Method and device for solution filming

A technology of solution film making and equipment, which is applied to flat products, coatings, household utensils, etc., can solve the problem of uneven thickness and achieve the effect of suppressing uneven thickness

Inactive Publication Date: 2014-07-16

FUJIFILM CORP

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

If the state where the belt end is partially in contact with the peripheral surface of the drive roller continues, the deformation of the side portion of the belt will increase, so the above-mentioned problem caused by uneven thickness is likely to occur.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0256] Hereinafter, in order to confirm the effects of the present invention, Experiments 1 to 8 were performed. The details of each experiment will be described using Experiment 1, and only the conditions different from Experiment 1 will be shown for Experiments 2 to 8.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Login to View More

Abstract

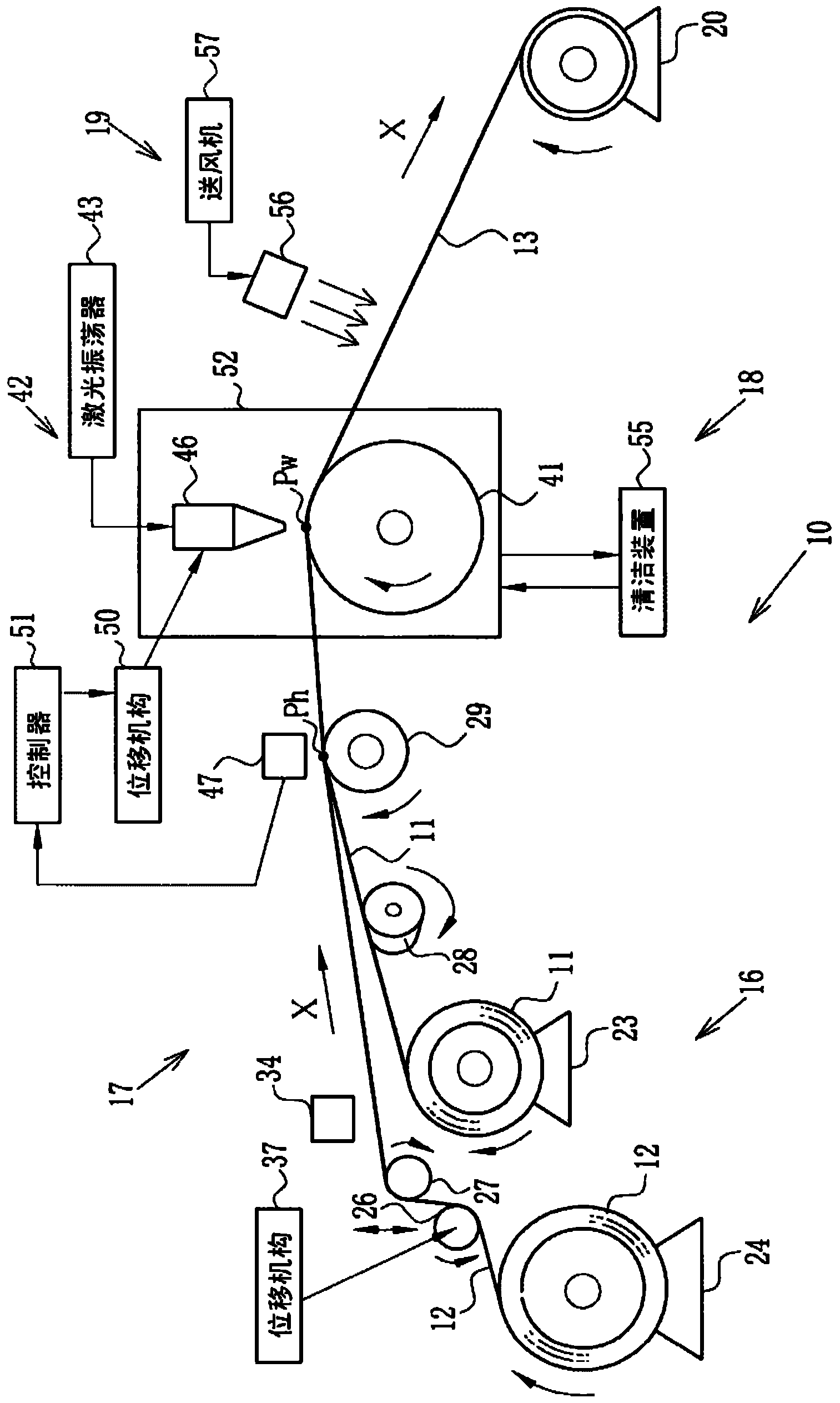

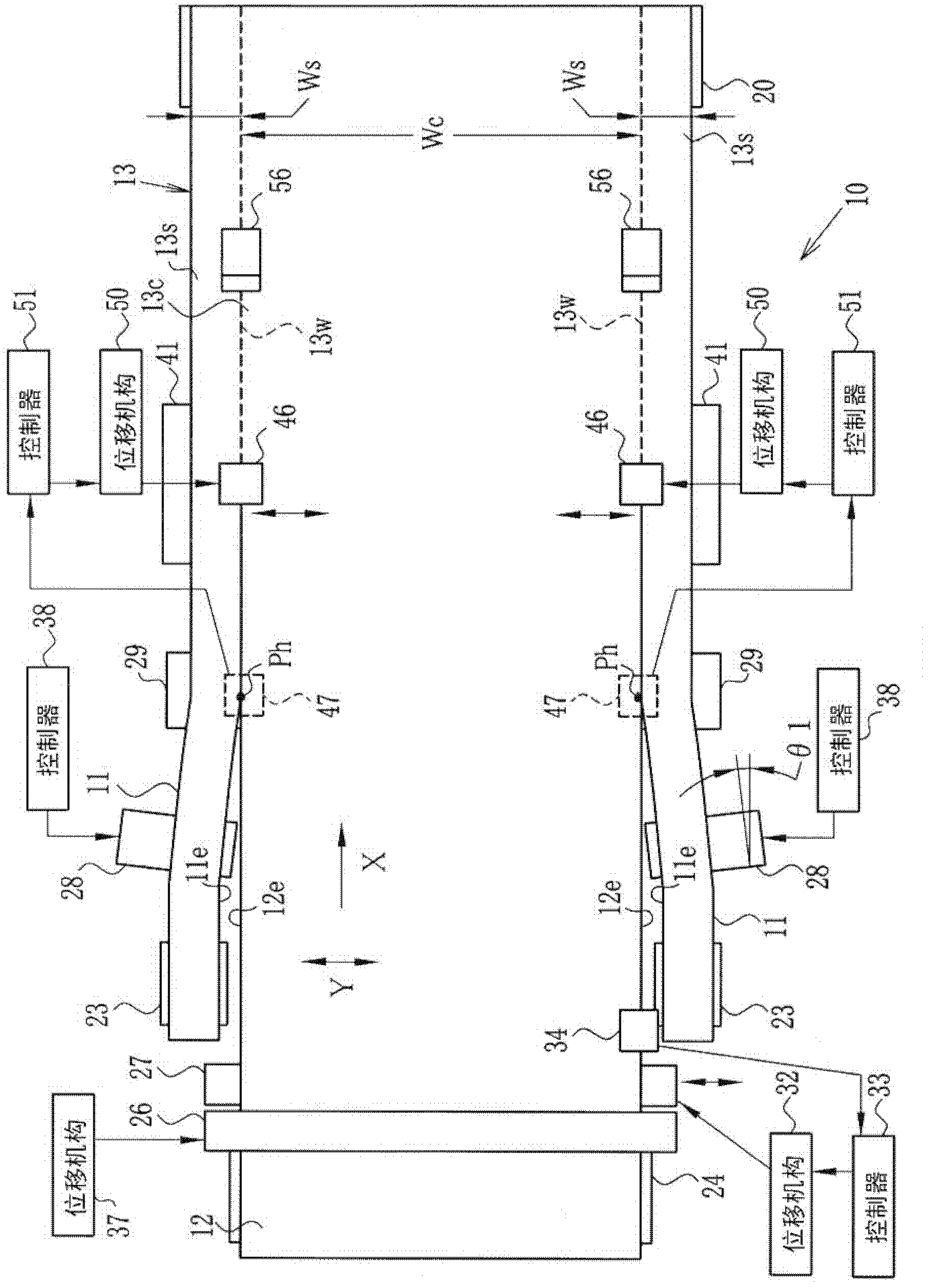

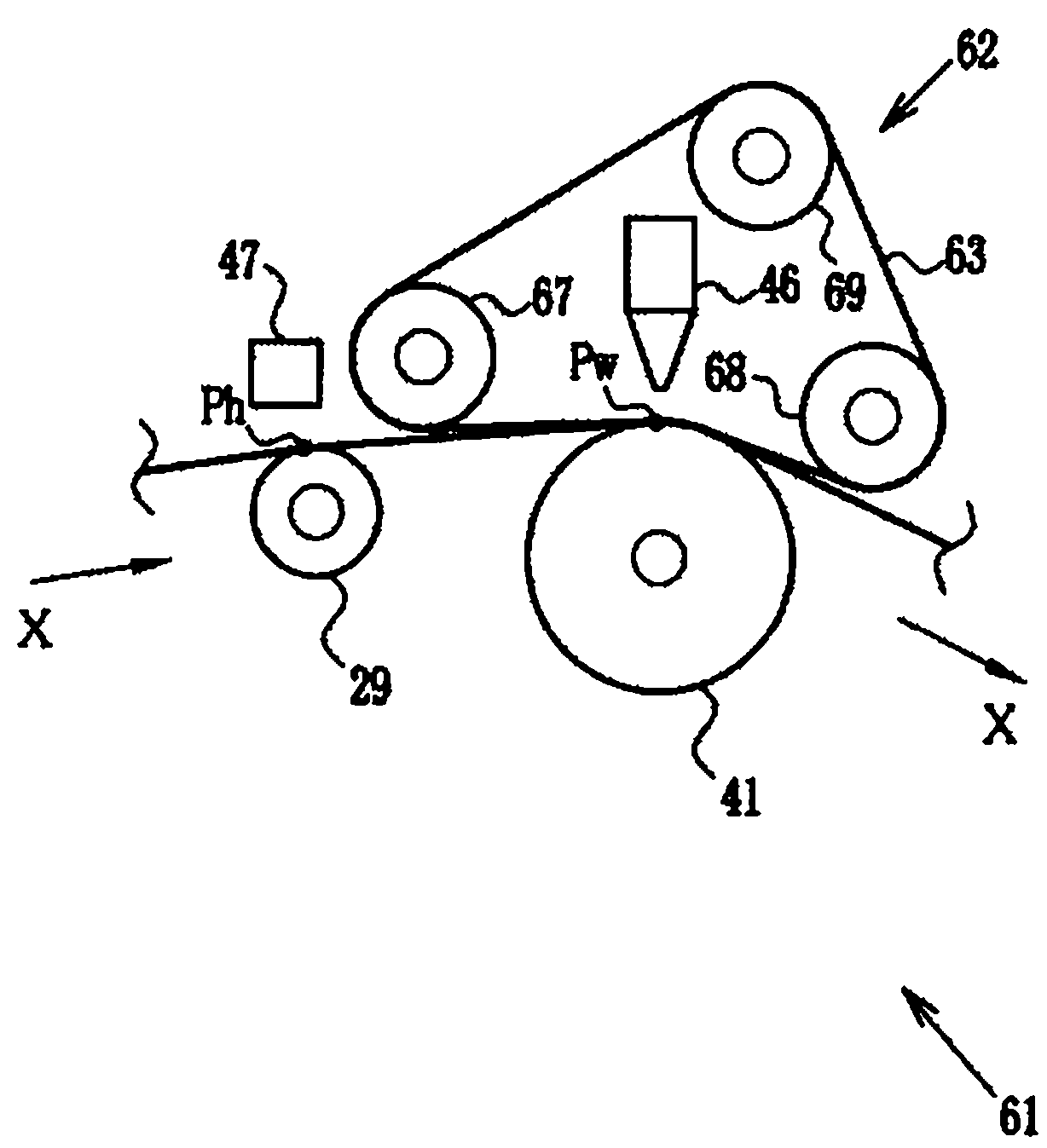

The invention provides a method and device for solution filming. A belt (91) moves toward the long-edge direction in a cycling manner via the rotation of a roller (131). A distance sensor (180) senses the space Cx with a belt (91). After a control portion (198) reads the space Cx from the distance sensor (180), the control portion (198) calculates the floating amount CL between the belt (91) and the roller (131) in the width direction from the read space Cx. The control portion (198) determines the stream in the width direction along the boundary position Pr of the district A1 according to the floating amount CL. The length of the outflux (131a) in the width direction is adjusted according to the boundary position Pr. The curtain coating die, adjusted by the length L0 of the outflux (131a), flows concentrated liquid toward the belt (91).

Description

technical field [0001] The invention relates to a solution film forming method and solution film forming equipment. Background technique [0002] Along with the enlargement of the screen of a liquid crystal display (LCD), the optical film used for an LCD is also required to enlarge the area. After the optical film is manufactured into a long shape, it is cut into a predetermined size according to the size of the LCD. Therefore, in order to manufacture an optical film having a larger area, it is necessary to manufacture an elongated optical film having a wider width than conventional ones. [0003] As a typical production method of elongated optical films, there is a solution film-forming method in a continuous system. As is well known, in a continuous method of solution film production, a dope in which a polymer is dissolved in a solvent is cast on a moving casting support, and a casting film composed of the dope is formed on the casting support. In this method, a film is...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08J5/18

CPCB29C41/26B29C41/28B29C41/46B29C41/52B29D11/00788B29L2007/00B29L2011/00

Inventor 新井利直山崎英数

Owner FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com