Wheel loader

A wheel loader and front wheel technology, applied in the direction of motors, electrical devices, steering mechanisms, etc., can solve the problems of large-scale hydraulic devices, increased energy consumption, and increased adverse effects on the environment, so as to reduce energy The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, the wheel loader of the present invention will be specifically described with reference to the drawings, taking a hybrid wheel loader as an embodiment.

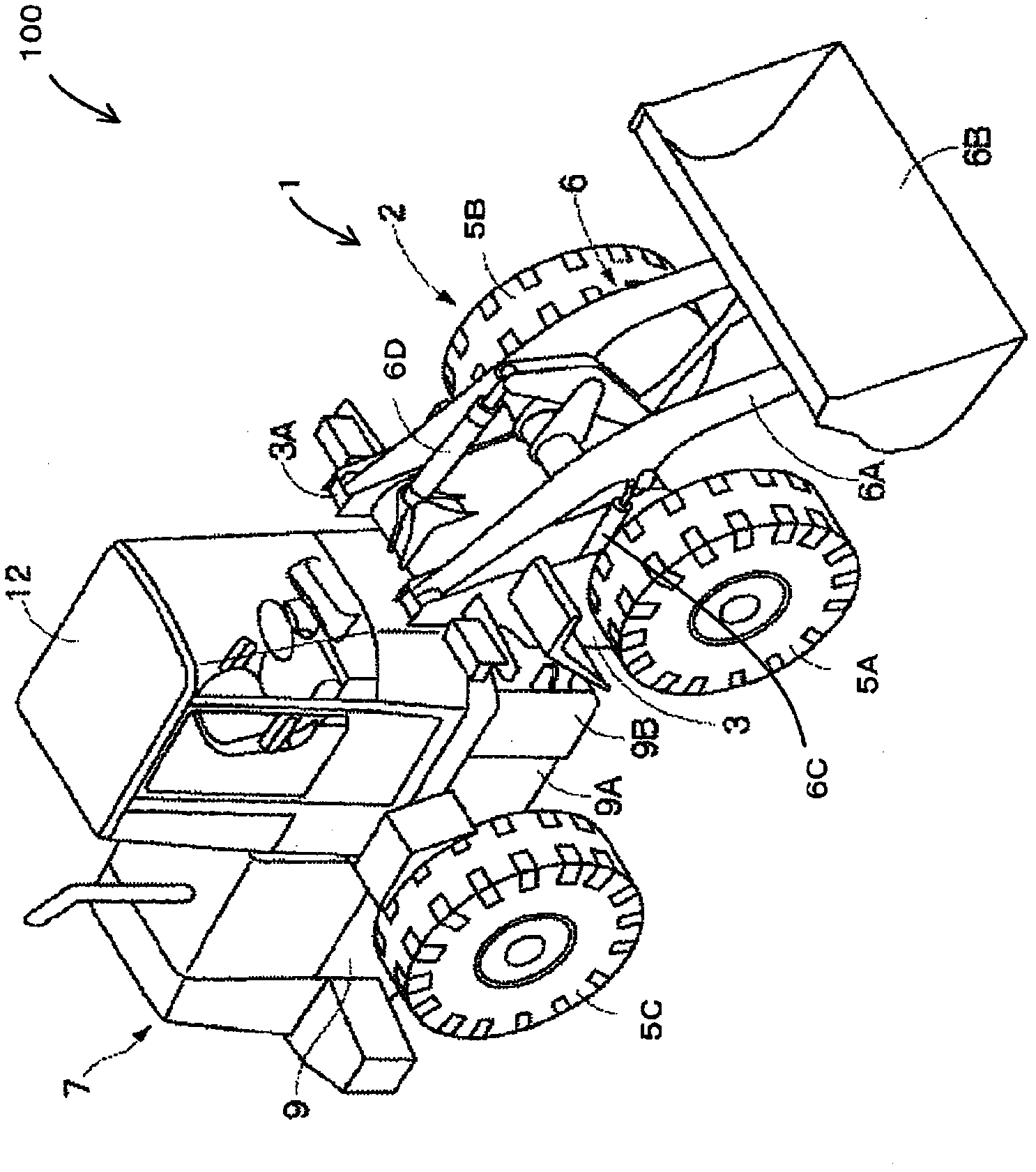

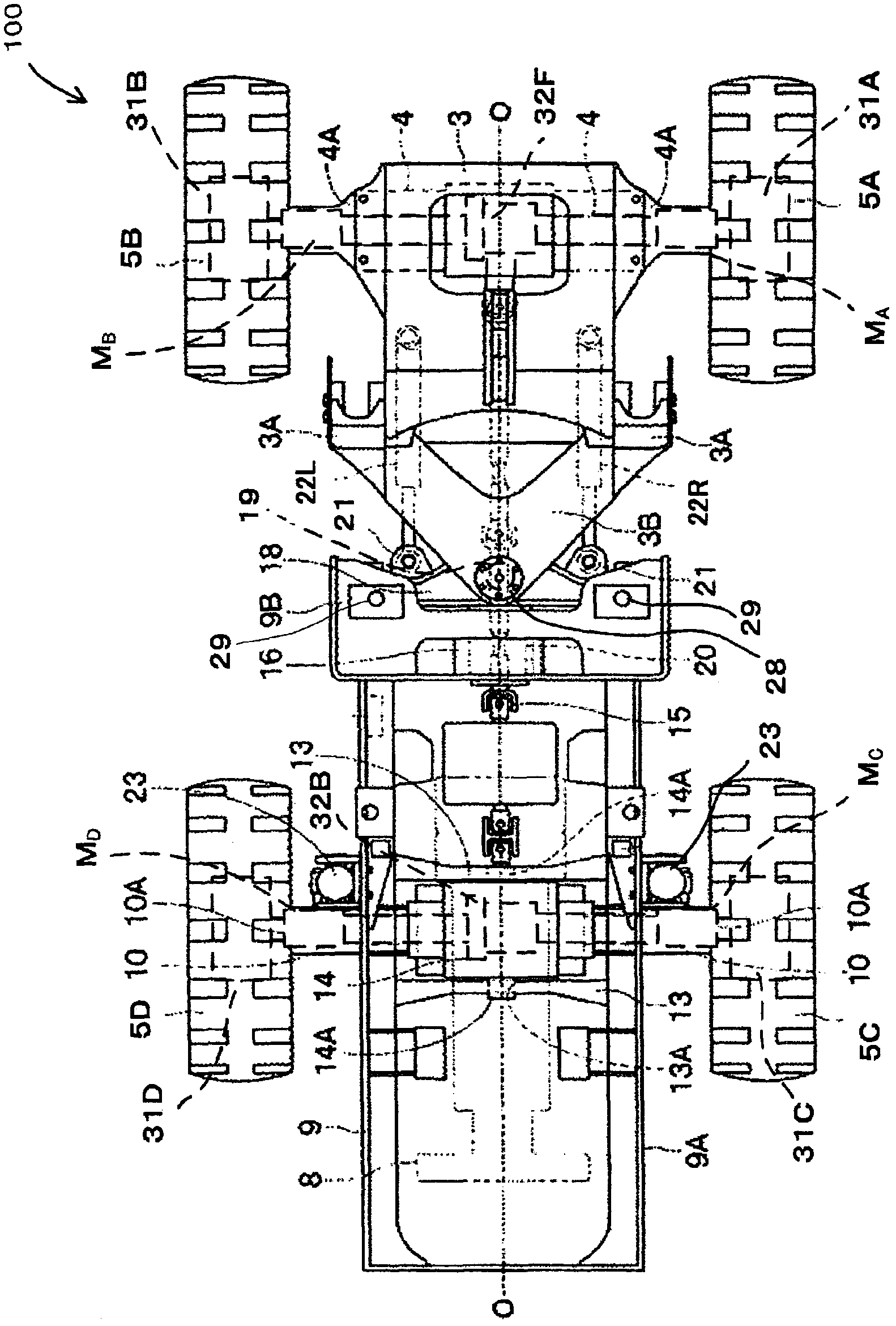

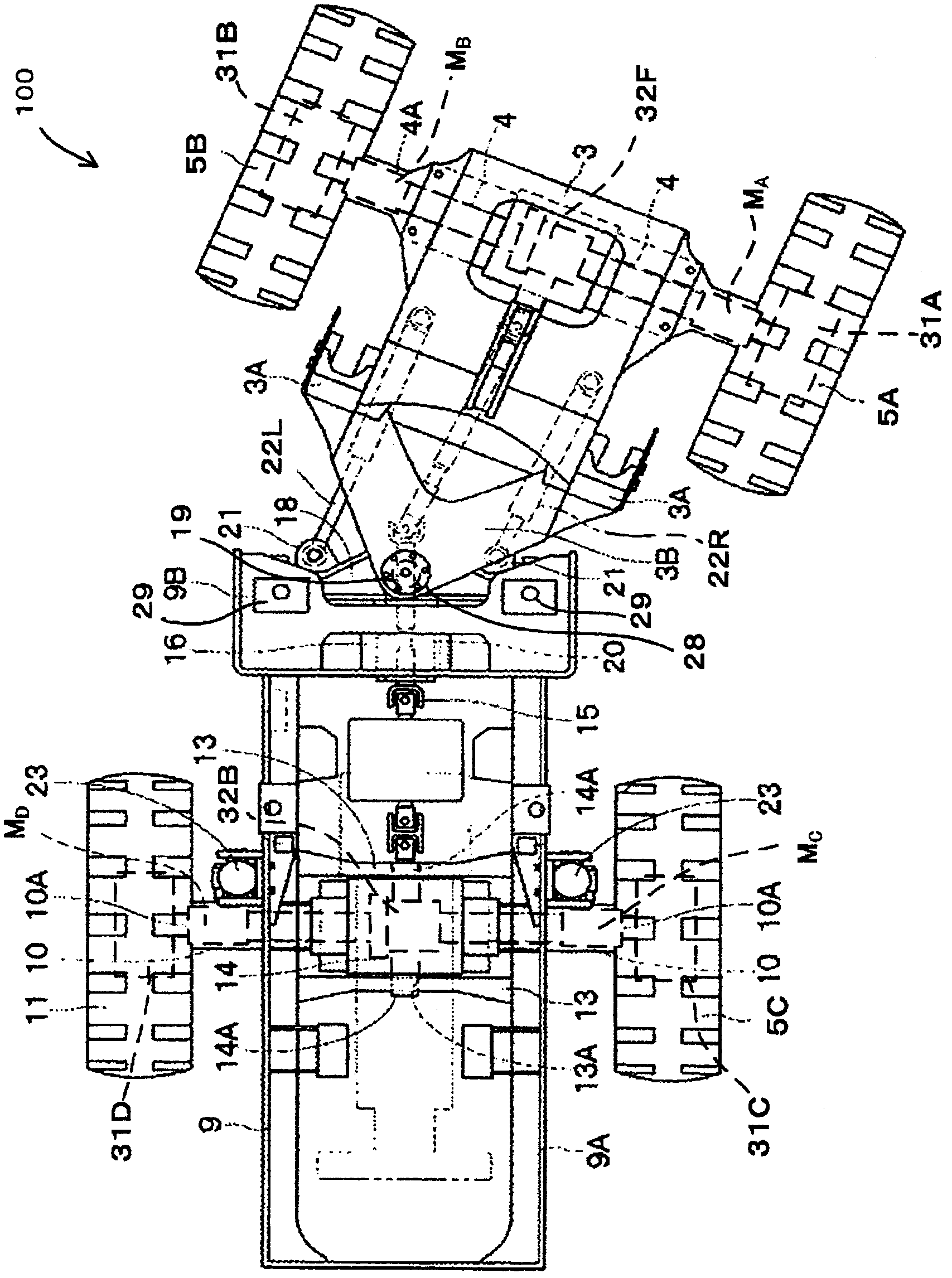

[0027] figure 1 It is a three-dimensional view of the appearance of a hybrid wheel loader, figure 2 yes figure 1 A top view of the hybrid wheel loader shown, image 3 yes figure 2 A top view of the wheel loader shown in its flexed state, Figure 4 yes figure 1 Side view of the hybrid wheel loader shown. But when Figure 2 ~ Figure 4 in, omitted figure 1 Illustration of work equipment (buckets) shown.

[0028] as described below, Figure 1 ~ Figure 4 The illustrated hybrid wheel loader 100 is a work vehicle having an articulated body 1 in which a front body 2 and a rear body 7 are flexibly connected by a joint frame 18 .

[0029] The front body 2 is arranged on the front side of the hybrid wheel loader 100, and includes: a front frame 3 formed in a substantially box shape; a front axle 4 provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com