Finger board

A finger-pressing plate and pressing-plate technology, which is applied to the finger-pressing plate field of a fingerprint identification device, can solve problems such as difficulty in assembling light-emitting elements, and achieve the effects of improving the fingerprint identification rate, reducing the thickness and simplifying the assembly process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

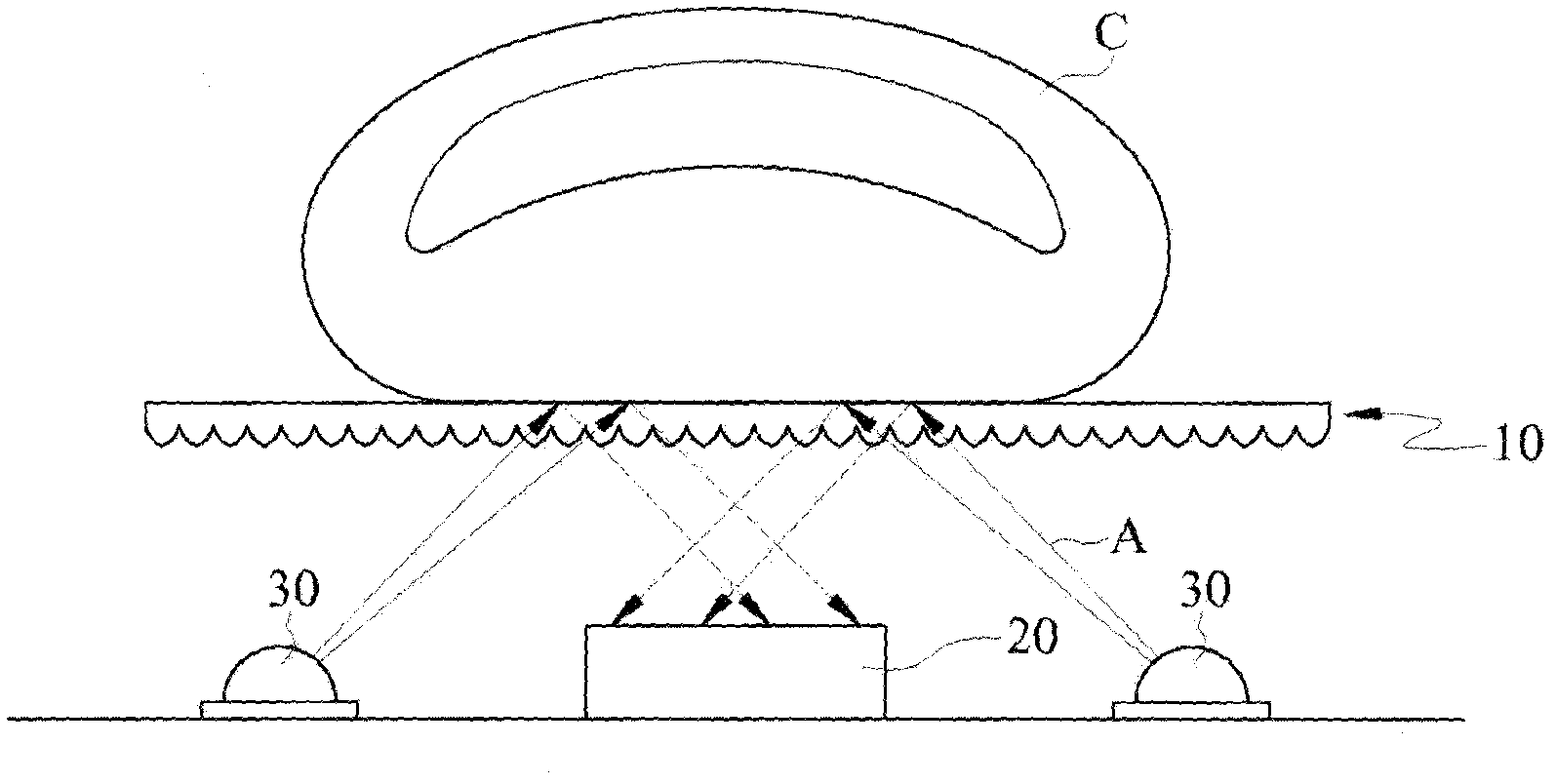

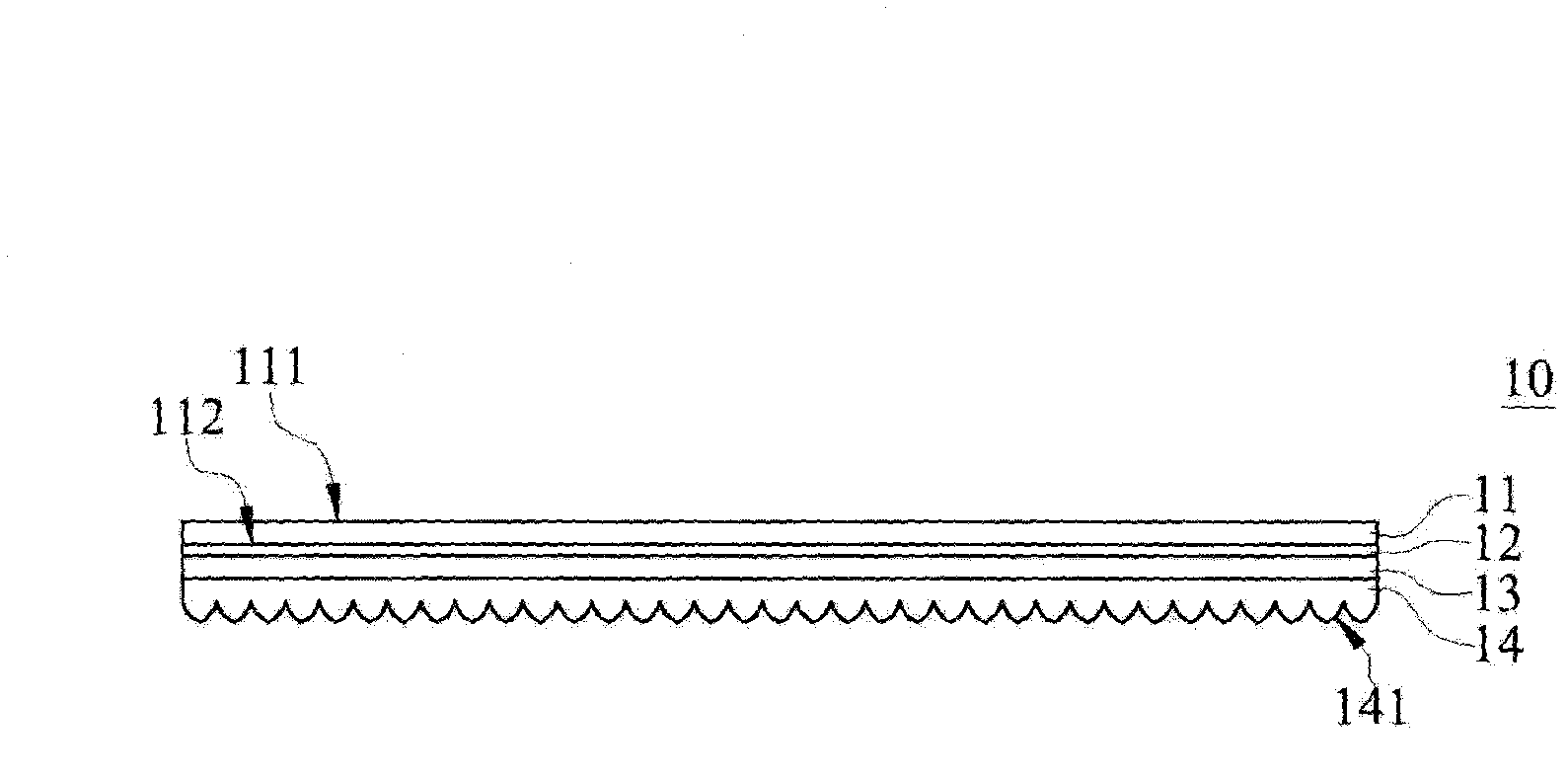

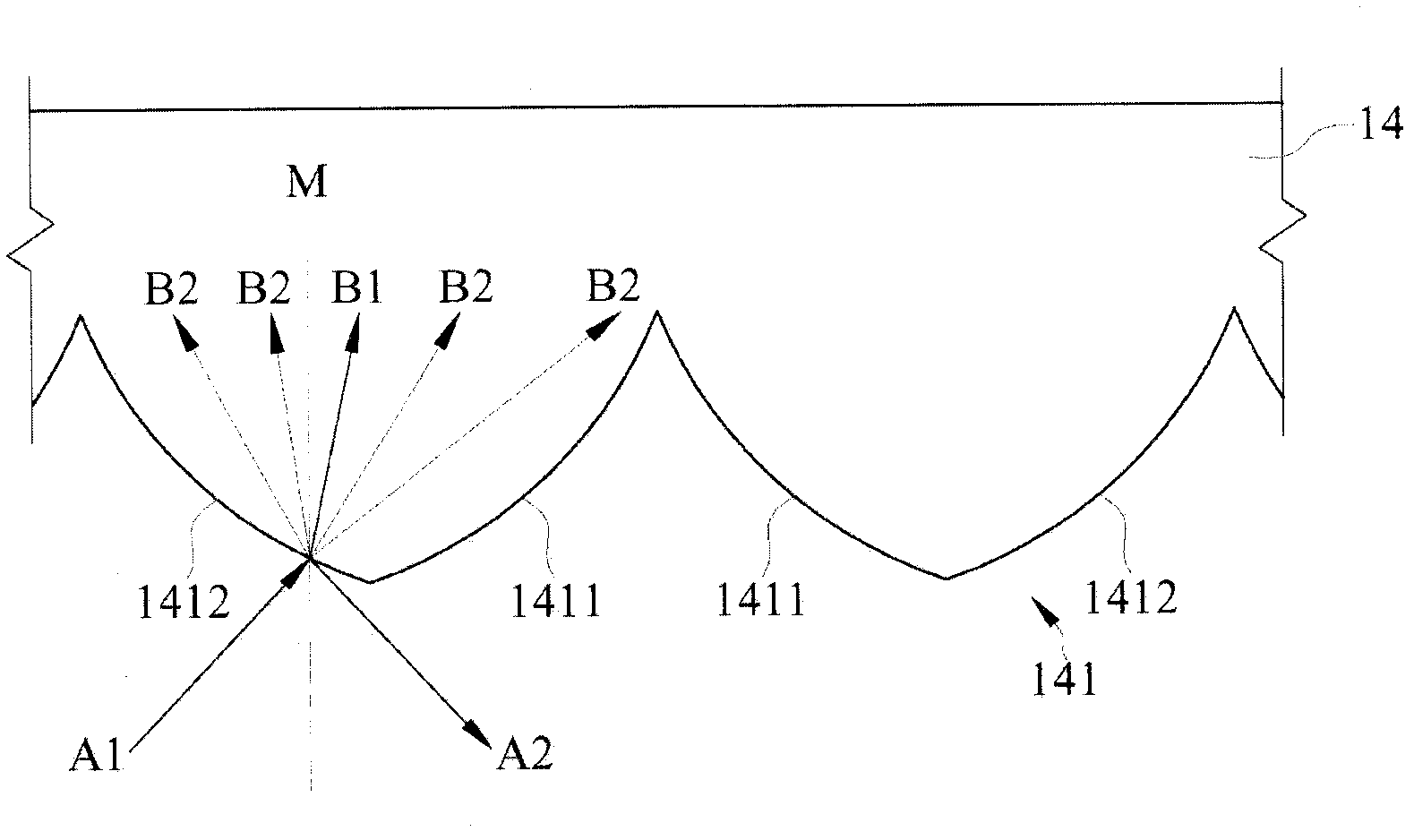

[0031] Please refer to figure 1 and figure 2 , figure 1 Shown is a schematic structural diagram of a fingerprint recognition device of an embodiment, figure 2 Shown is a structural cross-sectional view of the finger-pressing board of an embodiment.

[0032] The finger board 10 according to an embodiment of the present invention is used in a fingerprint recognition device, and the fingerprint recognition device includes a finger board 10 (Finger Board), an imaging device 20 and at least one light emitting device 30 . When a finger C is placed on the acupressure board 10 , the light emitting element 30 can be driven to emit a light A toward the acupressure board 10 . The light A enters the acupressure board 10 and irradiates the finger C, and produces a fingerprint pattern with light and dark contrast, so that the image capturing element 20 achieves the effect of capturing and identifying fingerprints. Wherein, the path of light A in the drawings is just an example of one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com