Skin scratching device for citrus peeling machine

A peeling machine and peeling technology, which is applied in applications, peeling of vegetables or fruits, food science, etc., can solve the problems of uneven incision quality, low effective incision rate, easy to damage orange flesh, etc., to improve accuracy and Continuity, improve efficiency, and avoid missing strokes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: (a peeling device for fruit diameter≧60~<70mm citrus and its application 1)

[0030] The device includes a citrus delivery system and a sensor system and a peeling knife system; wherein,

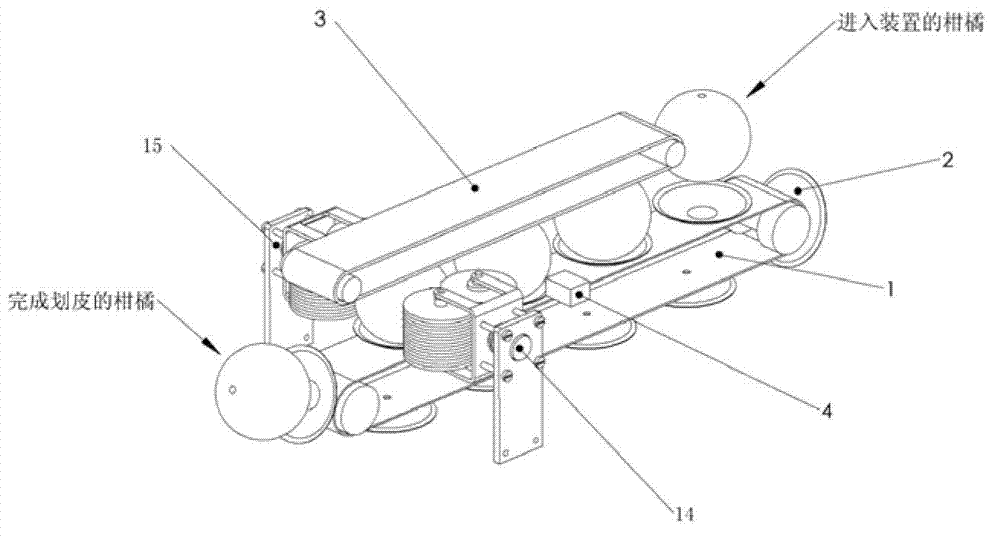

[0031] The citrus conveying system is composed of a conveyor belt 1, a tray 2 and a pressing belt 3; wherein, the tray 2 has a diameter of 100mm, is arranged without intervals according to the forward direction of the conveyor belt 1, and is fixed on the conveyor belt 1 The upper surface; the compression belt 3 is located parallel to 50 mm above the conveyor belt 1; the conveyor belt 1 and the compression belt 3 move in opposite directions at the same speed;

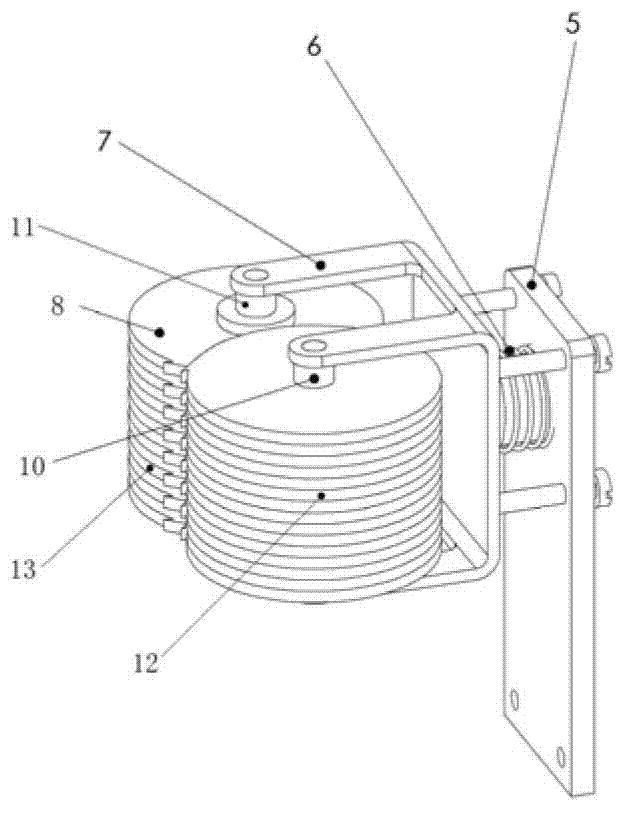

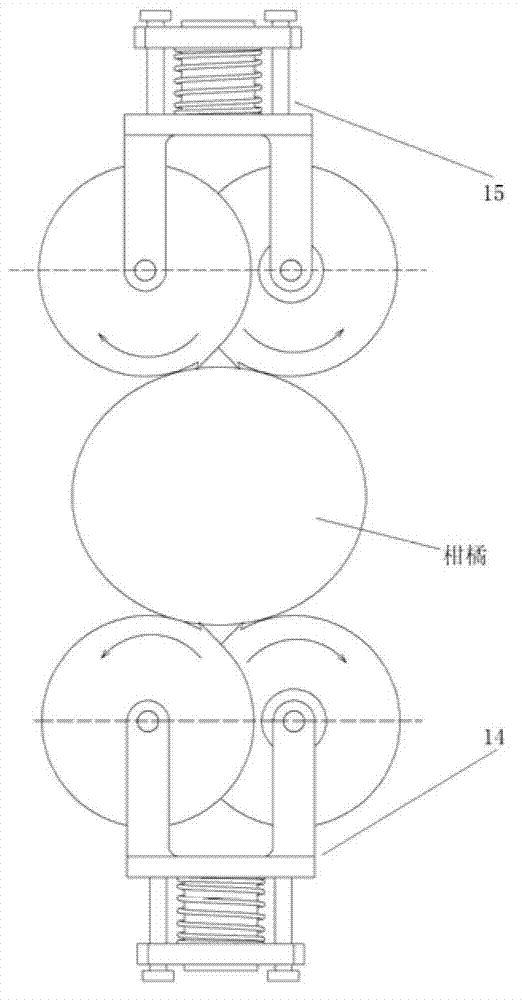

[0032] The skinning knife set system: it is formed by supporting the skinning knife set A14 and the skinning knife set B15; Frame 7 and disk sheet column A12 and disk sheet column B13 are combined; Wherein, described disk sheet column A and B are each to have circular hole, thickness 5mm, diameter 50mm by 8 cente...

Embodiment 2

[0039] Example 2: (a peeling device for fruit diameter≧50~<60mm citrus and its application 2)

[0040] In this example, the diameter of the pallet 2 in the citrus conveying system is 80 mm, and the pressing belt 3 is located in parallel at 40 mm above the conveying belt 1; The sheet pillars B13 are disc sheets 8 each having a round hole, a thickness of 3.5mm, and a diameter of 35mm, and a length of 5mm on its circumference and a barbed hook 9 at an angle of 30 degrees to the circumference tangent. Assemble every two pieces at an interval of 4mm, the distance between the disk axis A10 and the disk axis B11 is 22mm, the distance between the disk column A12 and the disk column B13 is 50mm; the application device is used to peel citrus Time: Conveyor belt 1 moves forward at a speed of 0.2m / s; disc column A12 and disc column B13 rotate at the same speed of 10 rpm but in opposite directions, and can scratch on the outer skin of citrus 5 openings; All the other processing steps are ...

Embodiment 3

[0042] Embodiment 3: (a peeling device for fruit diameter ≧40~<50m citrus and its application 3)

[0043] In this example, the diameter of the tray 2 in the citrus conveying system is 50mm, and the pressing belt 3 is located in parallel at 30mm above the conveying belt 1; The sheet column B13 is to have circular hole, thickness 2mm, diameter 20mm by 3 centers respectively, and be provided with a length 5mm on its circumference and be provided with the disc sheet 8 of the barbed hook 9 of 30 degree angle with the circumference tangent line, press Every two pieces are assembled at an interval of 3mm, the distance between the disk axis A10 and the disk axis B11 is 15mm, and the distance between the disk column A12 and the disk column B13 is 40mm; : Conveyor belt 1 moves forward at a speed of 0.3m / s; disk sheet column A12 and disk sheet column B13 rotate at the same speed of 20 turns / s but in opposite directions, and can scratch 3 pieces on the outer skin of citrus Crossing; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com