Juicer capable of automatically discharging residues

An automatic slag discharge and juicer technology, applied in the field of food processing, can solve the problems of increasing the noise of the juicer, destroying the nutrients of the juice, and not being able to be discharged, so as to ensure nutrition and taste, increase vibration and noise, and improve processing efficiency. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

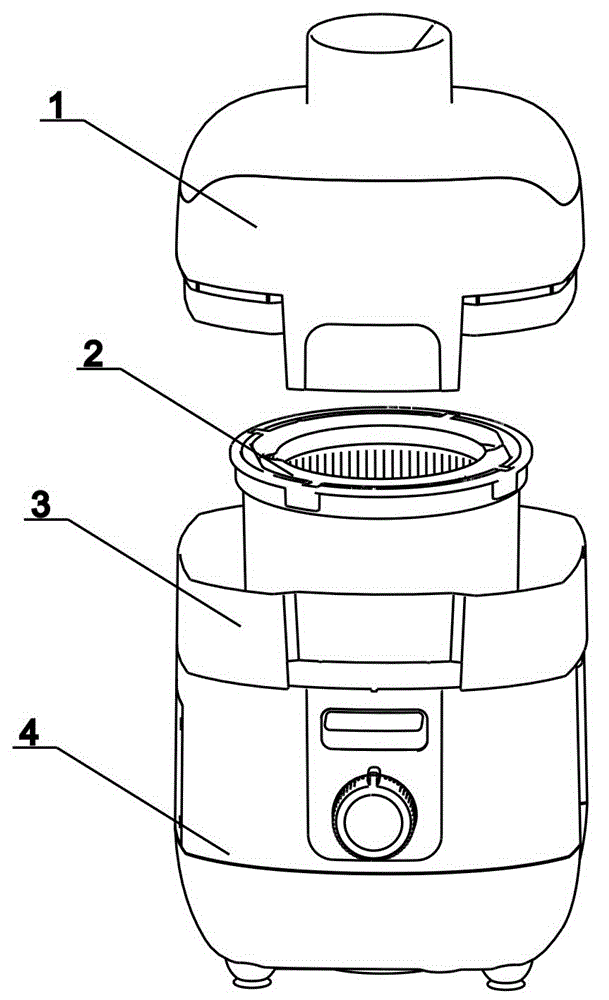

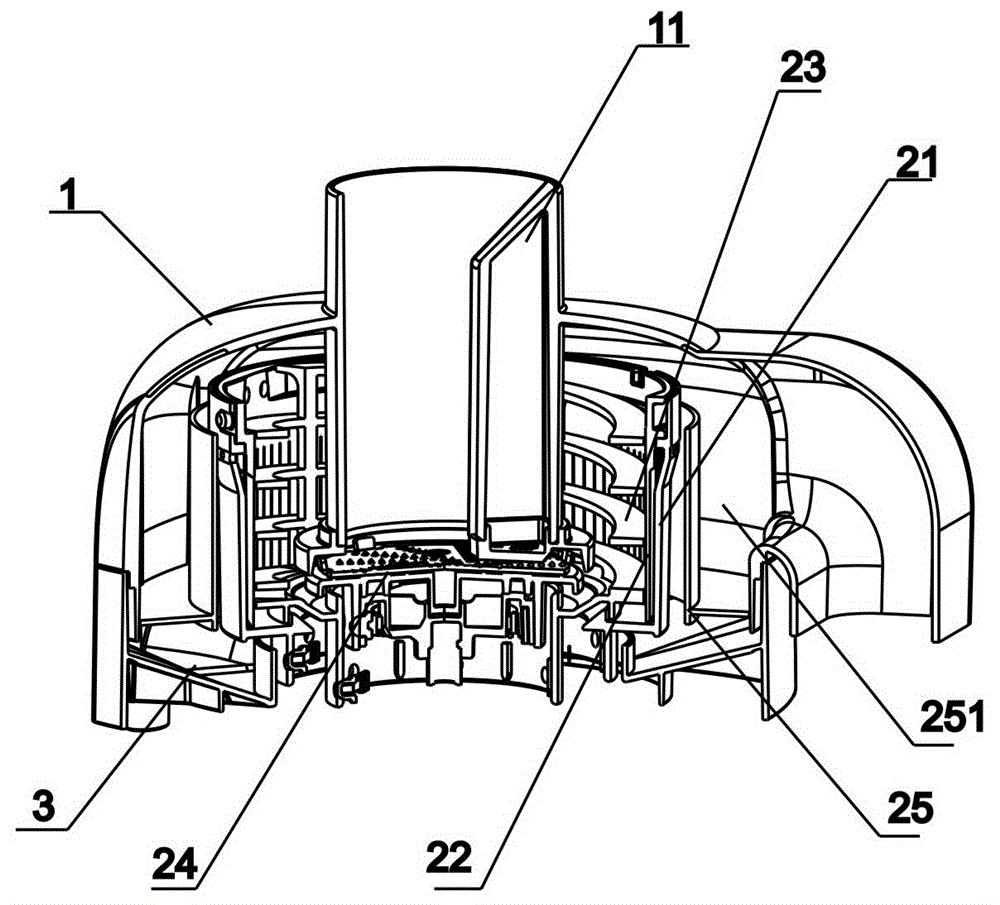

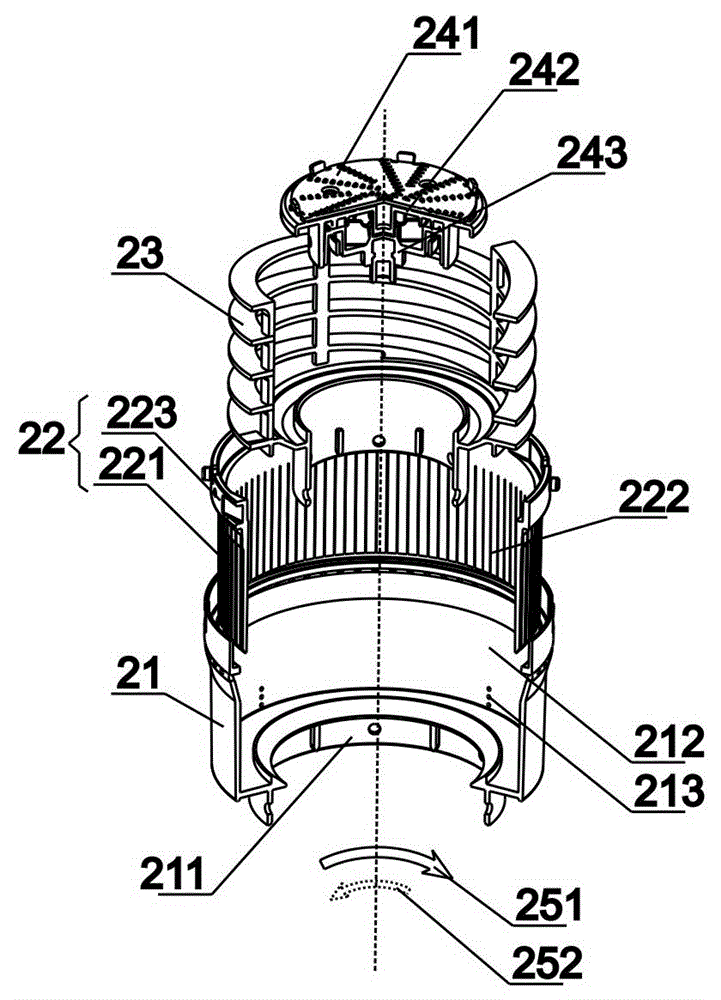

[0040] As a specific embodiment of the automatic slagging juice extractor of the present invention, such as figure 1 , figure 2 , image 3 As shown, the juice extractor includes a loam cake 1, a filter portion 2, a cutter head 24, a juice collection tray 3 and a base 4, and a motor 410 is arranged inside the base 4, and the cutter head 24 and the filter portion 2 Set on the upper part of the machine base 4 and driven by the motor 410, the juice collection tray 3 and the upper cover 1 are arranged on the upper part of the machine base 4, and the upper cover 1 closes the cutter head 24 and the filter part 2. The upper cover 1 is also provided with a feeding tube 11 , the lower end of which is close to the cutter head 24 , and food is input from the feeding tube 11 and is cut.

[0041] Since the structure of the juice extractor is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com