Light emitting diode package and method for manufacturing same

A technology for light-emitting diodes and a manufacturing method, which is applied to electrical components, electric solid-state devices, circuits, etc., can solve the difficulty of optical power or brightness and its color rendering, the complex manufacturing process of light-emitting diode units, and the increase in manufacturing costs of light-emitting diode units, etc. problems, to achieve the effect of being conducive to thinning, reducing thickness, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, preferred embodiments of the light emitting diode package and its manufacturing method according to the present invention will be described in detail.

[0040] The features and advantages of the light emitting diode package and its manufacturing method according to the present invention will be more clearly understood through the detailed description of the following embodiments.

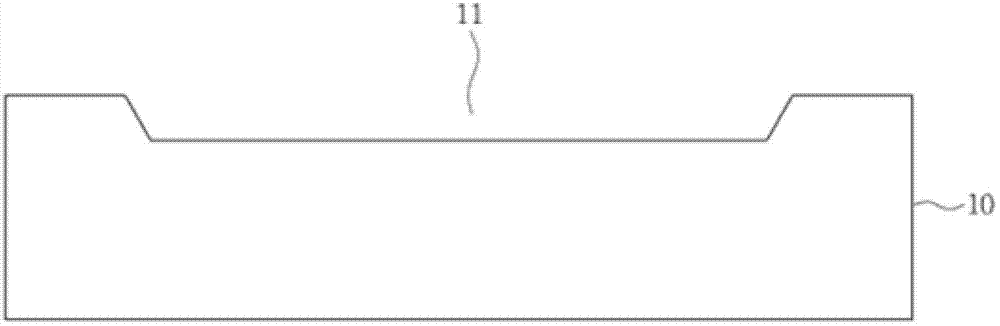

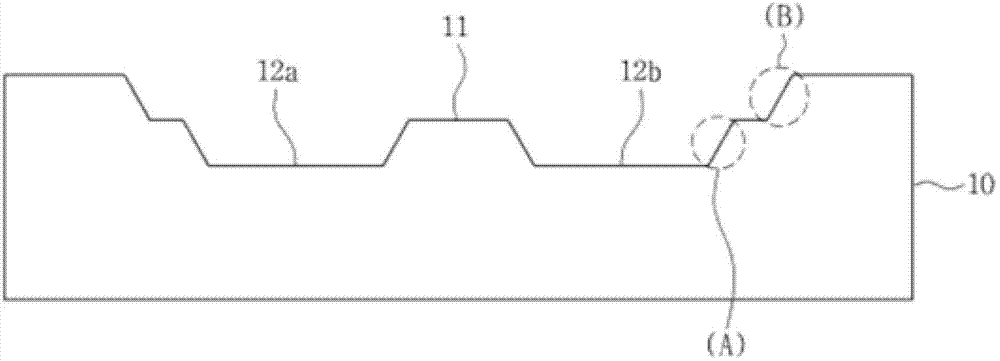

[0041] Figure 1a to Figure 1f is a process cross-sectional view for manufacturing a light emitting diode package according to the present invention, figure 2 is an enlarged structural view of the chip bonding area of the light emitting diode package according to the present invention.

[0042] In the present invention, a heat dissipation substrate with a multi-layer reflective surface is used, and the wiring pattern layer is extended to the lower lower surface of the chip mounting area, thereby ensuring the ease of the chip bonding process and reducing the thickness of the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com