Clamping device of blade type precision forging part

A clamping device and precision forging technology, which is applied in the direction of workpiece clamping device, measuring device, optical device, etc., can solve the problems of difficult detection of precision forging blade wool, white light scanning detection equipment cannot be compensated and corrected, and measurement accuracy is affected. Achieve the effects of high reliability and fast positioning and clamping, shorten product inspection cycle, and reduce product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Describe the present invention below in conjunction with specific embodiment:

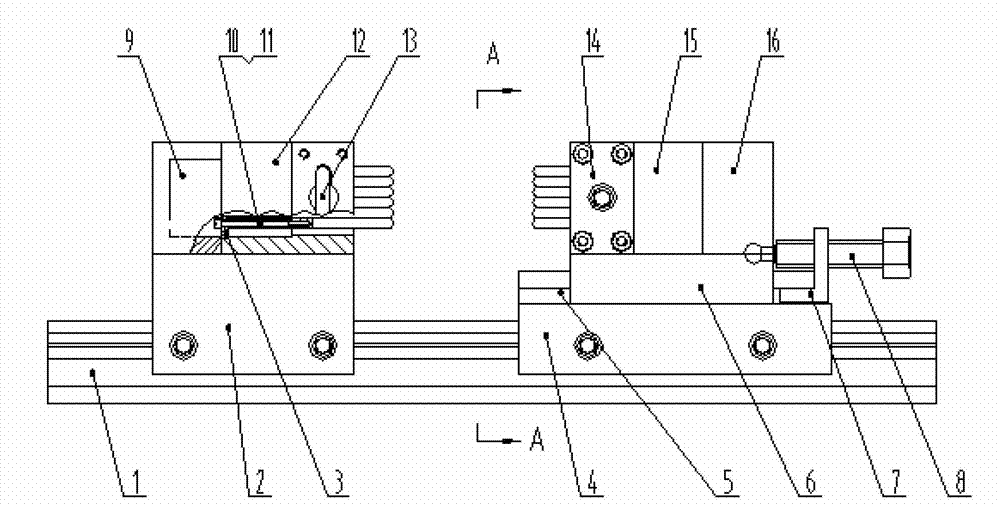

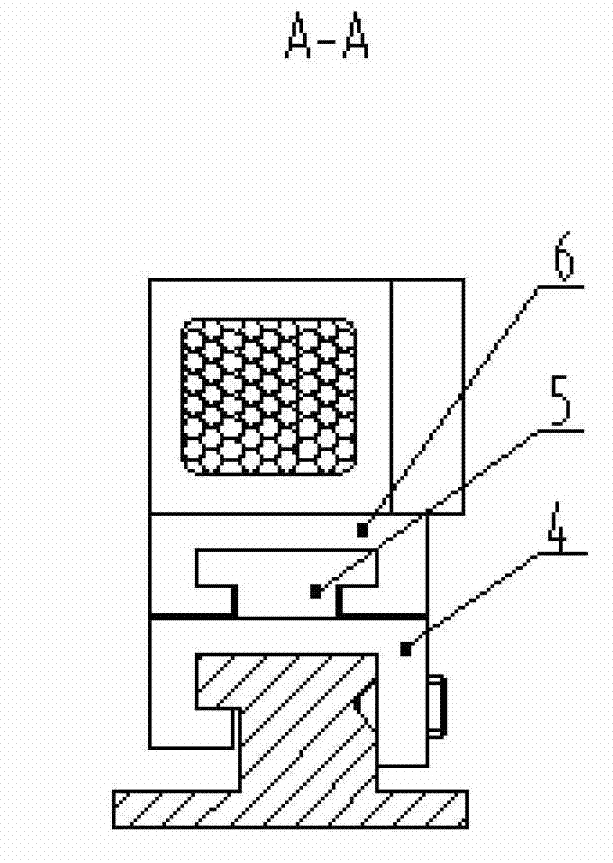

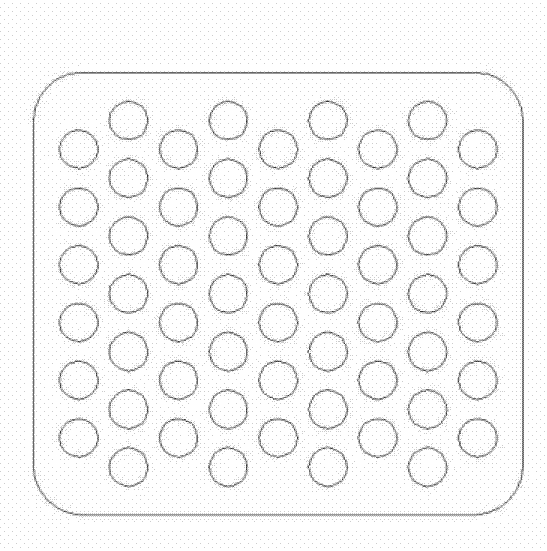

[0023] The clamping device for blade precision forging parts in this embodiment is based on the idea of dot-matrix positioning needle field, and consists of a guide rail base 1, a fixed clamping end assembly and a moving clamping end assembly.

[0024] The fixed clamping end assembly includes a fixed end slider 2, a fixed end cap 9, a fixed end body 12 and several positioning claws.

[0025] The slider at the fixed end cooperates with the base of the guide rail and can slide freely on the base of the guide rail. There are two threaded holes in the side wall of the fixed end slider, which are used to lock the fixed end slider to the rail base. There are 2 groups of screw holes on the upper surface of the fixed end slider, one group is connected with the fixed end cap 9, and the other group is connected with the fixed end body 12, so that it is connected with the fixed end slider 2 as a who...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com