Automatic container formation system for lead-acid storage battery

A lead-acid battery, internalization technology, applied in the direction of lead-acid battery, lead-acid battery construction, sustainable manufacturing/processing, etc. The effect of producing, improving working conditions and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

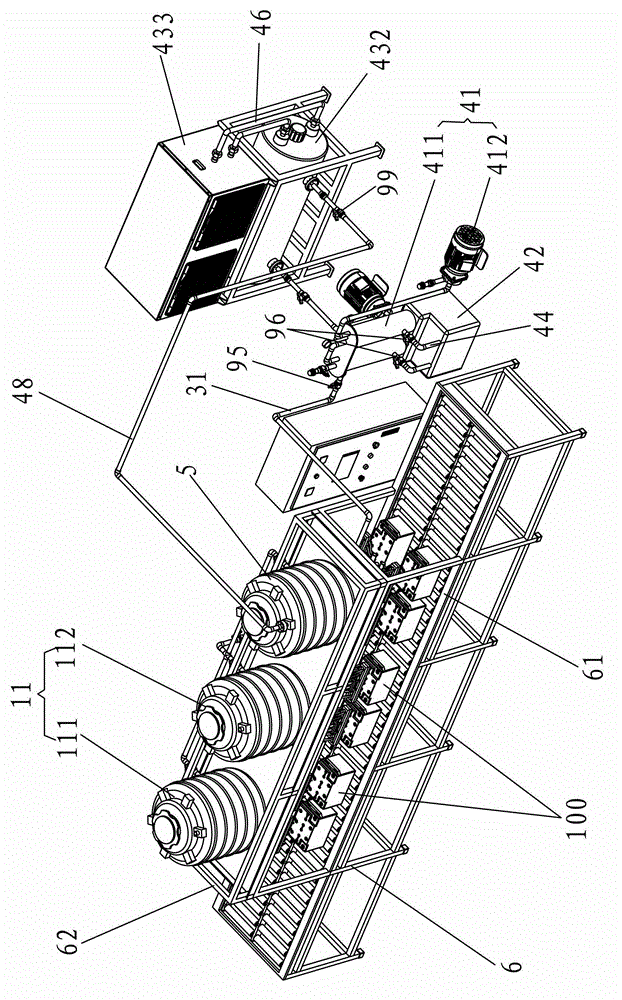

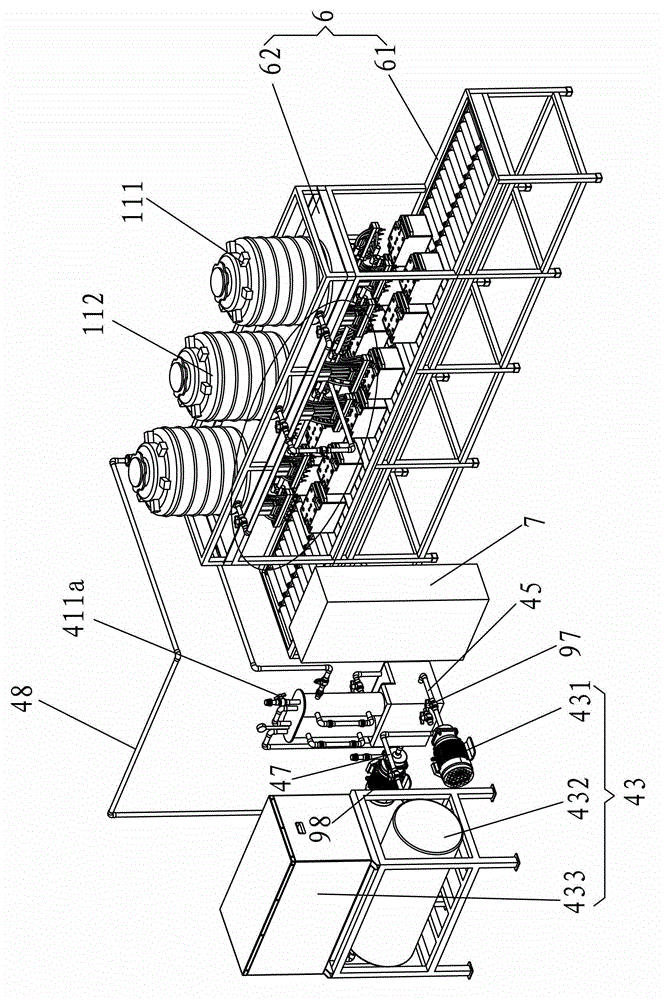

[0050] A kind of automatic internalization system of lead-acid storage battery of the present invention, as Figure 1-9 As shown, it includes an acid liquid input device, an acid feeding nozzle 2, an acid liquid return device 3, an acid liquid cooling device 4, a circulating acid tank 5, a bracket 6 and an electric control cabinet 7.

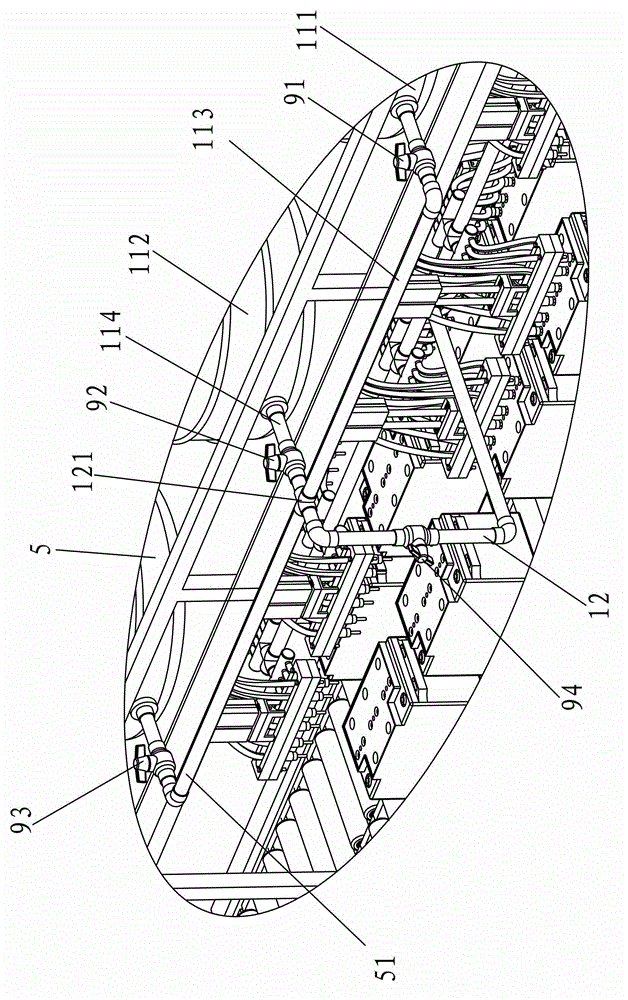

[0051] The acid feed nozzle 2 is a cylindrical structure, and the acid feed nozzle 2 has an acid liquid input channel 21, an acid liquid delivery channel 22 connected with the acid liquid input channel 21, and an acid liquid delivery channel 22 connected with the acid liquid delivery channel 22. The connected acid solution output port 23, the acid solution delivery channel 22 is erected with an acid pumping tube 8, and the acid solution delivery channel 22 is parallel to the axis where the acid solution tube 8 is longitudinally located, and the acid solution input channel 21 is connected to the acid pumping tube 8. The axes where the longitudina...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap