Pressure reducing and defoaming device for molten glass, molten glass manufacturing method, and glass product manufacturing method

A technology of molten glass and manufacturing method, applied in glass manufacturing equipment, manufacturing tools, glass furnace equipment, etc., can solve the problems of difficulty in degassing and lowering the temperature of molten glass, and achieve the effect of preventing temperature reduction and efficient degassing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, the vacuum degassing apparatus of the molten glass of this invention is demonstrated in detail based on embodiment shown in drawing.

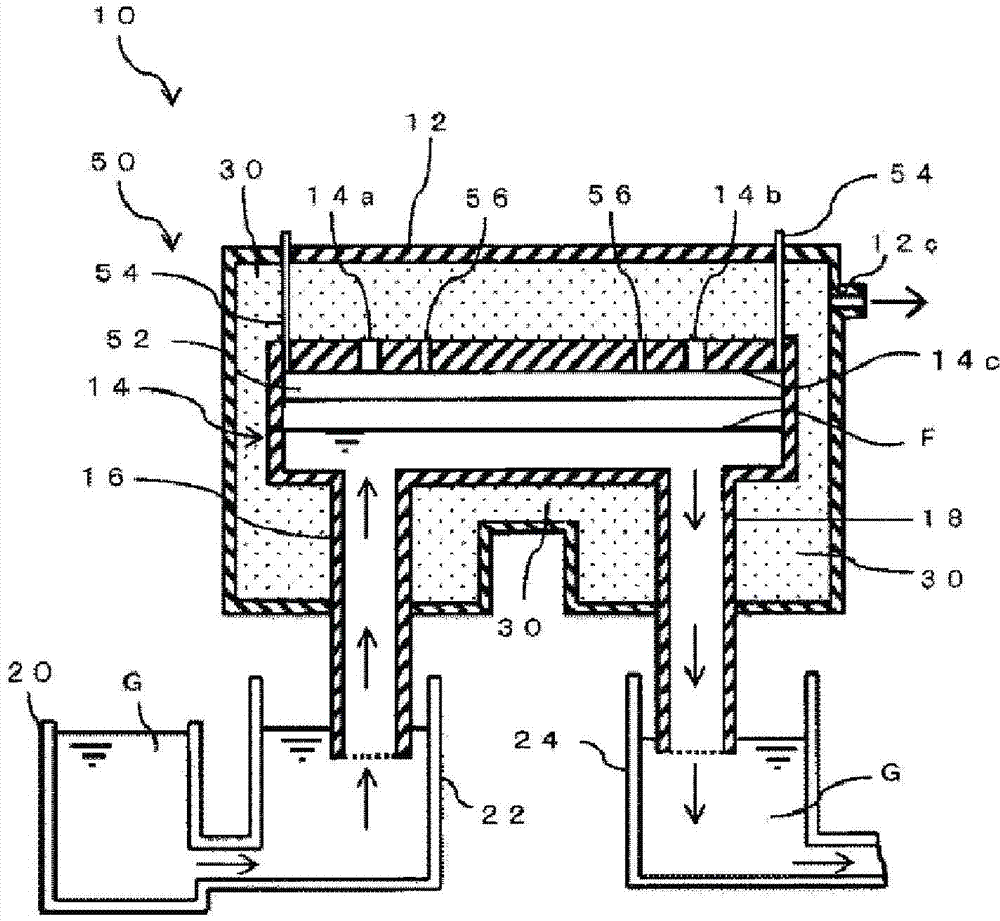

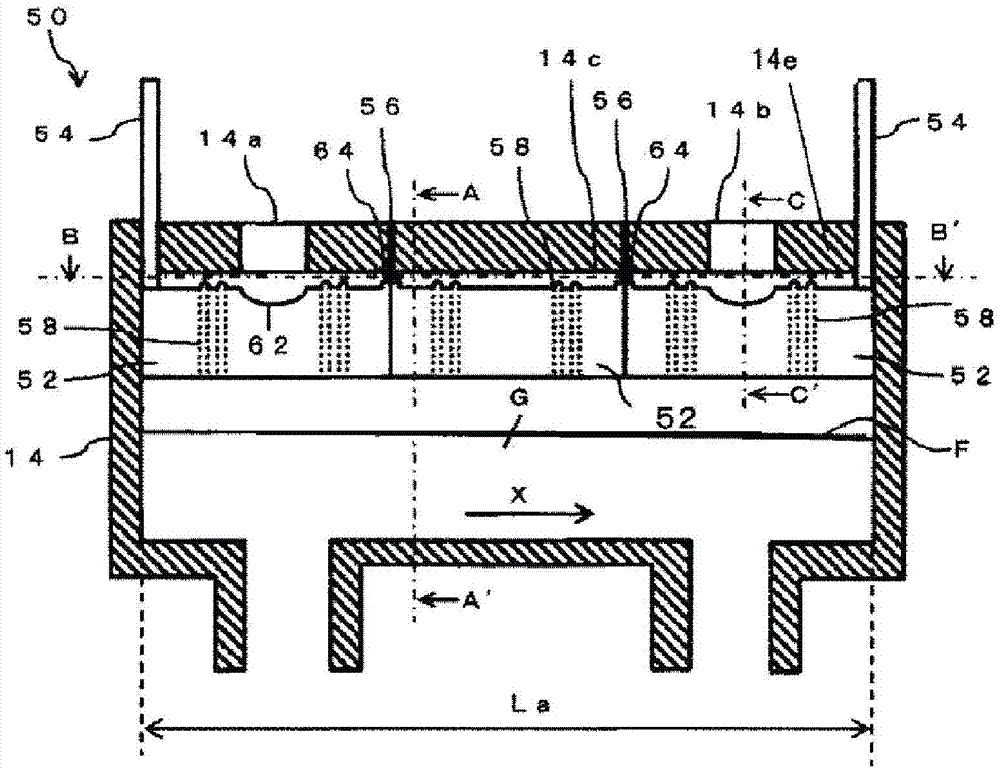

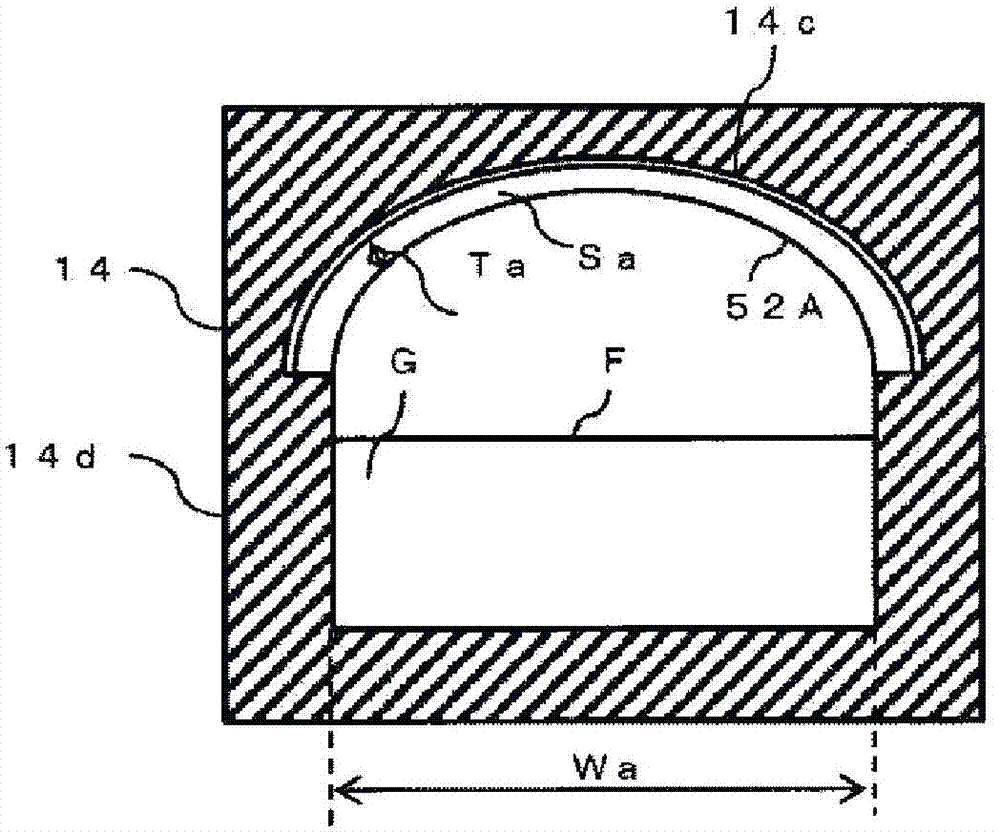

[0034] figure 1 It is a schematic side sectional view of the vacuum degassing apparatus (henceforth the vacuum degassing apparatus of this invention) of the molten glass concerning embodiment of this invention.

[0035] figure 1 The shown vacuum degassing device 10 has a vacuum housing 12 whose interior can be kept in a reduced pressure state. The decompression housing 12 is made of metal, and is provided with a suction port 12c for decompressing the inside by evacuation.

[0036] A vacuum degassing tank 14 is accommodated in the decompression housing 12 . Suction holes 14a, 14b communicating with the decompression housing 12 are provided on the upper portion of the degassing degassing tank 14 . By evacuating the decompression housing 12 from the suction port 12c using a vacuum pump (not shown), the inside of the degassi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com