A hermetic compressor

A closed compressor and muffler technology, applied in the field of compressors, can solve the problems of increasing the size of the compressor, the collision of the discharge muffler, and affecting the efficiency of the compressor, so as to increase the internal volume, reduce the pressure loss, and increase the efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

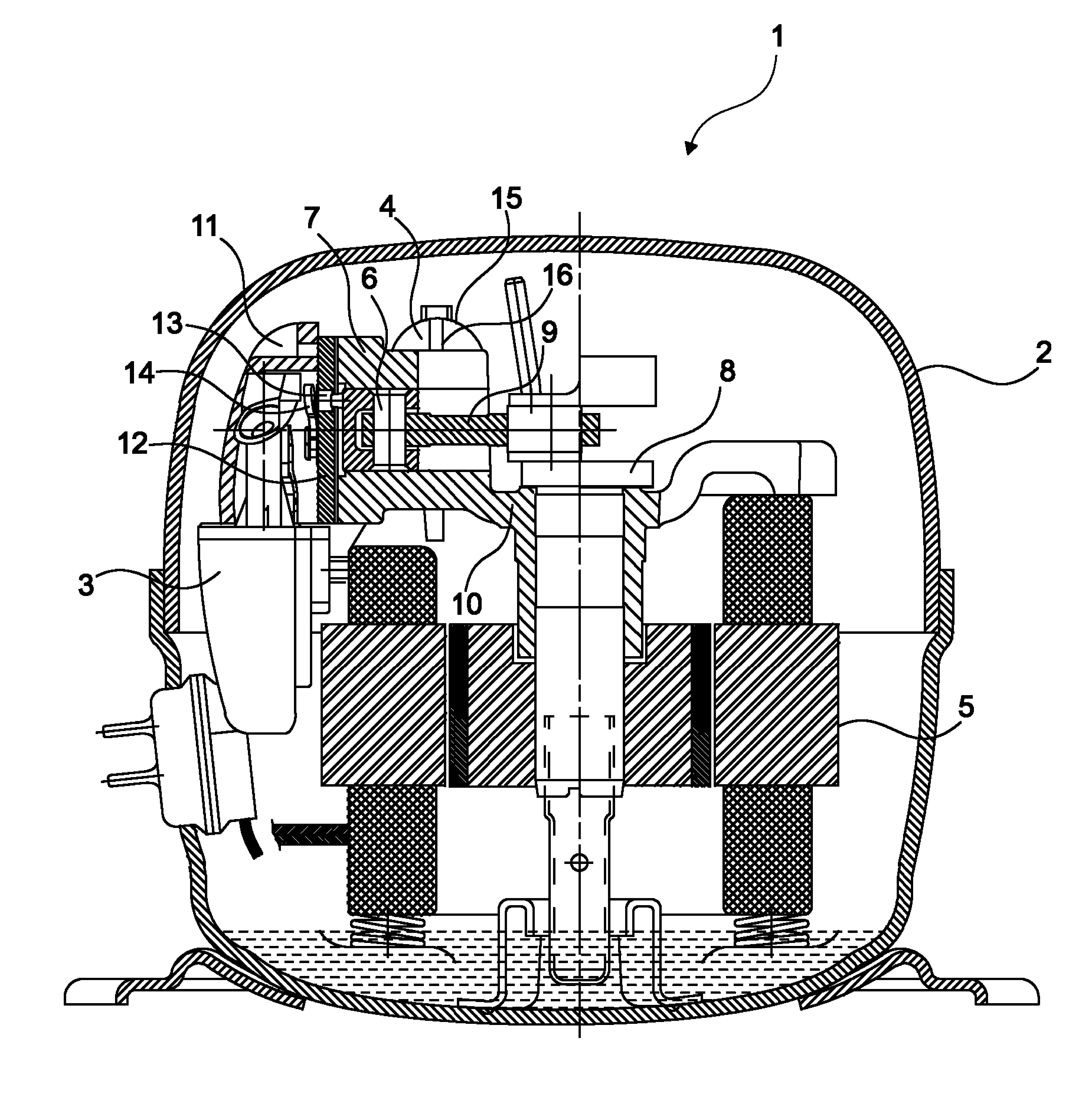

[0037] In a cooling device such as a refrigerator, a refrigerant fluid is circulated by a hermetic compressor (1).

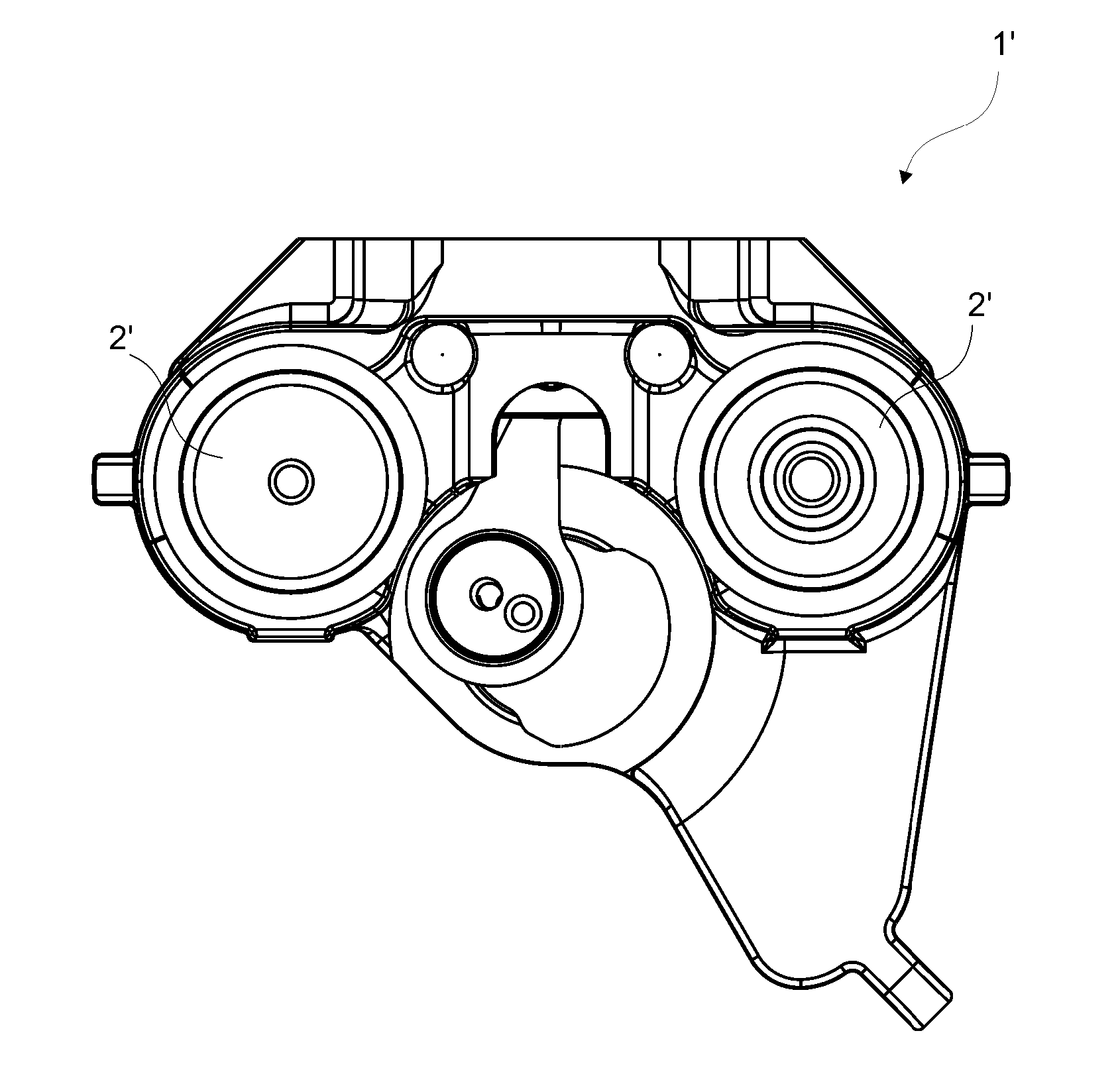

[0038] The hermetic compressor (1) comprises: a housing (2) carrying components therein; a motor (5) placed inside the housing (2); a cylinder (6) for pumping a refrigerant fluid; a piston (7), which acts in the cylinder (6) for compressing the refrigerant fluid into said cylinder (6) bore; the crankshaft (8), which transfers the motion transmitted from the motor (5); and, piston rod (9), which transfers the motion received from the crankshaft (8) to the piston (7) ( figure 2 ). Rotational motion in the motor (5) is delivered to the piston (7) by the crankshaft (8)-piston rod (9) mechanism and thus causes the piston (7) to reciprocate.

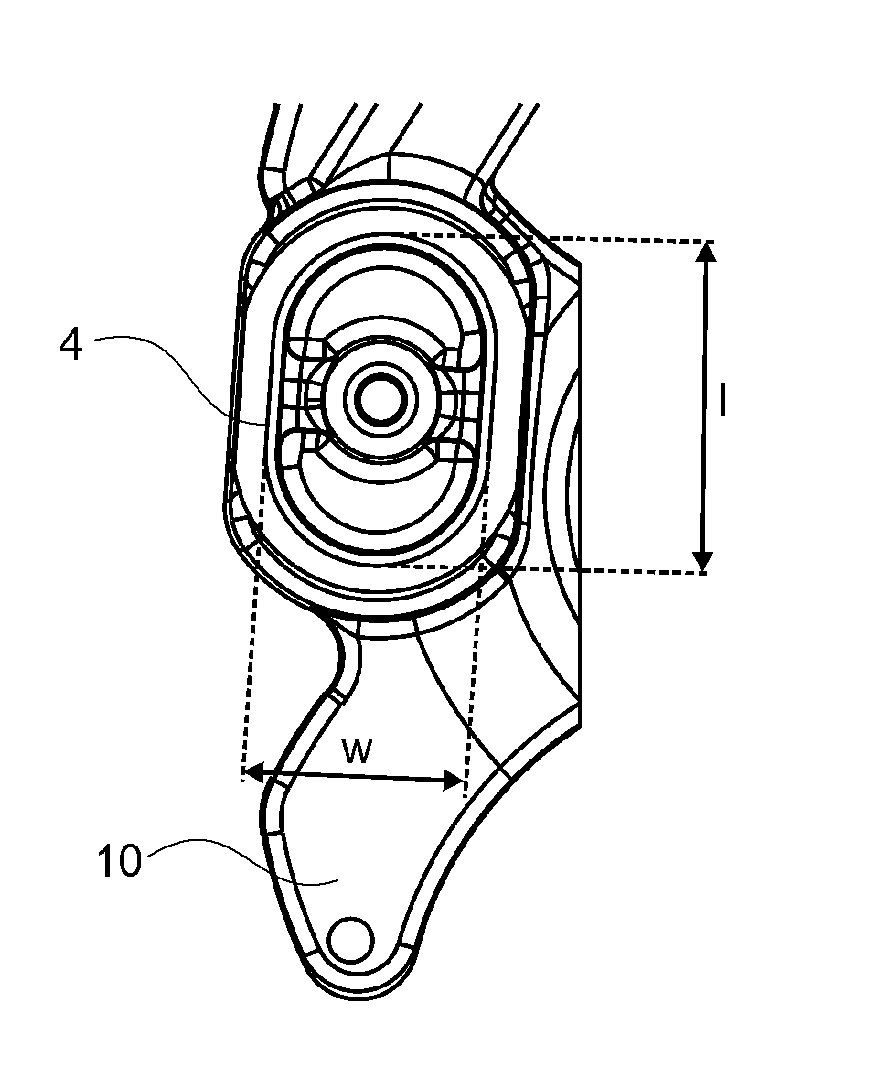

[0039] The hermetic compressor (1) also includes: a cylinder head (11), which is used to circulate refrigerant fluid, which is sucked in and pumped by the movement of the piston (7); a valve table (12), which is placed Betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com