Manufacturing method of pixel structure

A fabrication method and technology of pixel structure, which are applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem that the photomask is expensive, the manufacturing cost of the pixel structure 90 cannot be effectively reduced, and the manufacturing cost of the pixel structure 90 cannot be reduced. and other problems, to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

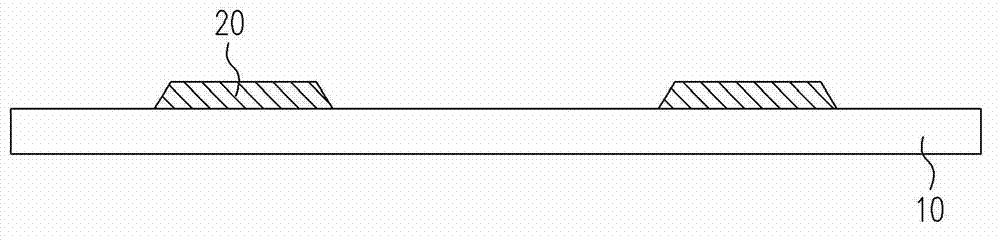

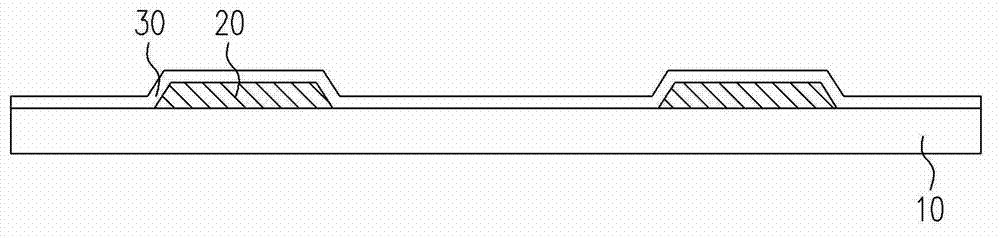

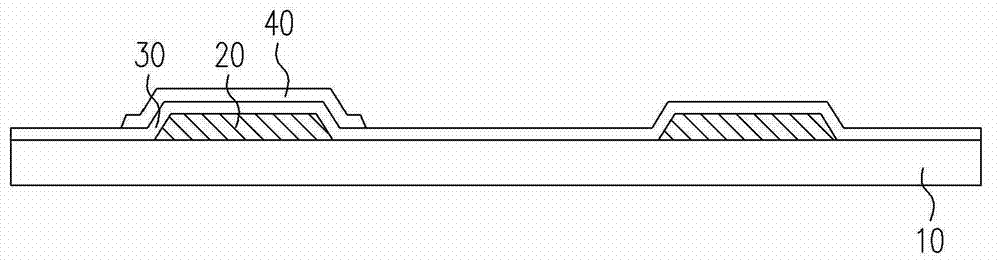

[0052] Figure 2A~Figure 2G It is a schematic diagram of a manufacturing method of a pixel structure of the present invention. Please refer to Figure 2A Firstly, the substrate 200 is provided, and the material of the substrate 200 is, for example, hard or soft materials such as glass and plastic. Next, a first conductive layer 210 is formed on the substrate 200, wherein the first conductive layer 210 is formed by, for example, sputtering, evaporation or other thin film deposition techniques.

[0053] Next, if Figure 2B As shown, a first mask S1 is provided above the first conductive layer 210 , and the first mask S1 exposes a portion of the first conductive layer 210 , and a laser L is used to irradiate the first conductive layer 210 through the first mask S1 . In detail, the first conductive layer 210 irradiated by the laser L absorbs the energy of the laser L and is ablated from the surface of the substrate 200 . Specifically, the energy of the laser L used to peel off...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com