Construction method of precipitation well

A construction method and technology for dewatering wells, which are applied in infrastructure engineering, construction, sheet pile walls, etc., can solve the problems of high environmental protection pressure, scrapped wells, and difficult to flush, so as to reduce labor costs, reduce auxiliary workers, and prevent sludge. influx effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

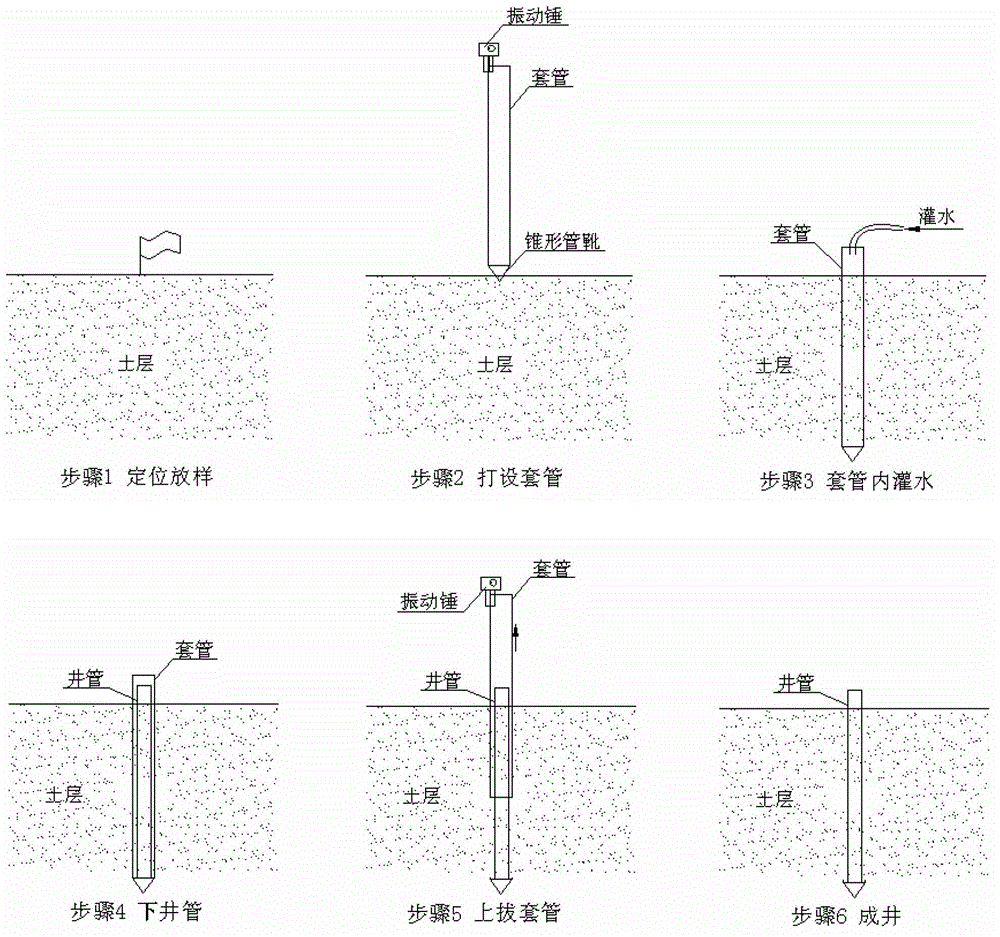

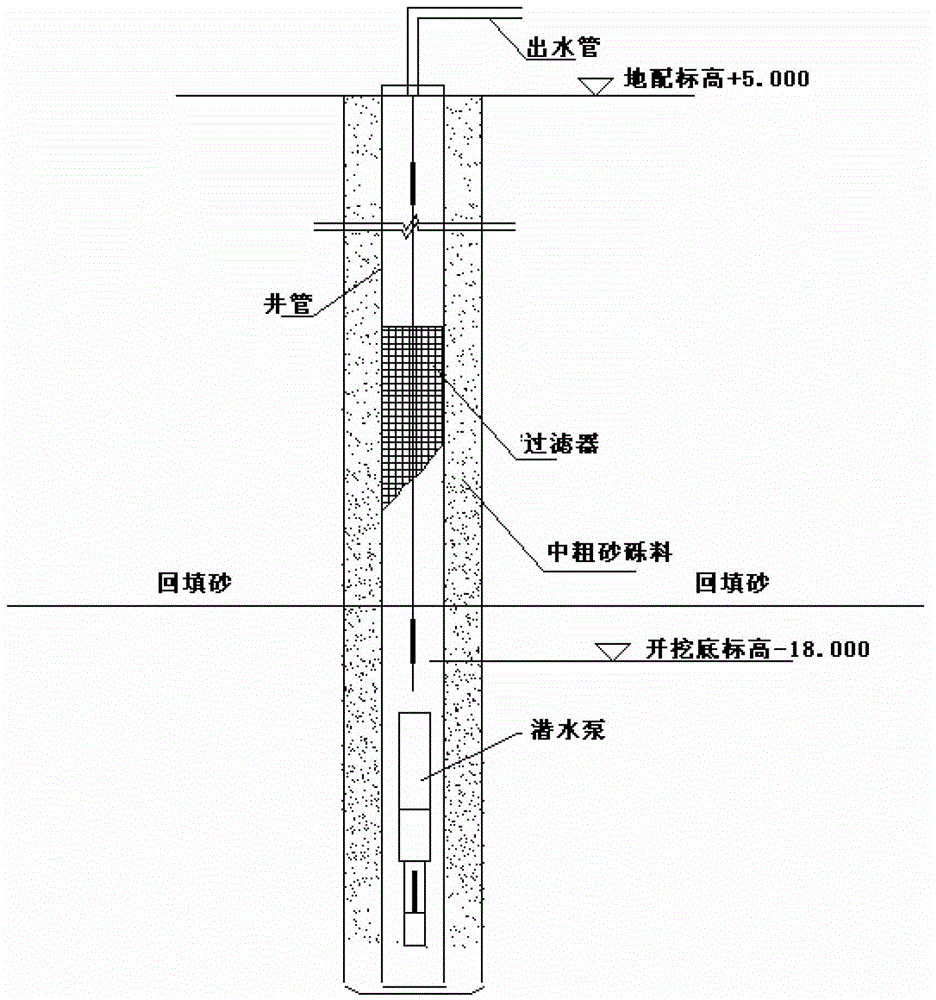

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

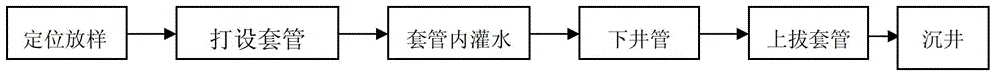

[0032] refer to figure 1 and figure 2 , a construction method of a dewatering well, comprising the following steps:

[0033] (1) Positioning and stakeout

[0034] Use the GPS positioning system or other measurement and positioning methods combined with the stakeout coordinates of the design drawings to stake out and insert flags for identification, and then place tapered pipe boots on the corresponding positions of the sample points;

[0035] (2) Setting up casing

[0036] Use a crane to lift the hydraulic vibratory hammer, the vibratory hammer clamps the casing, inserts the casing into the conical pipe shoe on the stakeout point, and is fixedly connected by the steel hoop of the conical pipe shoe, and then opens the vibratory hammer to conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com