Low-noise regulating valve

A control valve and low-noise technology, applied in the field of control valves, can solve the problems of high noise, high cost of noise control, poor consideration of its own structure and flow field characteristics, etc., and achieve the effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

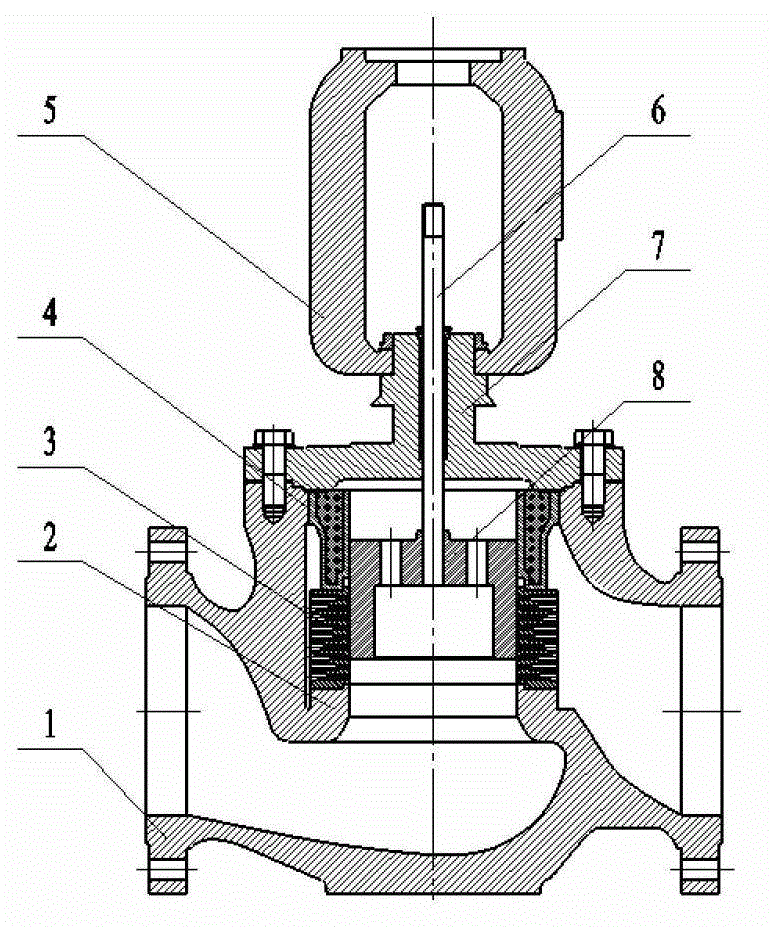

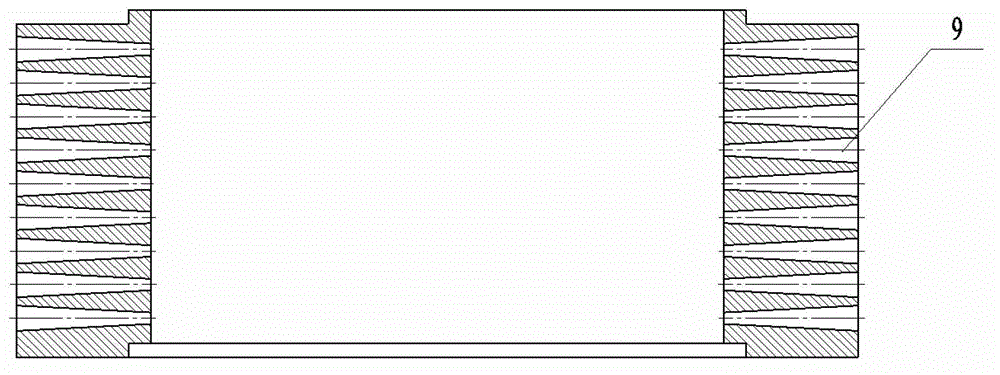

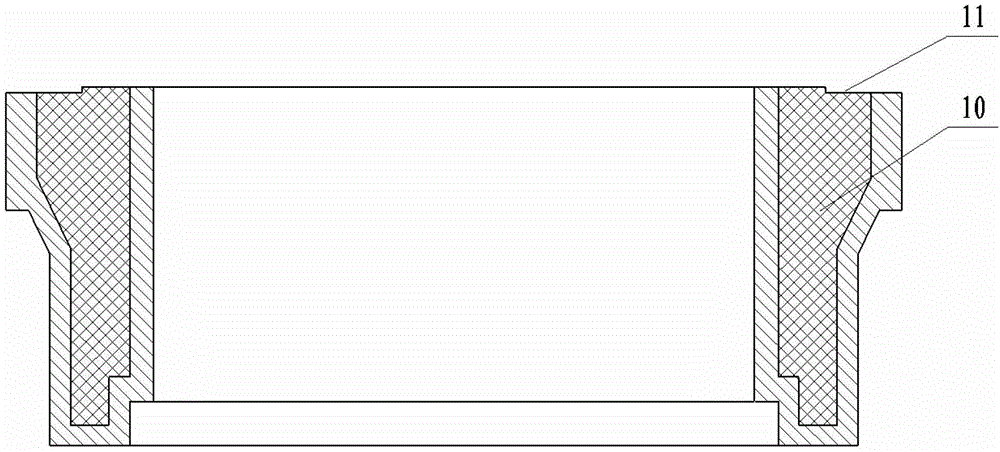

[0021] Such as Figure 1-Figure 4 As shown, the low-noise regulating valve of the present invention is mainly composed of a valve body 1, an end cover 7, a bracket 5, a valve stem 6 and a valve core 8, and a sleeve valve core 4 is installed in the valve body 1, so that the valve core 8 moves along the valve stem. 6 moves axially to reduce the influence of the fluid on the radial force of the spool 8. A sleeve 3 is installed on the valve seat 2 in the valve body 1, and is fixed by the sleeve valve core 4. There are several tapered holes 9 in the sleeve 3, so that the fluid flows through the tapered holes 9 in the sleeve 3 to the control valve. throttle.

[0022] When cleaning and replacing the sleeve valve core 4 and the sleeve 3 of the above-mentioned low-noise regulating valve, it is only necessary to open the end cover 7, first remove the sleeve valve core 4, and then take out the sleeve 3.

[0023] The present invention controls the noise of the regulating valve at the or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com