Special four-station machine tool for jackscrew holes of worms

A special-purpose machine tool and top screw hole technology, which is applied to metal processing machinery parts, positioning devices, manufacturing tools, etc., can solve the problems of low qualification rate and low labor efficiency, and achieve the effects of improving efficiency, reducing labor costs, and concentrating processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

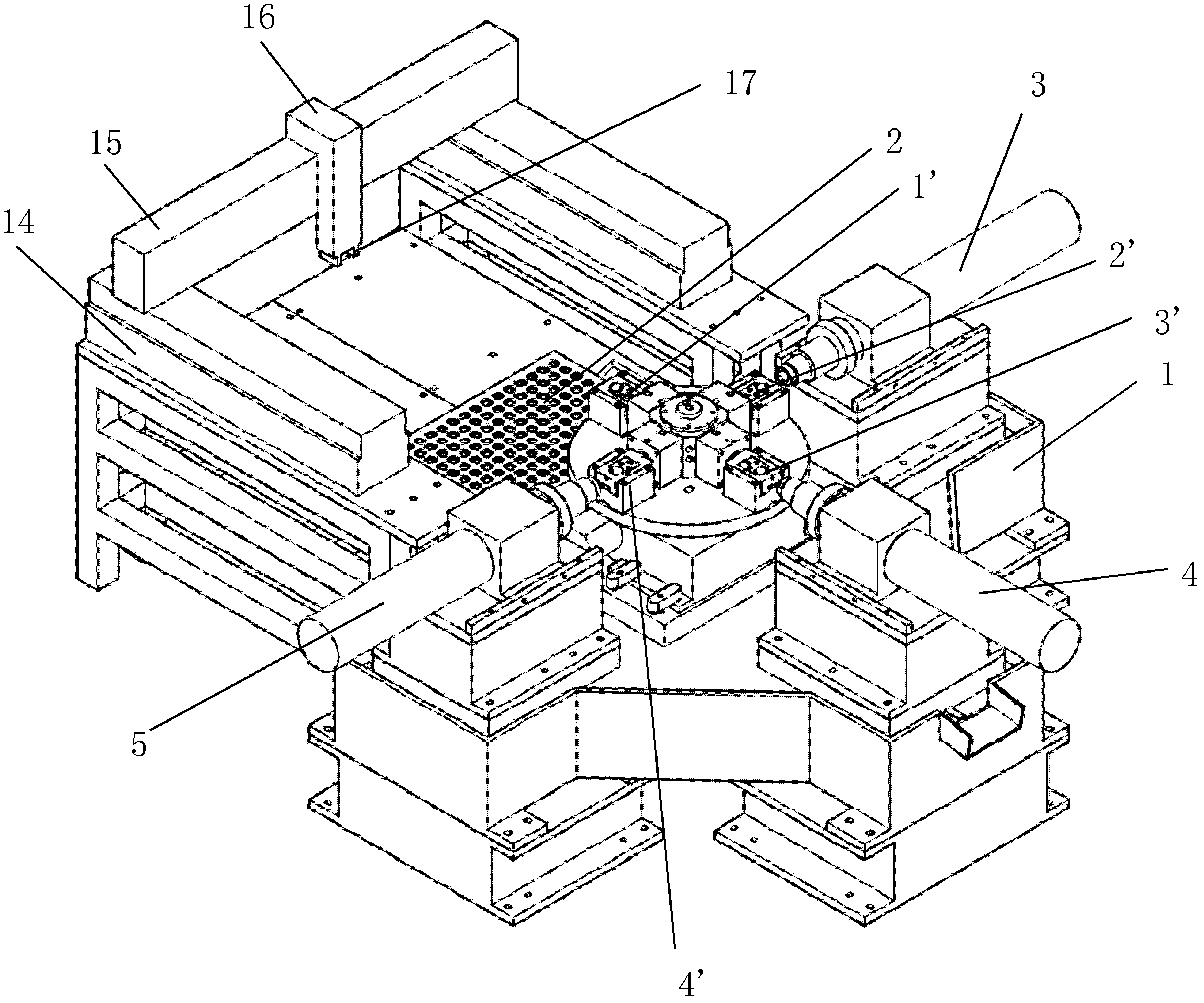

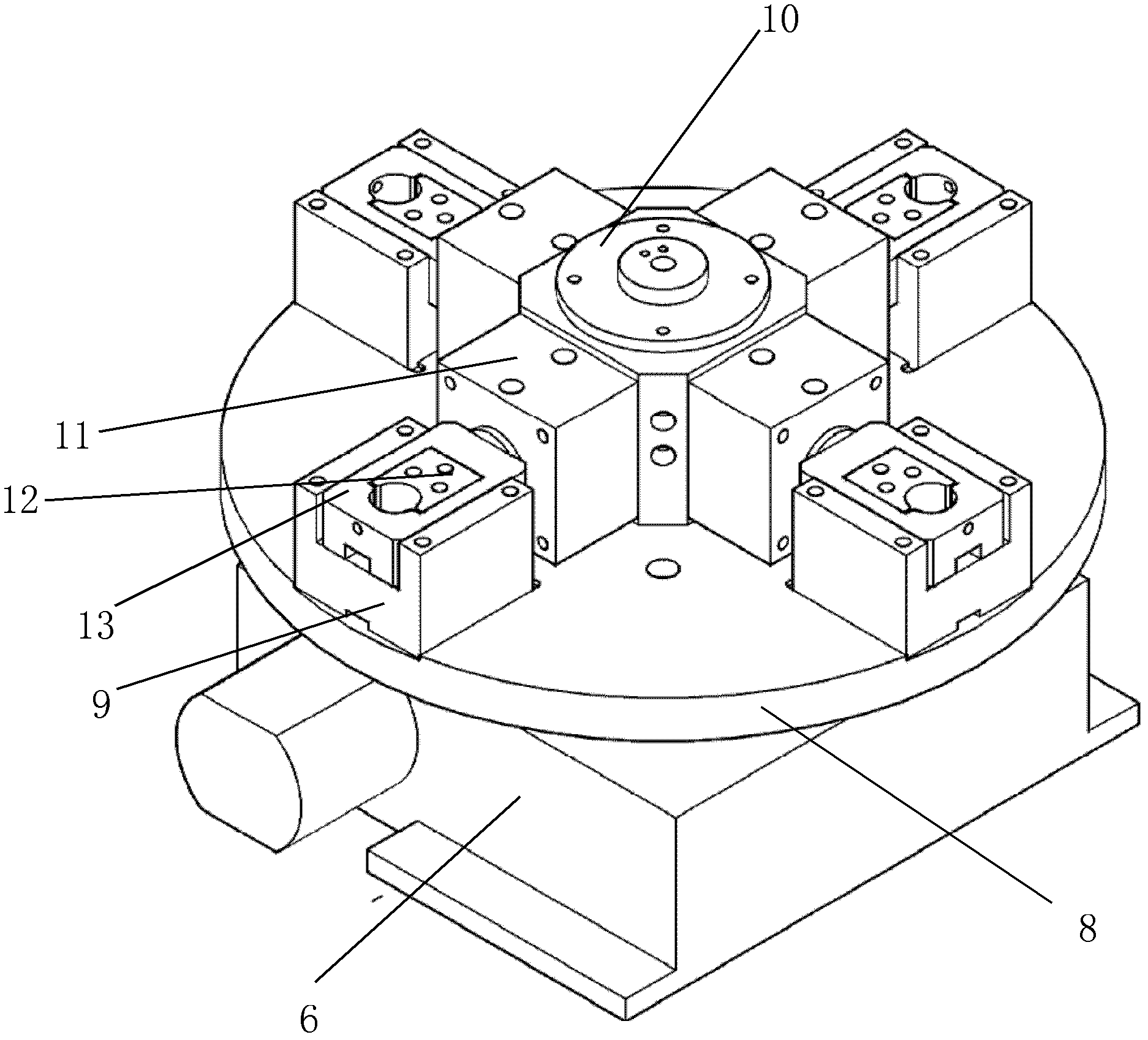

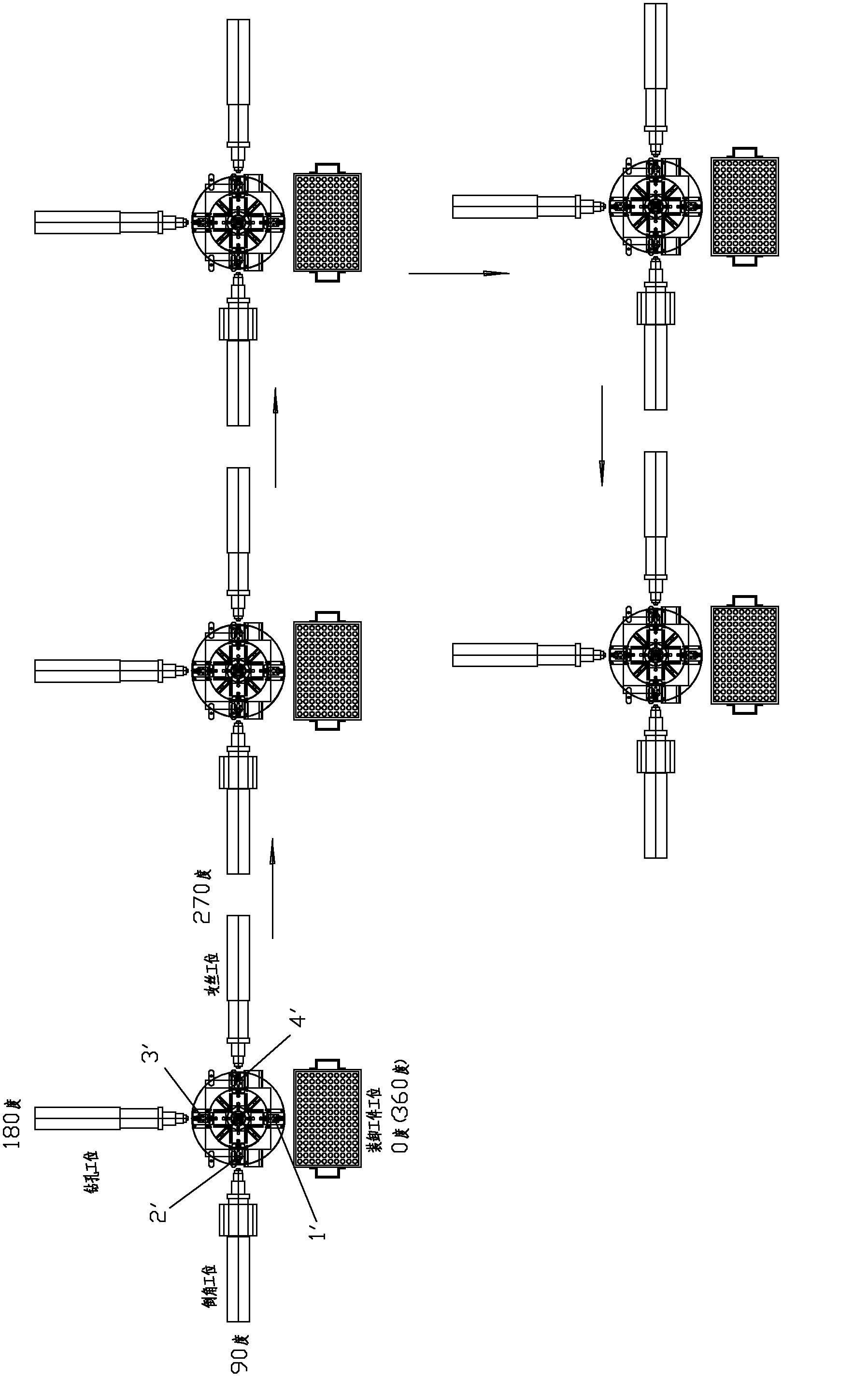

[0013] Below in conjunction with the preferred embodiments, the specific implementation methods provided according to the present invention are described in detail as follows: See the accompanying drawings for details, a four-station special machine tool for the top screw hole of a worm, including a bed 1, a material tray 2, a chamfering power Head 3, drilling power head 4, threading power head 5, hydraulic turntable 6, fixture 7, a hydraulic turntable is affixed to the center of the bed worktable, and an inverted rotator is fixed symmetrically along the transverse axis of the hydraulic turntable on the bed worktable. Angle power head, tapping power head, chamfering power head and tapping power head are fixed with drilling power head radially along the hydraulic turntable, and the rotary station of the hydraulic turntable is provided with a fixture for installing workpieces. A disc 8 is fixed on the hydraulic turntable, and four clamps 1'-4' are fixed on the disc symmetrically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com