Stamping device system

A stamping device, loader technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of large, sliding accident product thickness, etc., to achieve the effect of suppressing uneven thickness and preventing sliding accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

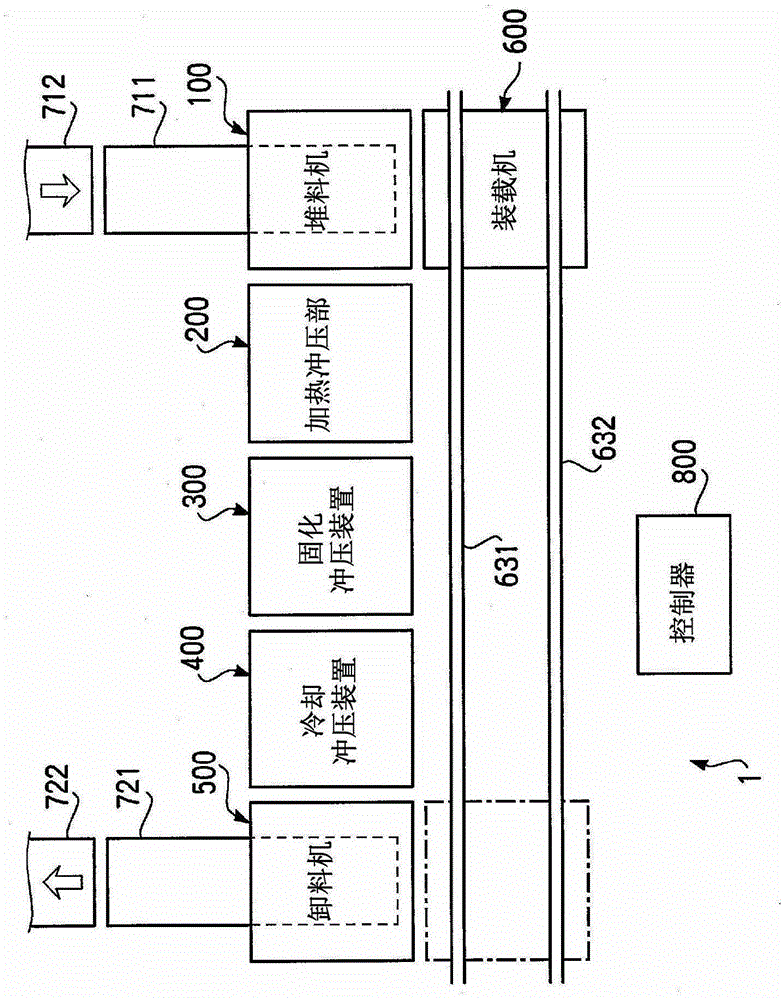

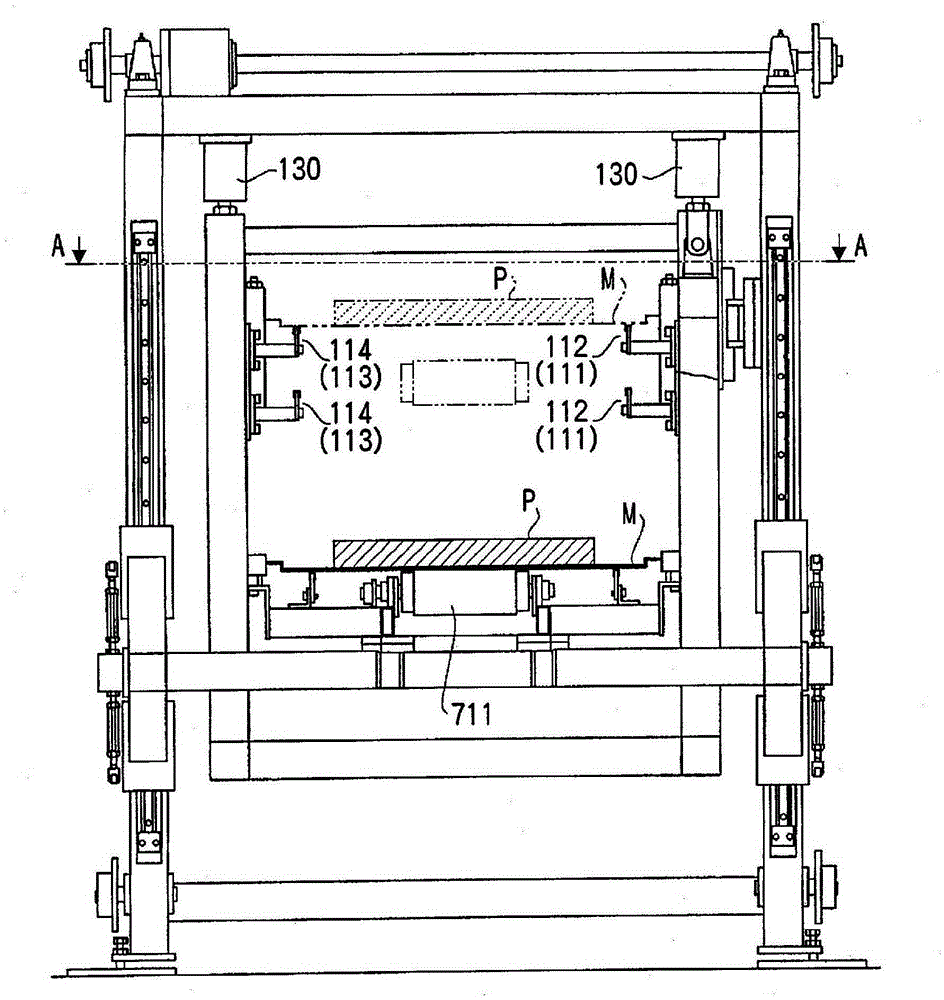

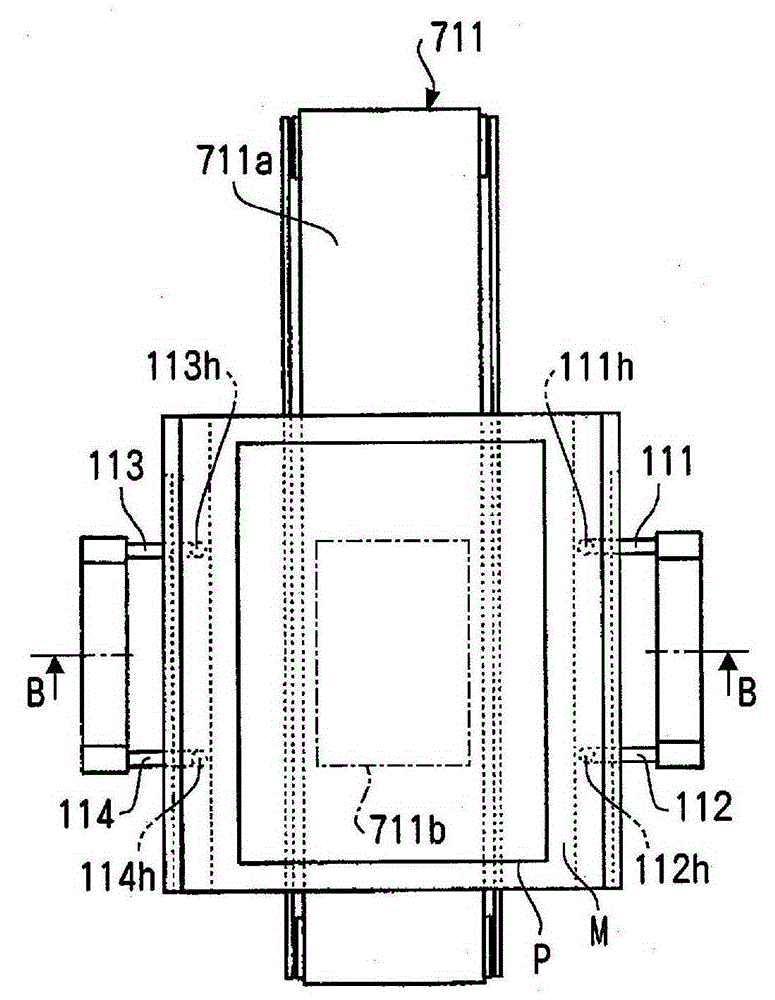

[0023] Hereinafter, embodiments of the present invention will be described in detail using the drawings. figure 1 It is a block diagram showing the whole of the press machine system 1 of this embodiment. The press device system 1 of the present embodiment includes: a stacker 100 for temporarily storing the workpiece before forming; a heating press unit 200 for heating and pressing the workpiece; and curing press (cure press) for the workpiece after heating and pressing The solidification stamping device 300; the cooling stamping device 400 for cooling and solidifying the workpiece after stamping; the unstacker (unstacker) 500 for temporarily storing the processed workpiece after cooling stamping; , the loader 600 for transferring the workpiece between the solidification press device 300 , the cooling press device 400 , and the unloader 500 . In addition, an assembly section (not shown) for producing a workpiece formed by alternately stacking a plurality of prepregs and copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com