Bearing steel tapping alloying control method, bearing steel and preparation method thereof

A control method and bearing steel technology, which is applied in the field of iron and steel smelting, can solve problems such as unsatisfactory alloying and slag washing effects, unsintered alloy and slag materials, and large additions of steel alloy and slag washing materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

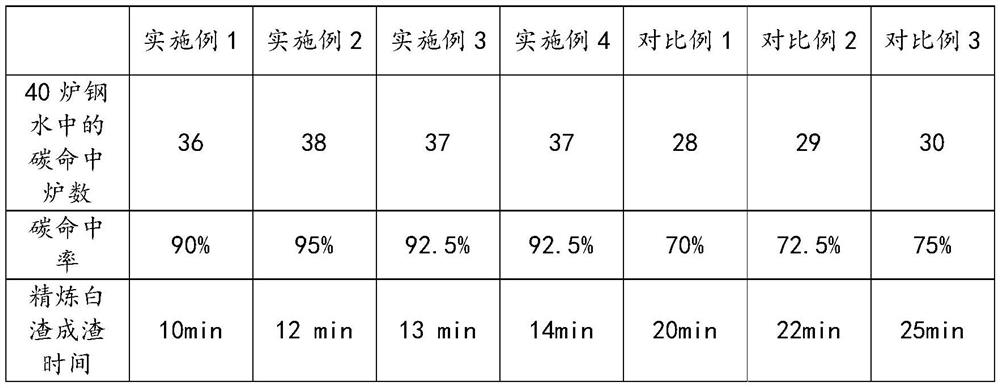

Embodiment 1

[0096] A method for preparing bearing steel is provided, comprising:

[0097] In terms of mass fraction, the above-mentioned components of the bearing steel include: C 0.9%, Si 0.1%, Mn 0.2%, Cr 1.35%.

[0098] The aluminum-iron alloy is placed in the first intermediate silo; the first vibration feed switch is set for the first intermediate silo. Alloys containing silicon, manganese, chromium and carbon are placed in the second intermediate feed bin; a second vibration feeding switch is set for the second intermediate feed bin. The lime in the slag washing material is placed in the high-level silo of auxiliary raw materials, and the conditioner is placed in the third middle silo. The high-level silo and the third middle-level silo for auxiliary raw materials both use flap valve discharge switches.

[0099] When the tapping amount is 20t, turn on the first vibration feeding switch to vibrate the aluminum-iron alloy into the ladle, and the vibration feeding time is 10s.

[0100...

Embodiment 2

[0105] A method for preparing bearing steel is provided, comprising:

[0106] In terms of mass fraction, the above-mentioned components of the bearing steel include: C 1.0%, Si 0.2%, Mn 0.3%, Cr 1.45%.

[0107] The aluminum-iron alloy is placed in the first intermediate silo; the first vibration feed switch is set for the first intermediate silo. Alloys containing silicon, manganese, chromium and carbon are placed in the second intermediate feed bin; a second vibration feeding switch is set for the second intermediate feed bin. The lime in the slag washing material is placed in the high-level silo of auxiliary raw materials, and the conditioner is placed in the third middle silo. The high-level silo and the third middle-level silo for auxiliary raw materials both use flap valve discharge switches.

[0108] When the tapping amount is 30t, turn on the first vibration feeding switch to vibrate the aluminum-iron alloy into the ladle, and the vibration feeding time is 15s.

[01...

Embodiment 3

[0114] A method for preparing bearing steel is provided, comprising:

[0115] In terms of mass fraction, the above-mentioned components of the bearing steel include: C 0.98%, Si 0.15%, Mn 0.25%, Cr 1.40%.

[0116] The aluminum-iron alloy is placed in the first intermediate silo; the first vibration feed switch is set for the first intermediate silo. Alloys containing silicon, manganese, chromium and carbon are placed in the second intermediate feed bin; a second vibration feeding switch is set for the second intermediate feed bin. The lime in the slag washing material is placed in the high-level silo of auxiliary raw materials, and the conditioner is placed in the third middle silo. The high-level silo and the third middle-level silo for auxiliary raw materials both use flap valve discharge switches.

[0117] When the tapping amount is 25t, turn on the first vibration feeding switch to vibrate the aluminum-iron alloy into the ladle, and the vibration feeding time is 14s.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com