An inorganic silicon-aluminum dry powder coating for exterior walls

A dry powder coating and inorganic silicon technology, applied in the field of coatings, can solve the problems of poor acid and alkali resistance, aging resistance, difficult construction, etc., and achieve the effects of solving compatibility and processing problems, improving mechanical strength, and excellent weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

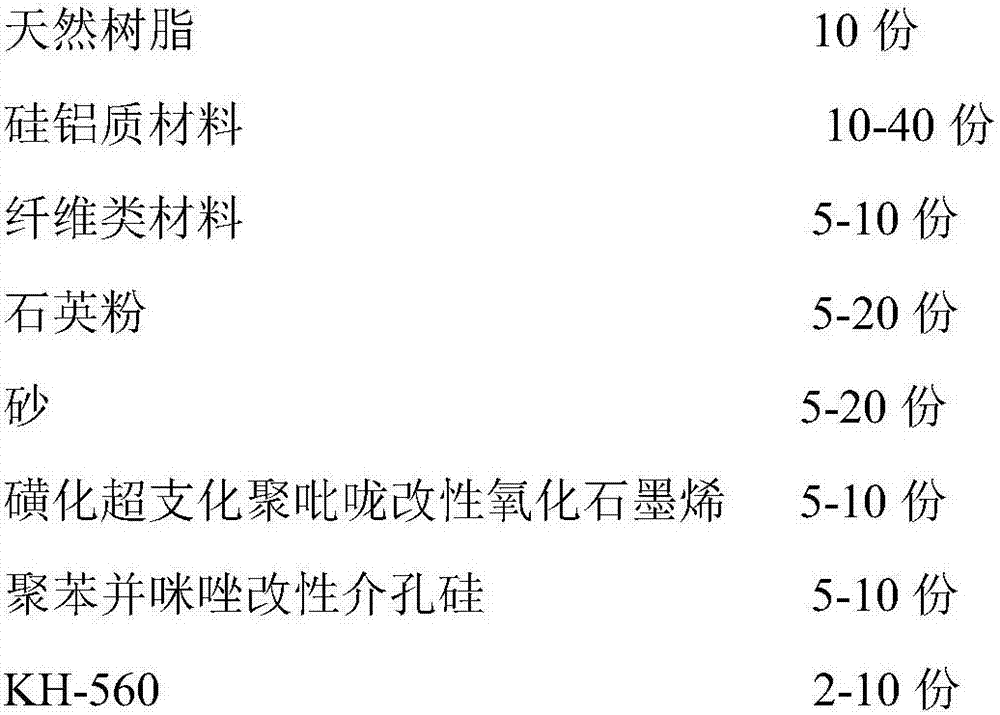

Method used

Image

Examples

preparation example Construction

[0045] F1: Sulfonated hyperbranched polypyrrone modified graphene oxide, prepared by the following method:

[0046] (1) Preparation of naphthalene anhydride-capped hyperbranched polypyrrole solution

[0047] Add 1 mole of 1,3,5-tris(4-naphthyloxy-1,8-dioic acid) trimellitic anhydride and 2000ml m-cresol in a completely dry three-necked flask, stir under nitrogen protection, when the trianhydride After completely dissolving, add 0.5 mole of 3,3'-diaminobenzidine, stir at room temperature for 30 minutes, heat to 85°C, react for 3.5h, then react at 185°C for 4.5h; after the reaction, drop to At room temperature, naphthalene anhydride-capped hyperbranched polypyrrole solution is obtained;

[0048] (2) prepare the hyperbranched polypyrrole modified by diaminopolyethylene glycol

[0049] To the naphthalene anhydride-capped hyperbranched polypyrrole solution obtained in step (1), add 2 moles of diaminopolyethylene glycol with an average degree of polymerization of 226, stir at room...

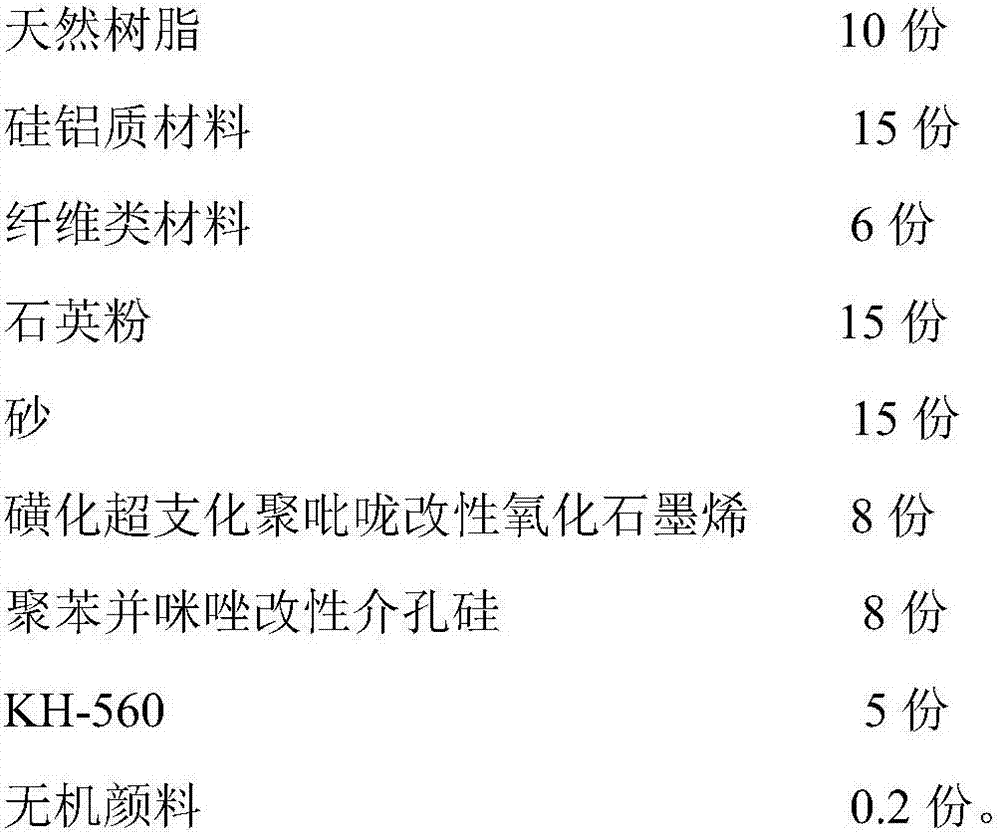

Embodiment 1

[0091] In parts by weight, add 10 parts of A1, 15 parts of B1, 6 parts of C1, 8 parts of F1, 8 parts of G1, 5 parts of H1 and 0.2 parts of I1 into the mixer and mix thoroughly for 10 minutes, add 15 parts of D1 and 15 parts of E1 continued to mix for 5 minutes and discharged. Stir evenly according to the ratio of powder to water of 1:0.4, and it can be used according to the weight ratio.

Embodiment 2

[0093]In parts by weight, add 10 parts of A1, 15 parts of B1, 6 parts of C1, 8 parts of F2, 8 parts of G2, 5 parts of H1 and 0.2 parts of I1 into the mixer and mix them thoroughly for 10 minutes. Add 15 parts of D1 and 15 parts of E1 continued to mix for 5 minutes and discharged. Stir evenly according to the ratio of powder to water of 1:0.4, and it can be used according to the weight ratio.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance | aaaaa | aaaaa |

| alkali resistance | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com