Fully-automatic electric-heating film tube machining device with loading and unloading functions

A fully automated, electrothermal film tube technology, applied in the direction of spraying devices, heating element shapes, etc., can solve the problems of inability to achieve high-efficiency production, inability to obtain high-precision, inability to obtain consistent coordination of equipment work, etc., to achieve The effect of high precision and high efficiency, accurate loading and unloading function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

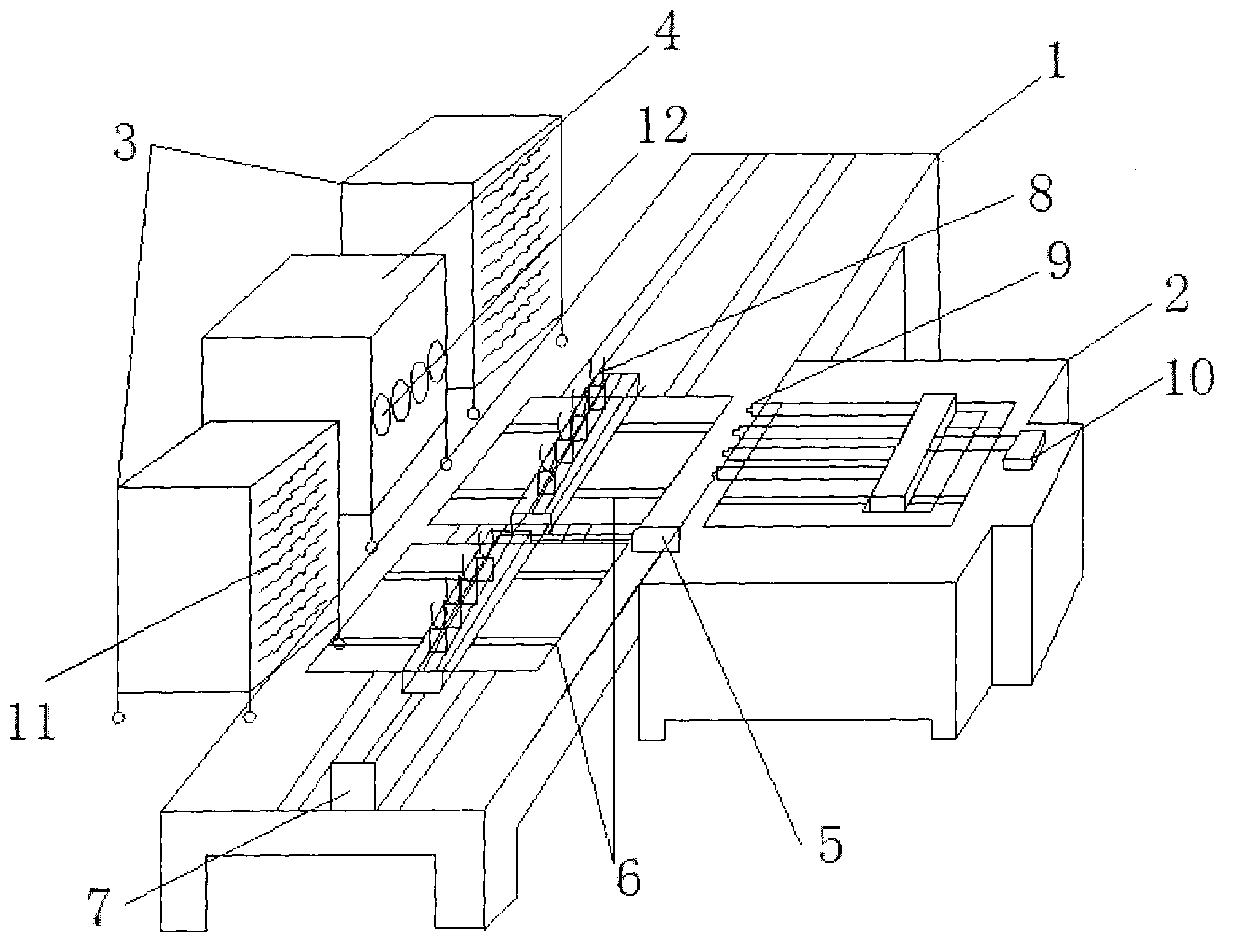

[0020] As shown in the figure, the fully automatic electrothermal film tube processing device with loading and unloading functions involved in the present invention is composed of a manipulator clamping mechanism 1, a nozzle clamping mechanism 2, turnover boxes I and II3, and a sintering furnace 4. The manipulator clamping mechanism It is a vertical elongated working frame, on the left side of the gripping mechanism of the manipulator, the turnover box I, sintering furnace, and turnover box II are placed in sequence, and the gripping mechanism of the nozzle is on the right side of the gripping mechanism of the manipulator, which is opposite to the sintering furnace. .

[0021] In the clamping mechanism part of the manipulator, two groups of finger assemblies are slidingly connected with the horizontal linear slide rails I and II controlled by the servo motor I5, and the horizontal linear slide rails I and II are fixed on the metal plate 6, and the metal plate and the servo moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com