Multilayer channel member and ultrasonic fluid measuring device using same

A technology of flow path components and fluid meters, which is applied in the direction of measuring devices, liquid/fluid solid measurement, flow measurement/mass flow, etc., can solve the problems of measurement accuracy reduction, cost increase, size deviation, etc., and improve the side plate Effects of strength, improvement of measurement accuracy, and simple configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

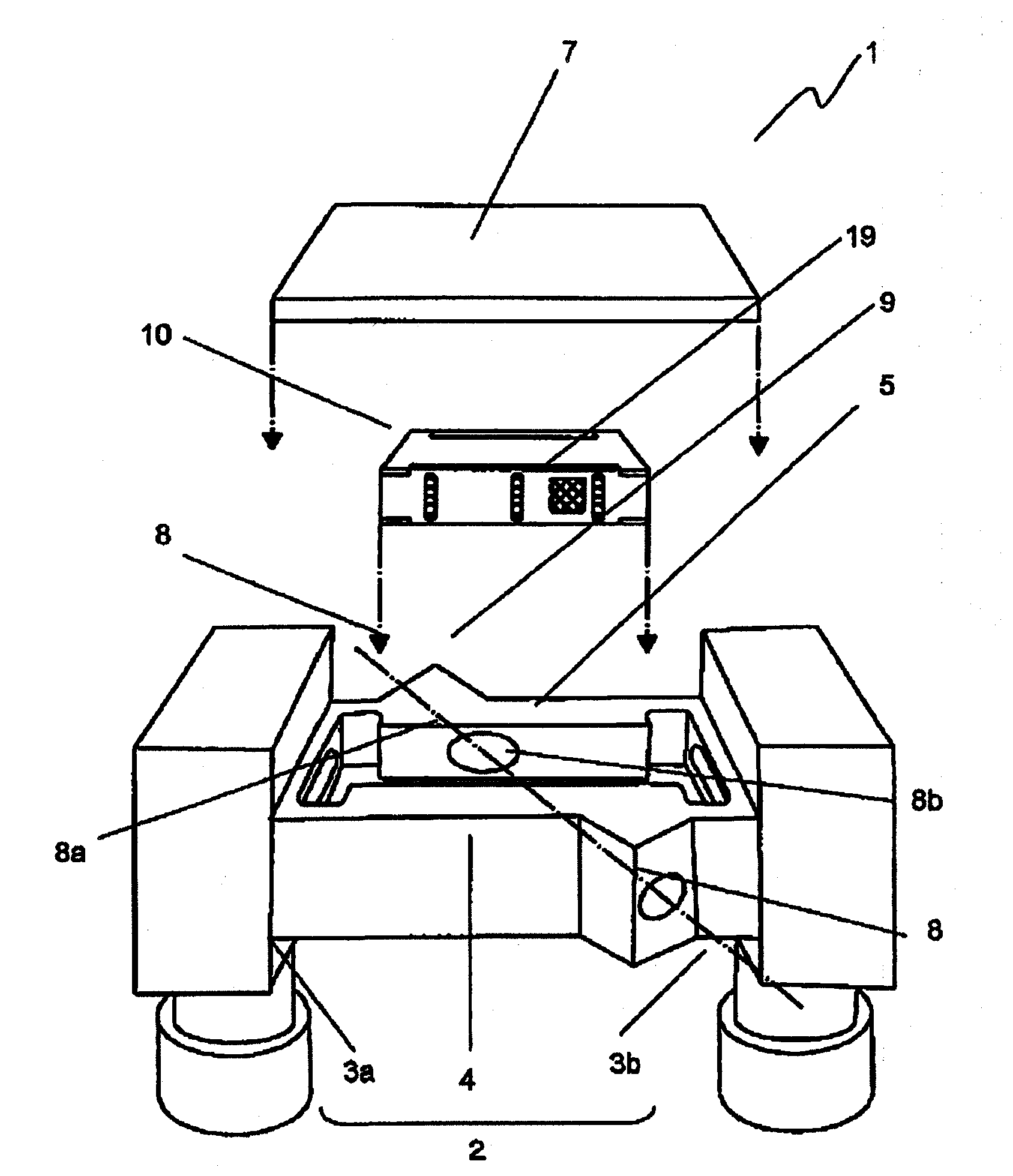

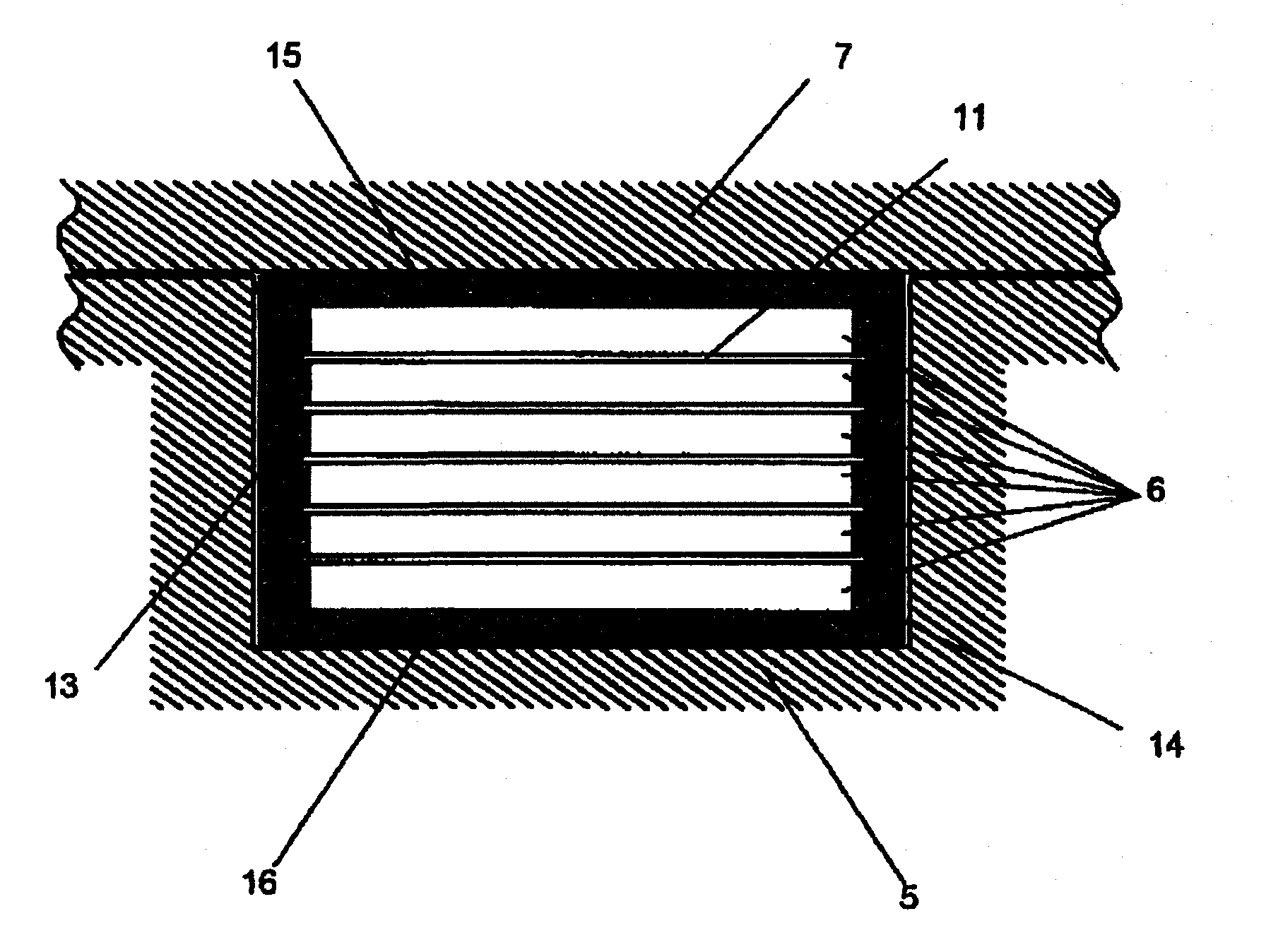

[0076] exist Figure 1~4 Among them, the fluid channel 2 of the ultrasonic fluid measuring device 1 is formed in a substantially inverted U-shape by left and right vertical channels 3a, 3b and a horizontal channel 4 connecting the upper ends of the left and right vertical channels 3a, 3b.

[0077] The horizontal flow path 4 has a square tube-shaped measurement flow path housing portion 5 with an upper opening for measuring fluid, and the measurement flow path housing portion 5 is provided with two transmitting and receiving wave channels in a pair-to-pair manner. The ultrasonic measurement unit 9 having a transmitter and receiver (not shown) is provided on the instrument mounting unit 8, respectively.

[0078] In addition, the measurement channel housing part 5 has a multilayer channel member 10 that divides the fluid into a plurality of flat channels, and a cover part 7 that houses the multilayer channel member 10 in the measurement channel housing part 5 and seals it. .

...

Embodiment approach 2

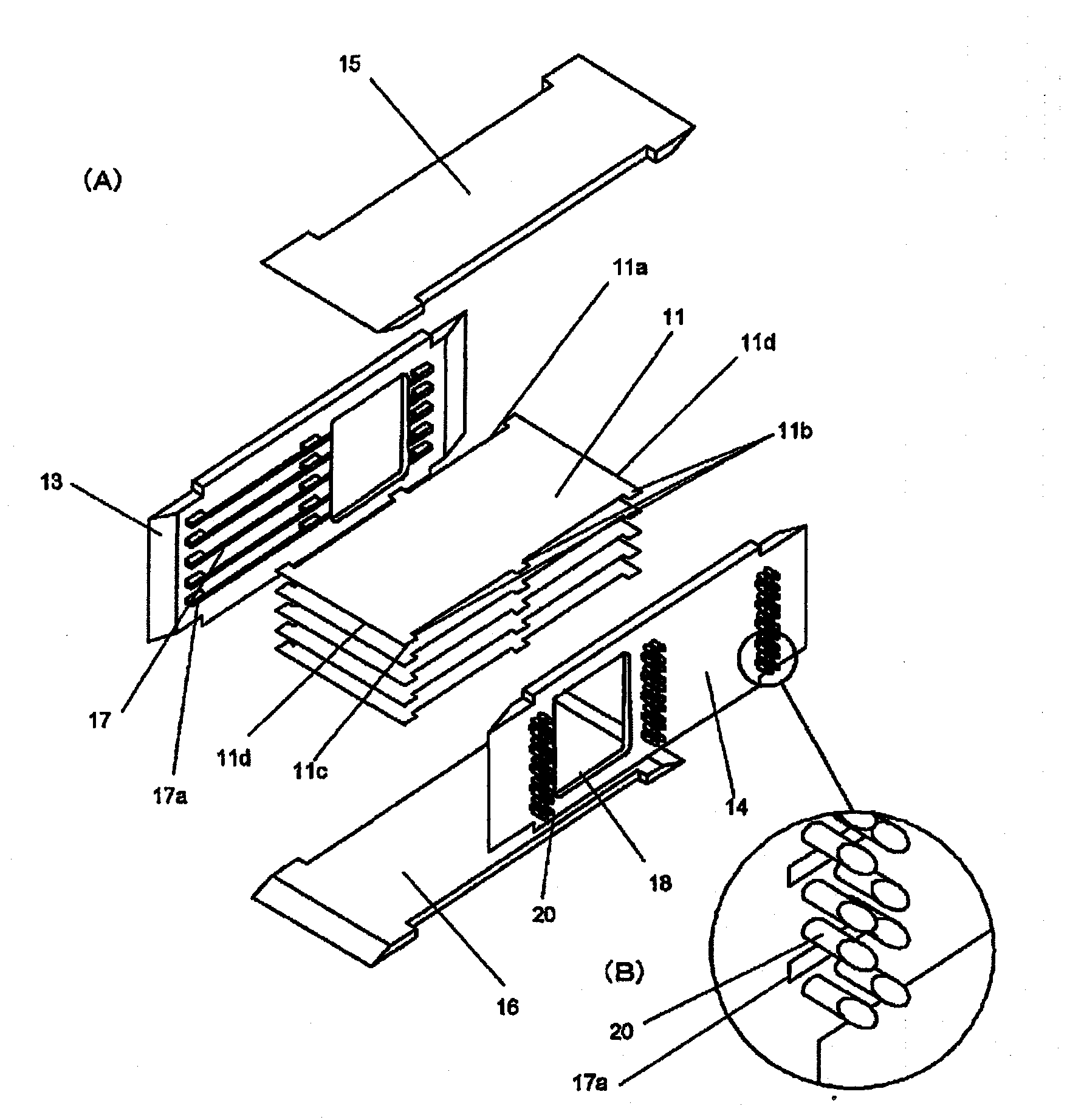

[0097] Figure 5-7 shows Embodiment 2 of the present invention, and has image 3 , 4 Components with the same function are assigned the same reference numerals, and the content of Embodiment 1 is referred to for the specific description.

[0098] like Figure 5 , Image 6 As shown, the melting protrusions 25 provided above and below the insertion hole 17a into which a part of the separator 11 is inserted have the welding surface at the front end portion inclined in the vertical direction, and the shape is changed, that is, the height is changed, and the separator 11 is changed. The amount of fusion of the melting protrusions 25 provided above and below the insertion holes 17a, 17a of the side plates 13, 14 differs on the upper and lower sides of the partition 11, and the gap between the insertion holes 17a and the partition 11 is formed in a certain direction.

[0099] Alternatively, assemble as Figure 7 As shown, a positioning jig 30 having slits 32 set to space the par...

Embodiment approach 3

[0117] like Figure 9 As shown, the fluid channel 202 of the ultrasonic fluid measuring device 201 is formed in a substantially inverted U-shape by the left and right vertical channels 203a, 203b, and the horizontal channel 204 connecting the upper ends of the left and right vertical channels 203a, 203b. .

[0118] The horizontal flow path 204 has a measurement flow path housing portion 205 with a rectangular cross-section and an open upper surface, and a transmitter / receiver mounting portion 206 is formed on the opposite short side wall portion thereof, constituting an ultrasonic measurement portion 207 .

[0119] Furthermore, a multilayer flow path member 208 that divides the fluid into a plurality of flat flow paths is accommodated in the measurement flow path housing portion 205 , and the upper open portion is sealed with a lid portion 209 .

[0120] A circular through-hole 206a is formed in the transmitter-receiver mounting portion 206 of the short side wall portion of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com