Method for enhancing durability of pier column under freeze thawing or chlorine salt erosion environment

A technology of durability and pier column, which is applied to the pier column of concrete cast-in-place construction, improves the durability of the pier column under the environment of freezing and thawing or chloride salt erosion, and can solve the loss of the concrete protection function of the pier column and the failure of the performance to reach the design goal. , organic coating peeling and other problems, to achieve the effect of shortening offshore operation time, significant technical and economic benefits, and saving maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

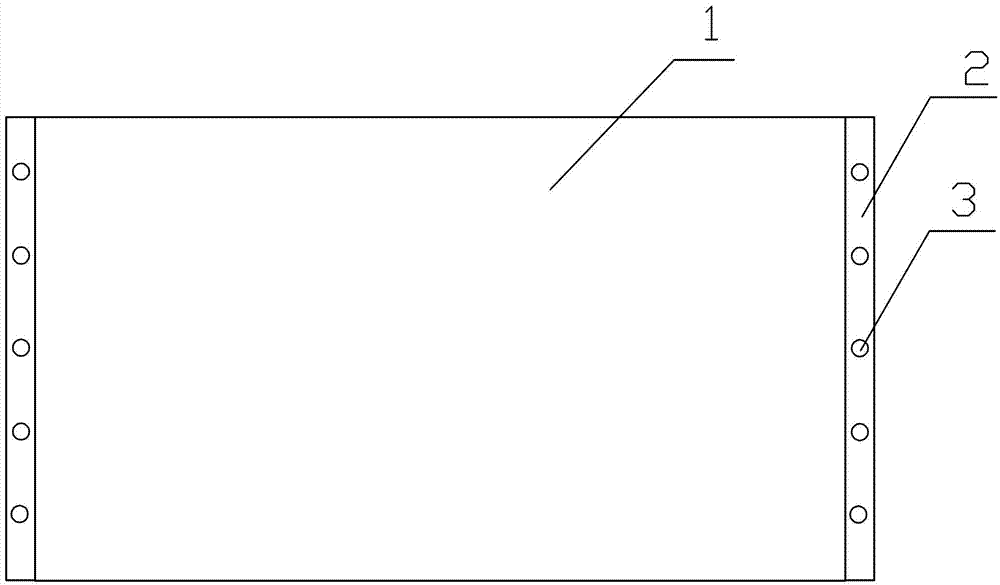

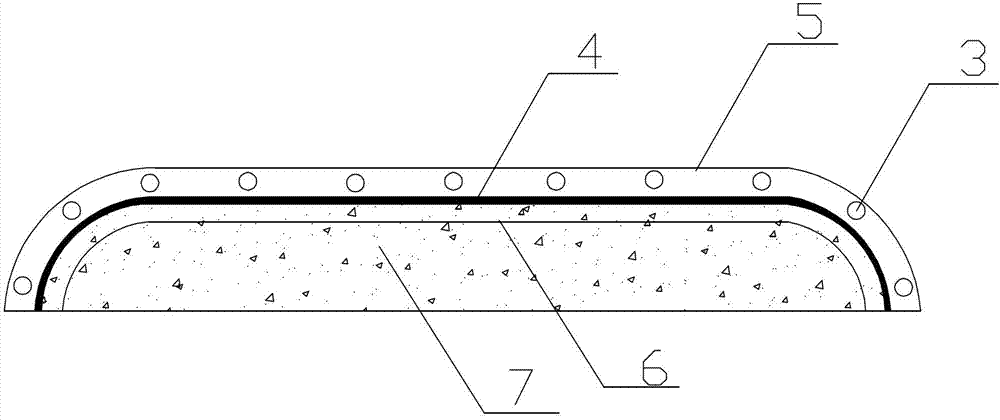

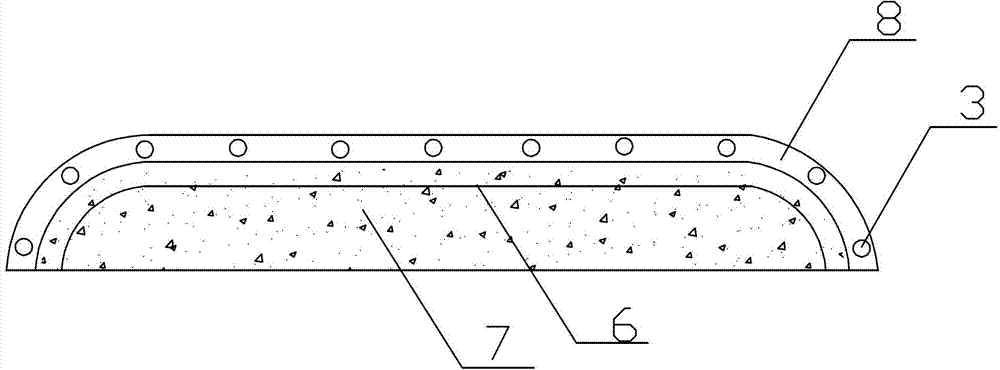

[0024] combine figure 1 , figure 2 and image 3 , a formwork for improving the durability of piers in a freeze-thaw or chlorine salt erosion environment, including pier formwork 1, 8 and a sheath 4 with high freeze-thaw durability and / or chlorine salt erosion resistance; preferably, the above-mentioned sheath An energy-absorbing material layer can be pasted on the inner side of the cover, and the above-mentioned energy-absorbing material layer can be a plastic foam layer. The above-mentioned sheath is fixed on the inner wall of the pier formwork, and adopts a detachable connection structure with the pier formwork. When the concrete pouring of the pier column is completed and the form removal condition is met, the sheath has been combined with the pier column concrete 7, and the pier column formwork is removed to separate the pier column formwork from the sheath, and the sheath is left on the surface of the pier column.

[0025] A method for improving the durability of pier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com