Residual gas recovery system of gas station compressor

A recovery system and compressor technology, applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of enterprise loss, environmental impact, waste, etc., and achieve the effect of avoiding environmental damage and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments of the description:

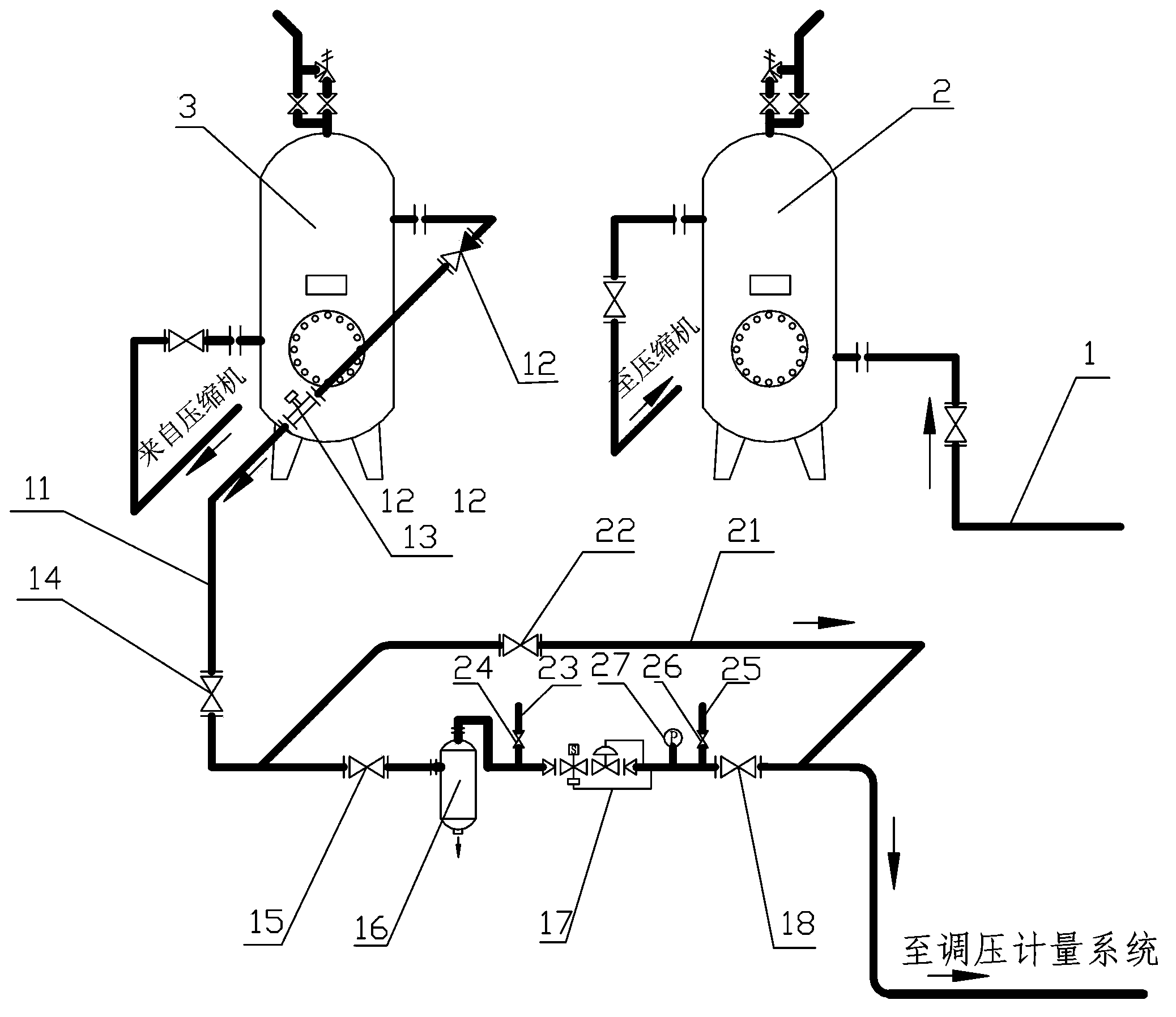

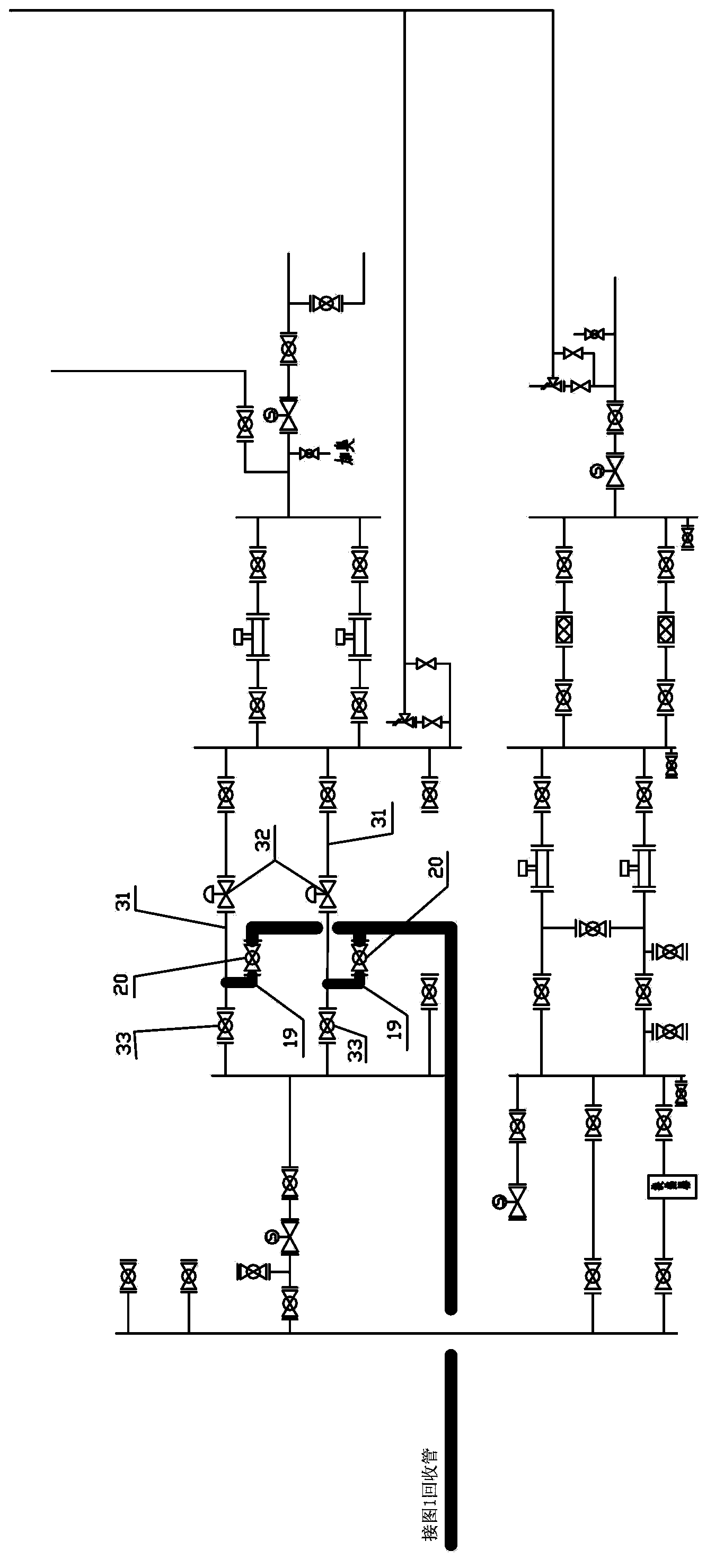

[0013] It includes high-pressure intake pipe 1, buffer tank 2, compressor, recovery tank 4, high-pressure intake pipe connected to the buffer tank, the buffer tank, compressor, and recovery tank are connected in sequence, and it also includes residual gas recovery connected to the pressure regulating metering system system. The main body of the residual gas recovery system includes a recovery pipe 11, on which a check valve 12, a flow meter 13, a first ball valve 14, a second ball valve 15, a gas-liquid separator 16, and a pressure regulating valve are sequentially arranged along the gas flow direction. Voltage stabilizer 17, third ball valve 18; the main function of the gas-liquid separator is to effectively separate the oil in the residual gas of the compressor, to ensure the purity of the recovered residual gas, wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com