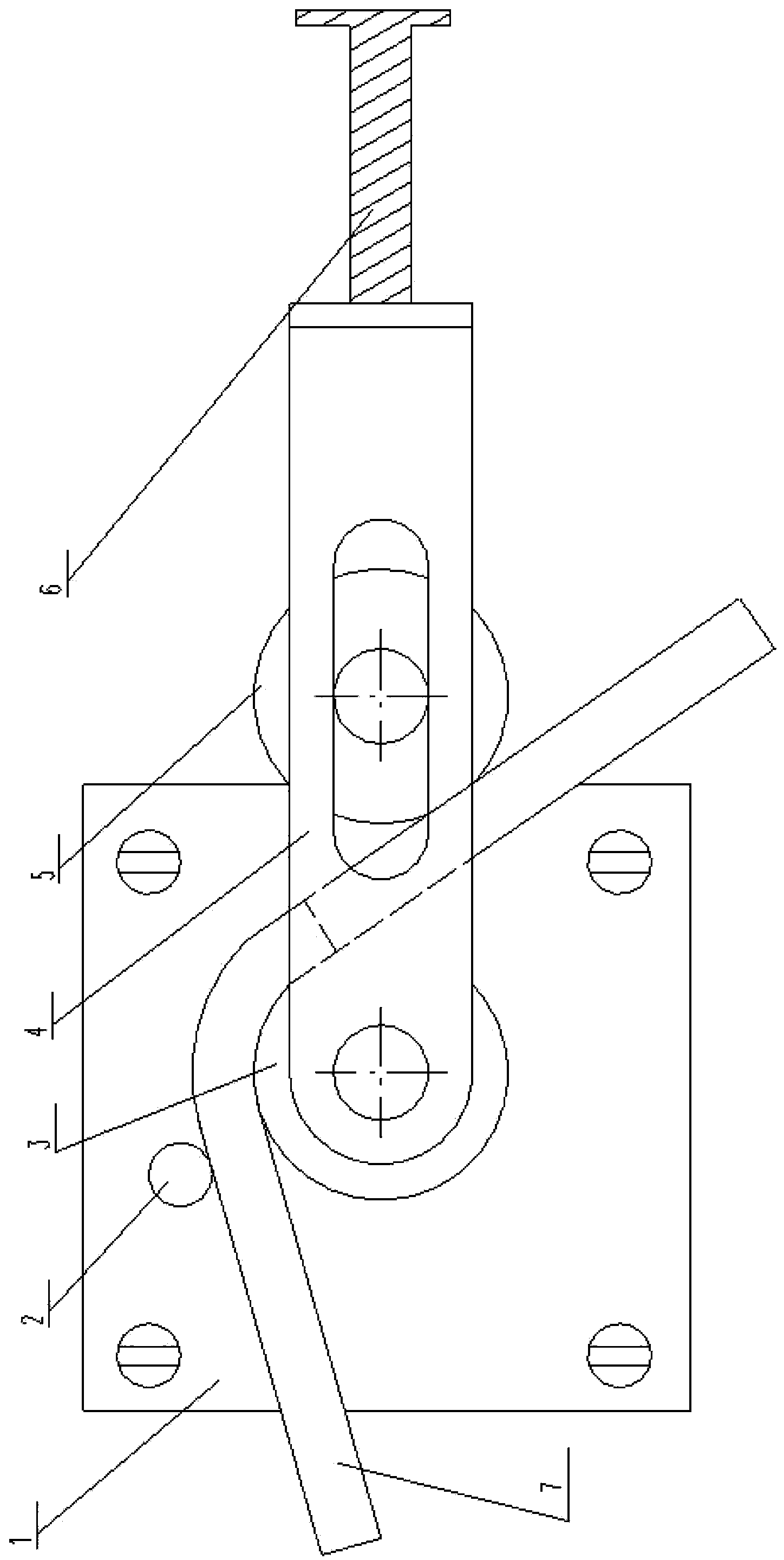

[0010] like figure 1 As shown, the square base 1 is installed on the console through four mounting holes thereon, and the wheel surfaces of the fixed roller 3 and the moving roller 5 are provided with arc grooves, and the fixed roller 3 is fixed at the center of the base 1 The front end of the handle bracket 4 is movably connected with the center of the fixed roller 3 through a shaft, and the handle bracket 4 can rotate around the shaft; the middle part of the handle bracket 4 is provided with an axially adjusting long hole; the moving roller 5 is installed in the adjusting long hole through a fixed bracket Above; the adjusting screw rod 6 is installed at the tail end of the handle bracket 4, the front end of the adjusting screw rod 6 faces the moving roller 5, and through the cooperation with the fixed bracket, in the process of rotating the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com