Method for modeling mill end product in mining machinery

A kind of machinery and mill technology, applied in the direction of casting molding equipment, etc., can solve the problems of different core boxes, reduce production efficiency, increase the cost of patterns, etc., and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A molding method for mill end products in mining machinery, characterized in that the method includes the following steps:

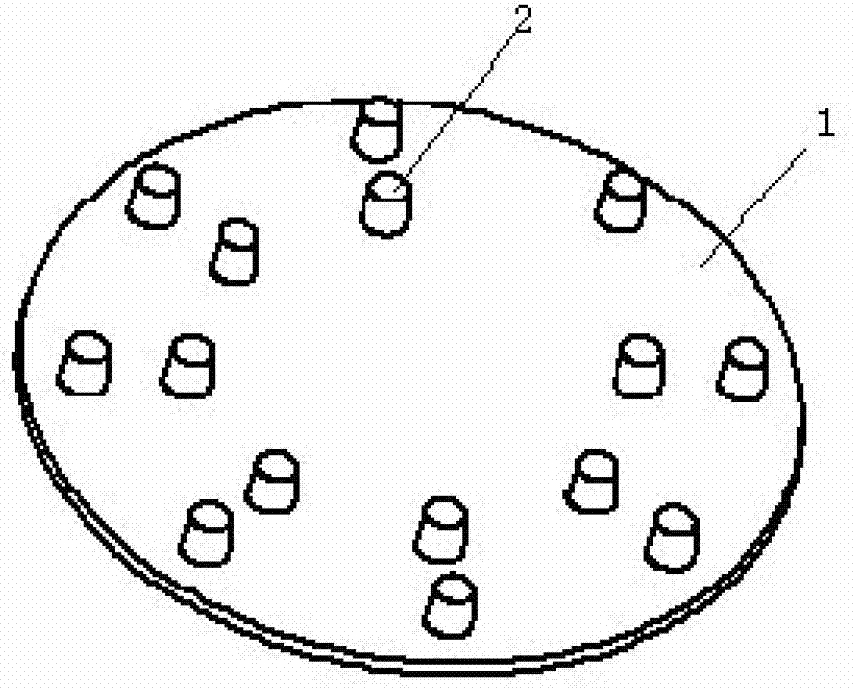

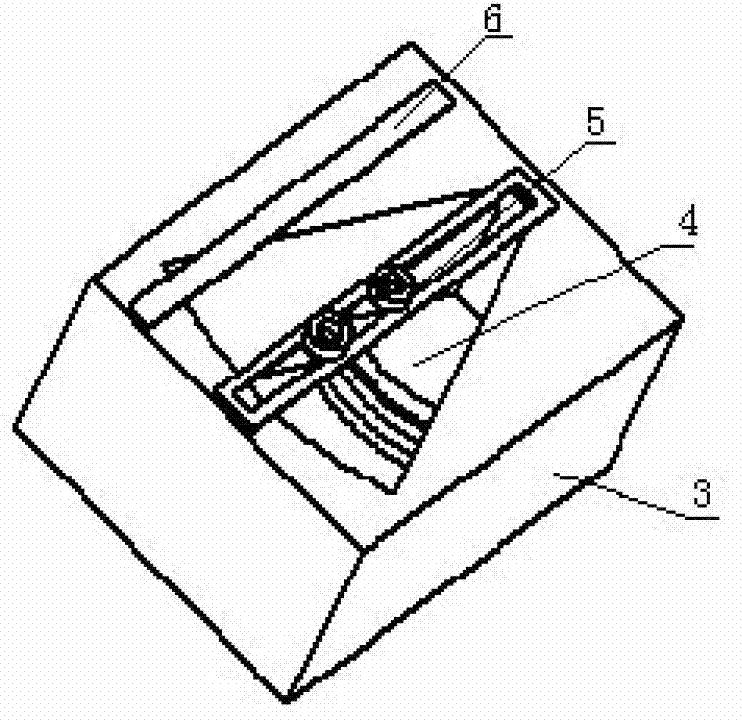

[0025] a. Make tire plate 1 first, such as figure 1 As shown: and on the upper surface of the tire plate 1, a sand core positioning platform 2 is provided, such as figure 2 Shown: prepare fan-shaped core box 3 then, be provided with the scraper plate 6 that scrapes sand core at the top of core box 3;

[0026] b. Place the tire plate 1 in the sand box, adjust the sand core positioning platform 2, and then flow molding sand into the sand box;

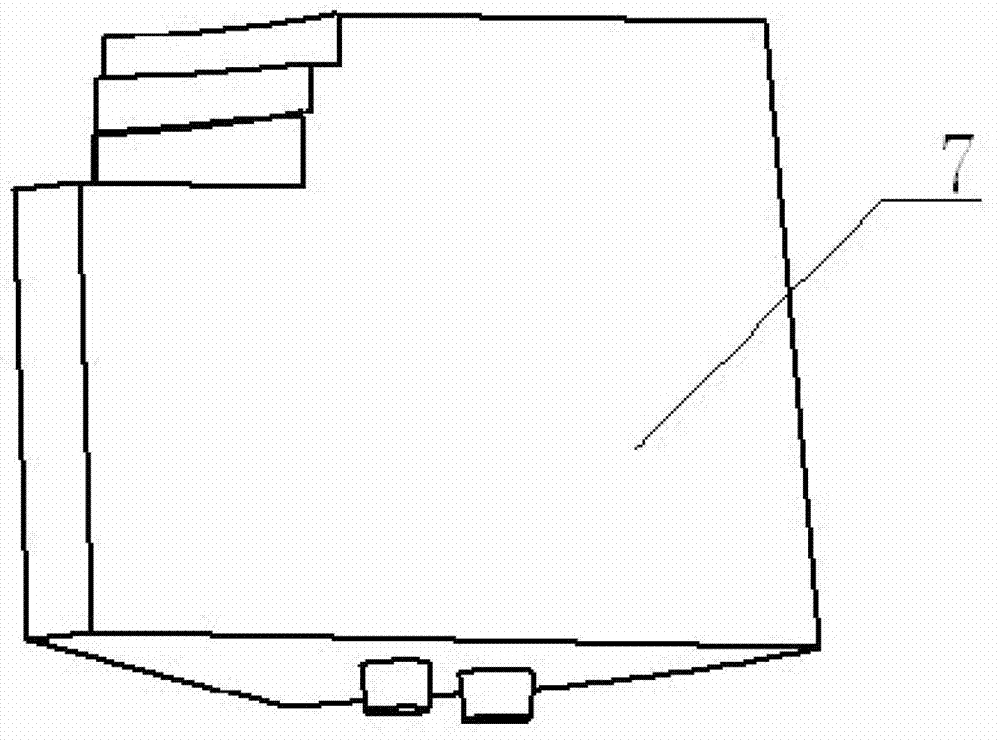

[0027] c. Put the core box 3 into the corresponding loose block 4, after checking that the position of the loose block 4 is accurate, fix the loose block 4, and prepare the quicksand as follows: image 3 The sand core 7;

[0028] d. scrape off the molding sand on the top of the core box 3 by the scraper 6;

[0029] E. prepare sand core positioning block 5 with quicksand, make sand core positioning block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com