Winder and method for winding wire on winder

一种缠绕电线、绕线器的技术,应用在线圈、电路、线圈制造等方向,能够解决绕线方法费力、耗时、无法精确地控制末端产品品质等问题,达到减少工作时间、简化步骤的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The preferred embodiments of the present invention are described hereby in conjunction with the accompanying drawings.

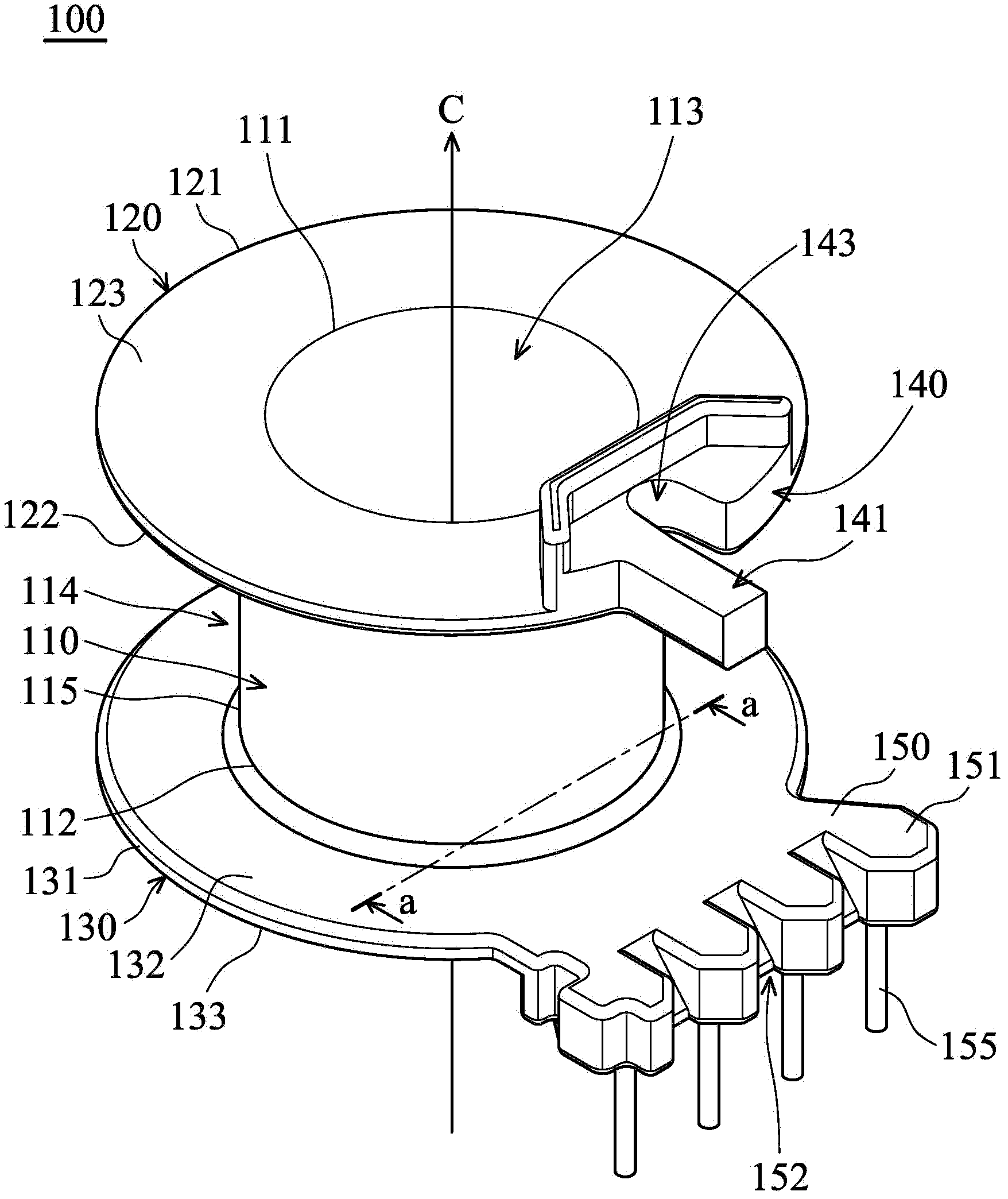

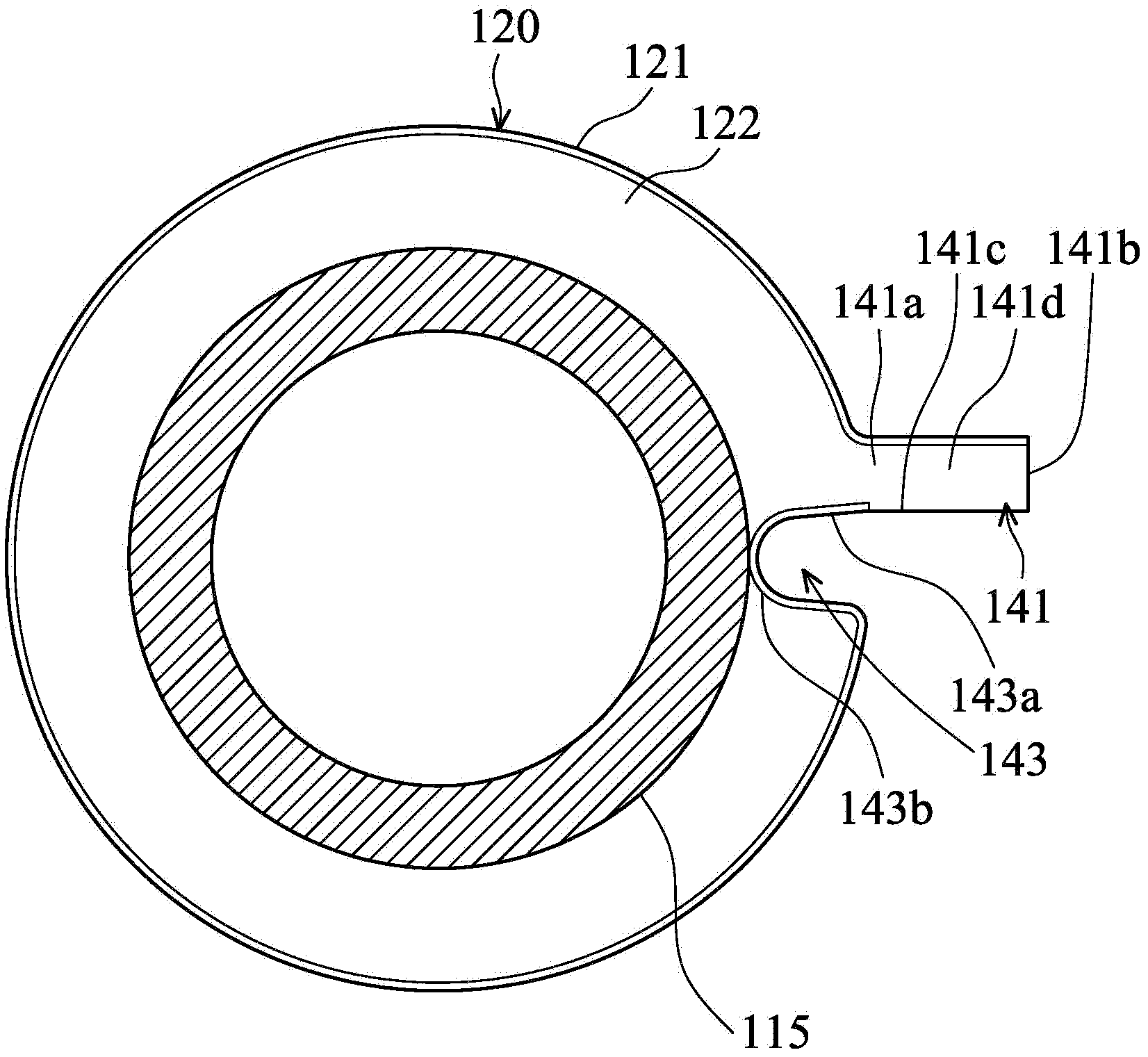

[0062] Please refer to Figures 2A and 2B, where Figure 2B show Figure 2A The cross-sectional view viewed from the a-a section line towards the axis C. The cable winder 100 according to the first embodiment of the present invention includes a body 110 , a first baffle 120 , a second baffle 130 , a guide 140 , an extension 150 and a plurality of conductive pins 155 .

[0063] The body 110 is a hollow cylinder with two ends 111 , 112 and a channel 113 . The body 110 extends on an axis C, and two end portions 111 , 112 are defined on two sides of the body 110 on the axis C, respectively.

[0064] The first baffle 120 circumferentially surrounds the end portion 111 of the body 110 and extends radially. The second baffle 130 circumferentially surrounds the end portion 112 of the body 110 and extends radially. The peripheral edges 121 and 131 of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com