Fan rotating speed control circuit

A technology for controlling circuit and fan speed, applied in pump control, non-variable-capacity pump, machine/engine, etc., can solve the problems of large volume, users changing the rotor speed, and the inability of a single drive circuit to meet the wind speed, etc. Design streamlined effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, and are described in detail as follows:

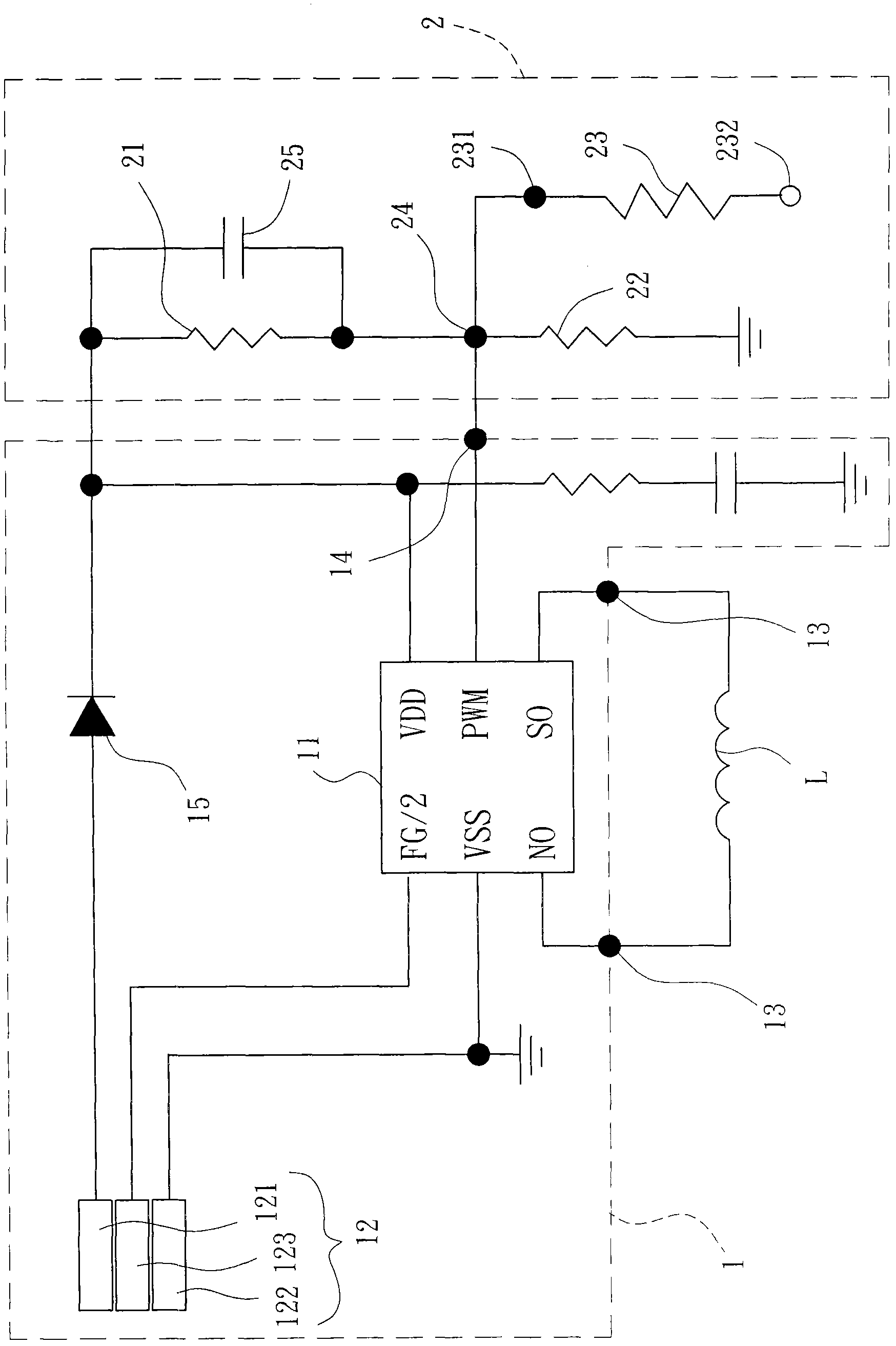

[0038] Please refer to figure 2 As shown, it shows the first embodiment of the fan speed control circuit of the present invention, and the fan speed control circuit is used to connect and control the driving current in the stator winding L of a fan motor to drive the fan motor to run. The fan speed control circuit includes a speed control drive unit 1 and a speed control unit 2, wherein the speed control drive unit 1 is connected to the stator winding L, and the speed control unit 2 is connected to the speed control drive unit 1, and the speed control The unit 2 can output a speed regulation voltage for the speed control drive unit 1 to output the driving current corresponding to the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap