Cooling structure of rain-proof frequency conversion generator group

A technology for cooling structures and generator sets, which is applied to electric components, cooling/ventilation devices, electrical components, etc., can solve the problems of affecting the heat dissipation effect, small cross-section of the air duct, reducing the service life of the inverter, etc., to improve the assembly process. The effect of increasing the air duct cross section and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

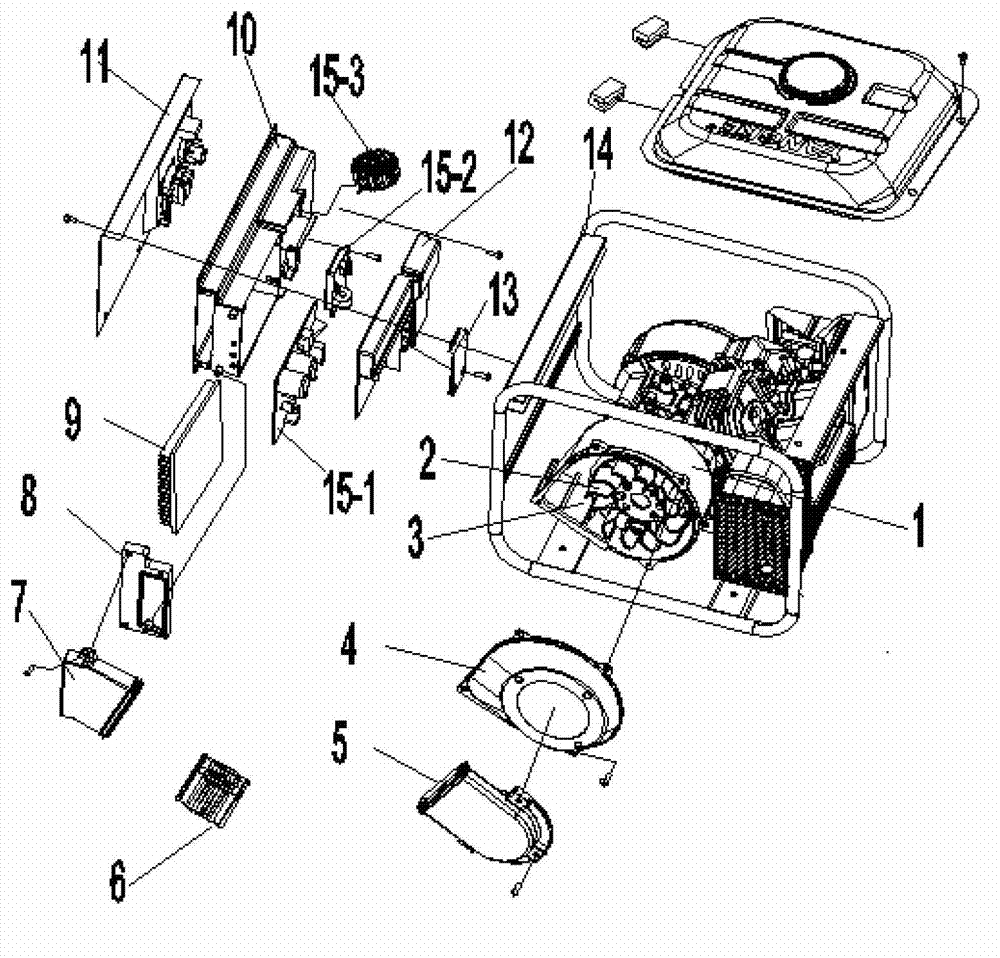

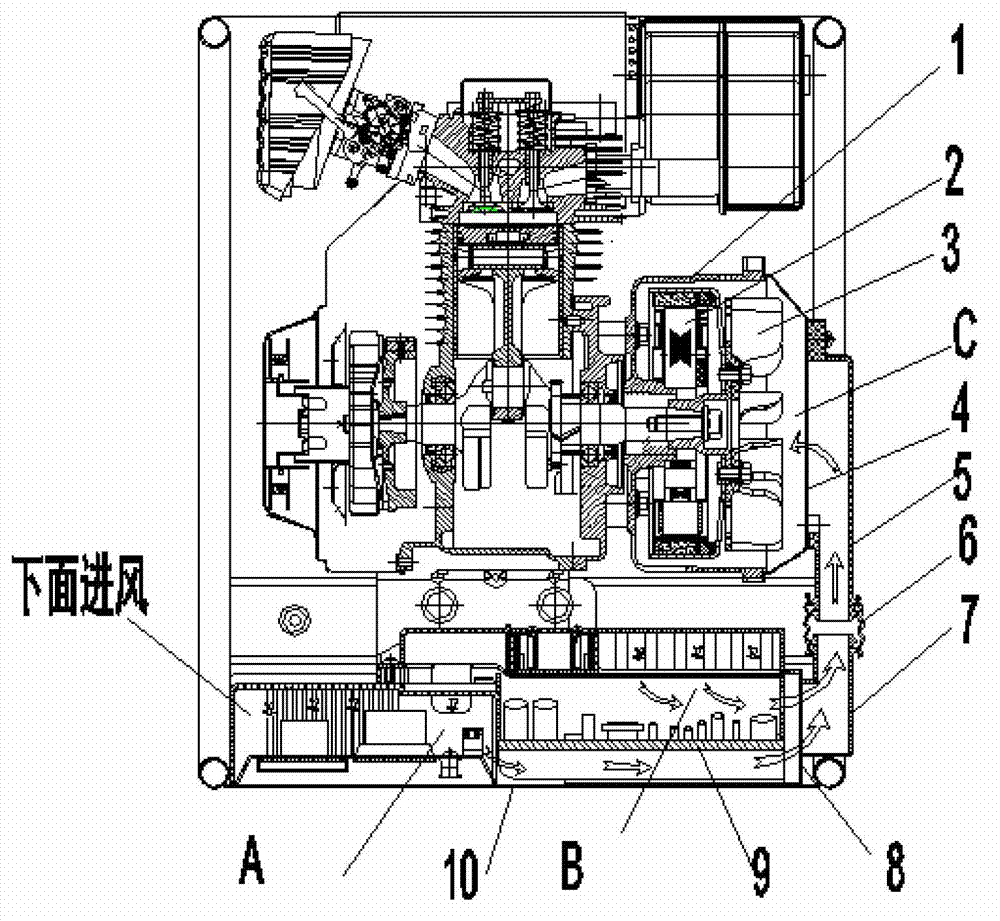

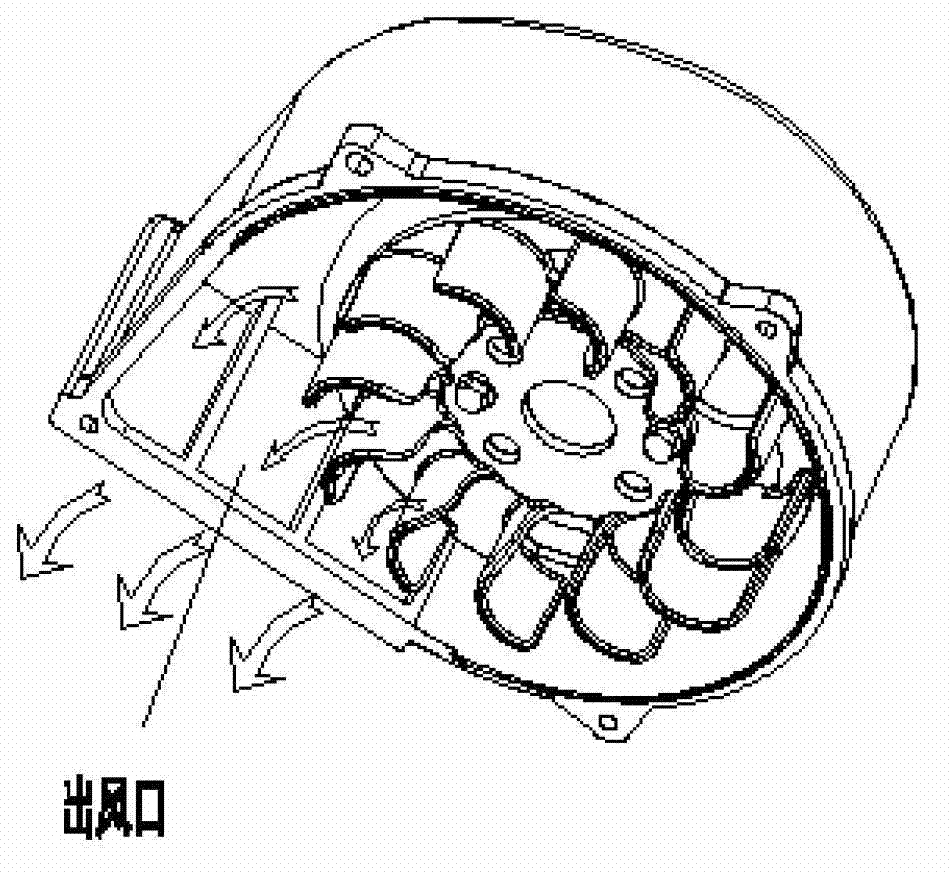

[0017] Depend on figure 1 , figure 2 , image 3 , Figure 4 It can be seen that the present invention includes: an installation box, an inverter controller, a control panel 11, a first hose 6, a turbine shell 1, a turbine cover 4, a generator 2, and wind blades 3; the installation box includes: an inverter Installation box 10, back cover 12, rainproof cover plate 13, connecting body 8 and inverter wind guide joint 7; Described installation box and control panel 11 are fixed on the frame 14; Described inverter controller comprises: Variable unit 15-1, electric regulator 15-2 and inductance 15-3; the inverter controller is fixed on the inverter installation box 10; The inverter installation box 10 is connected; the heat sink 9 and the control panel 11 form the first cooling and ventilation folder A; the rear cover 12 and the rainproof cover 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com