Cast-weld mold for storage battery electrode plate

A technology for casting and welding molds and batteries, applied in the field of casting and welding of metal plates of batteries or the like, can solve problems such as intensification of gaps or cracks, separation of tabs and busbars, and scrapping of batteries, so as to reduce structural gaps, The effect of extending life and optimizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

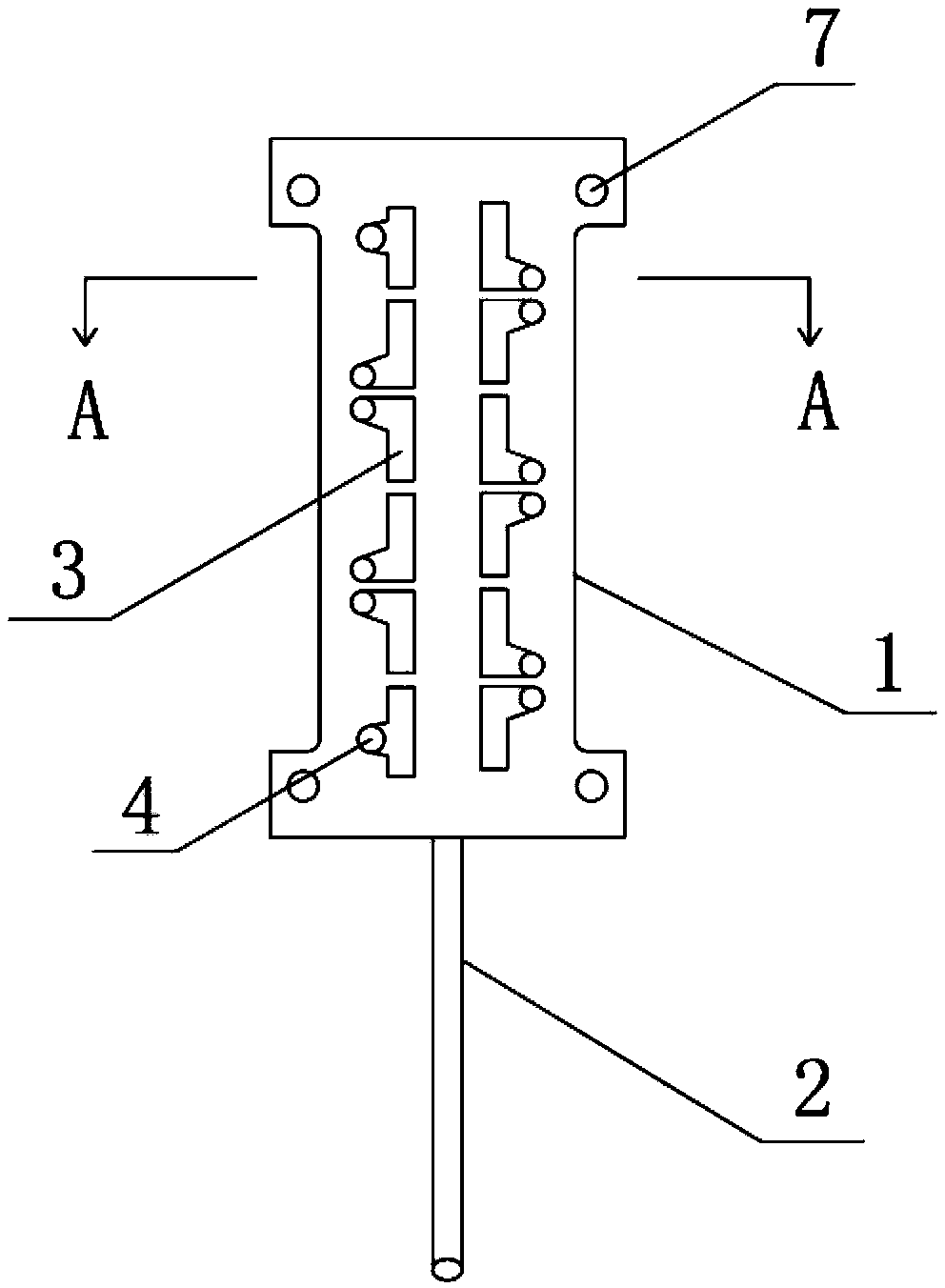

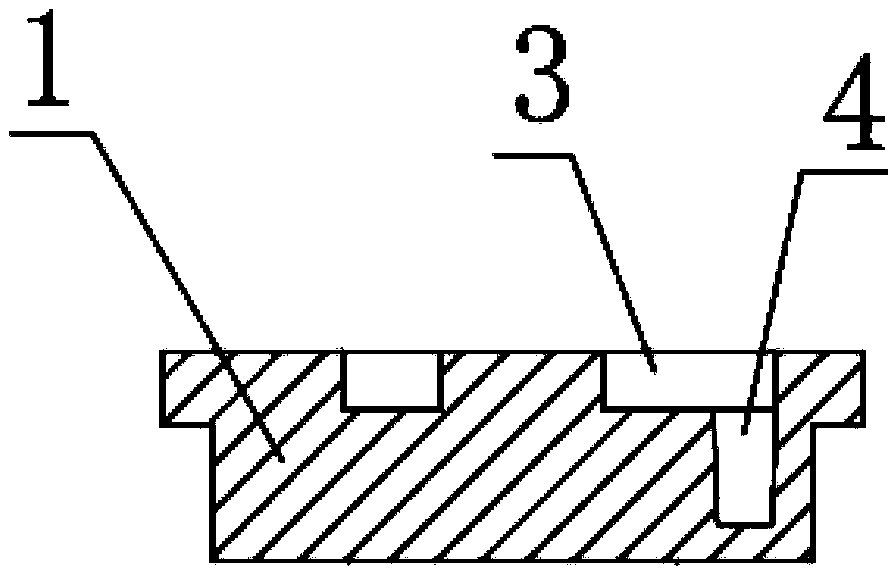

[0021] Such as Figure 4~6 As shown, a battery plate casting and welding mold, its body 1 includes two separate positive electrode templates 11 and negative electrode templates 12 .

[0022] Both the positive template 11 and the negative template 12 are provided with handles 2, and the positive template 11 is provided with 6 confluence grooves 3 and 6 penetrating hollow parts 5. The confluence groove 3 is provided with pole pits 4, and the hollow parts 5 are rectangular holes. Confluence grooves 3 and hollow parts 5 are alternately arranged horizontally, and confluence grooves 3 and hollow parts 5 are alternately arranged vertically. One confluence groove 3 and one hollow part 5 are arranged horizontally. Three confluence grooves 3 and three hollow parts 5 are respectively provided, and positioning holes 7 are provided around the positive electrode template 11 .

[0023] The negative electrode template 12 is provided with 6 confluence grooves 3 and 6 hollowed-out parts 5, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com