Array substrate and display device

An array substrate and substrate technology, applied in optics, instruments, electrical components, etc., can solve problems such as the average LCD brightness difference, and achieve the effect of reducing chromatic aberration and brightness difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

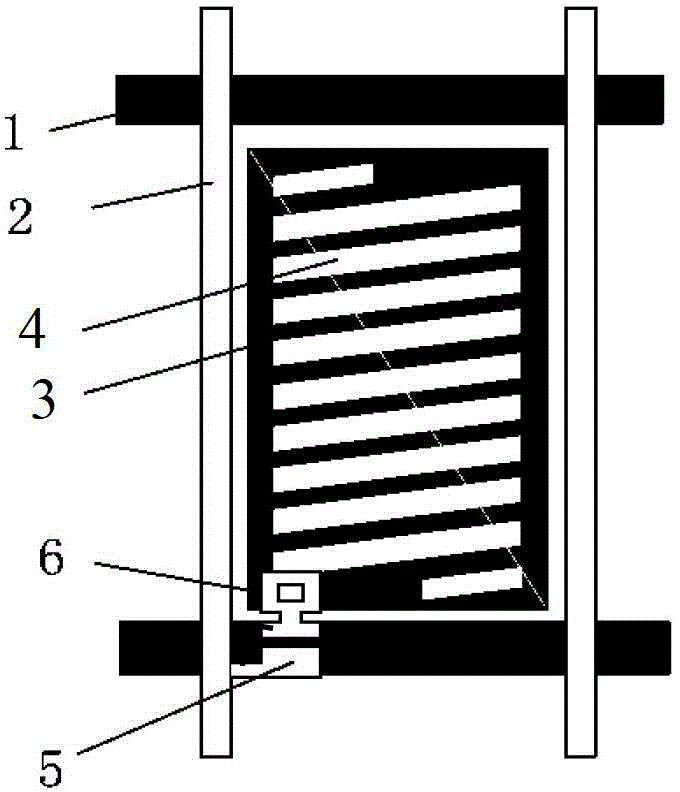

[0038] The array substrate structure of this embodiment is as follows Figure 5 As shown, it includes: a substrate, several gate lines 1 formed on the substrate, data lines 2 and pixel units. The pixel unit is driven by the same gate line 1 and the same data line 2, and the pixel unit includes: a thin film transistor structure and two display areas. The thin film transistor structure simultaneously drives the pixel electrodes in the two display areas, and makes voltages applied to the pixel electrodes in the two display areas different.

[0039] In this embodiment, the two display areas are respectively located on both sides of the gate line 1 driving the pixel unit.

[0040] In this embodiment, the thin film transistor structure is a composite thin film transistor structure, including: a gate (not shown in the figure), a source 5, and two drains 6, and there are respectively formed between the source 5 and the two drains 6 A source-drain channel. The gate is located on the...

Embodiment 2

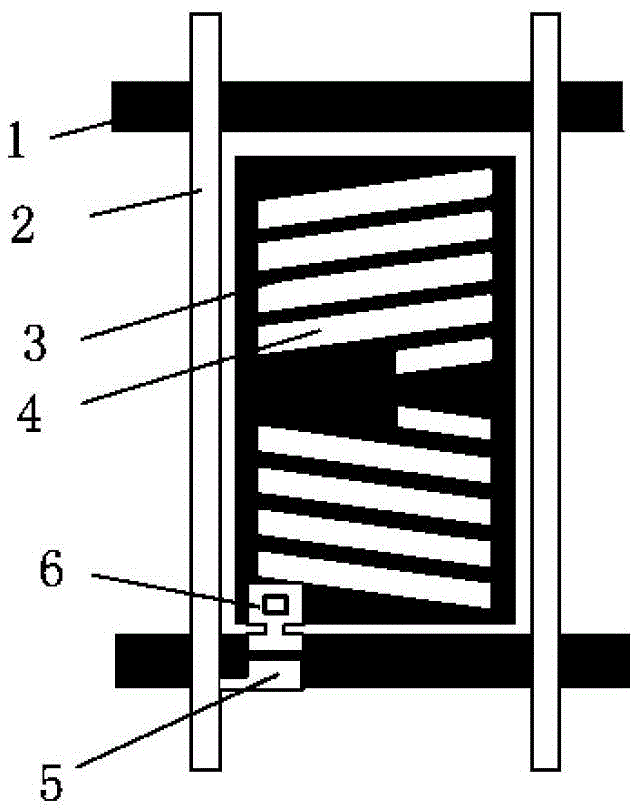

[0048] The array substrate of this embodiment is such as Figure 7 As shown, the structure of the array substrate in Embodiment 1 is basically the same. The difference is that in this embodiment, two independent thin film transistors (one gate, one source, and one drain) are used instead of the composite thin film transistor with common source and double drain. The gates of the two thin film transistors are located on the gate line 1 or connected to the gate line 1, the source electrodes 5 are connected to the data line 2, and the drain electrodes 6 are connected to the pixel electrodes 3 in the two display areas respectively, and the respective electrodes of the two thin film transistors The source-drain channels formed between the source 5 and the drain 6 have different channel widths.

[0049] Wherein, the channel widths of the respective source and drain channels of the two thin film transistors range from 20 to 30 um.

[0050] The rest of the structure is the same as th...

Embodiment 3

[0056] This embodiment also provides a display device, including the array substrate in any one of the above embodiments. The display device may be any product or component with a display function such as a liquid crystal panel, a liquid crystal TV, a liquid crystal display, a digital photo frame, a mobile phone, and a tablet computer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com