Ceramic barber shears

A technology of hairdressing scissors and ceramic knives, applied in metal processing and other directions, can solve the problems of difficult and precise use, poor stability, strength, accuracy and design characteristics of connecting parts, and achieve beautiful shape, excellent connection accuracy, and connection. Stable, firm and not easy to loosen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

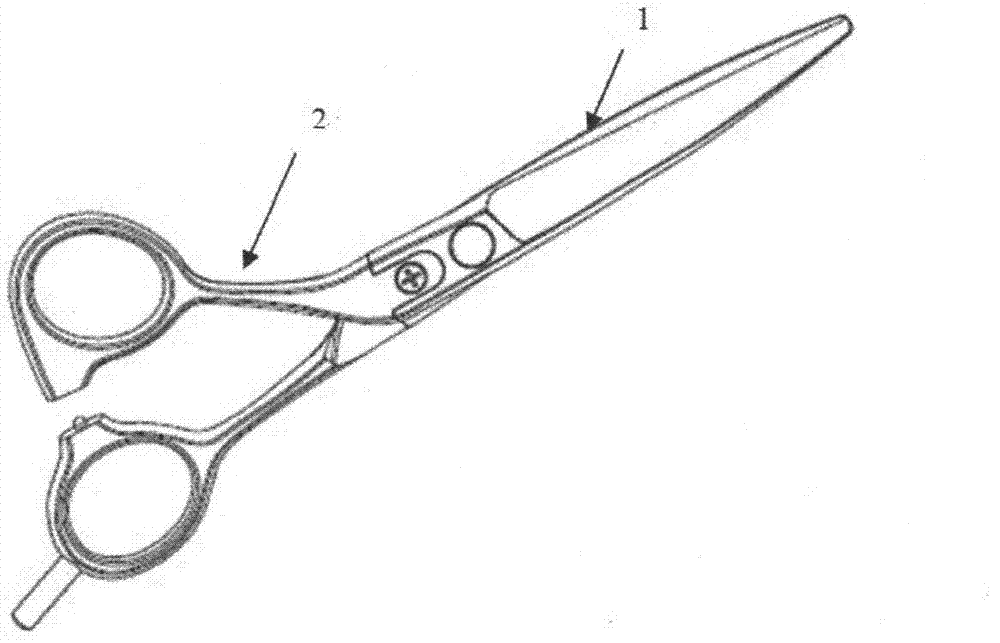

[0028] like figure 1 As shown, it is a structural schematic diagram of ceramic hair clippers. The ceramic hair clippers include a pair of flat hair clippers. 1 Made of zirconia ceramic, the metal handle is made of stainless steel.

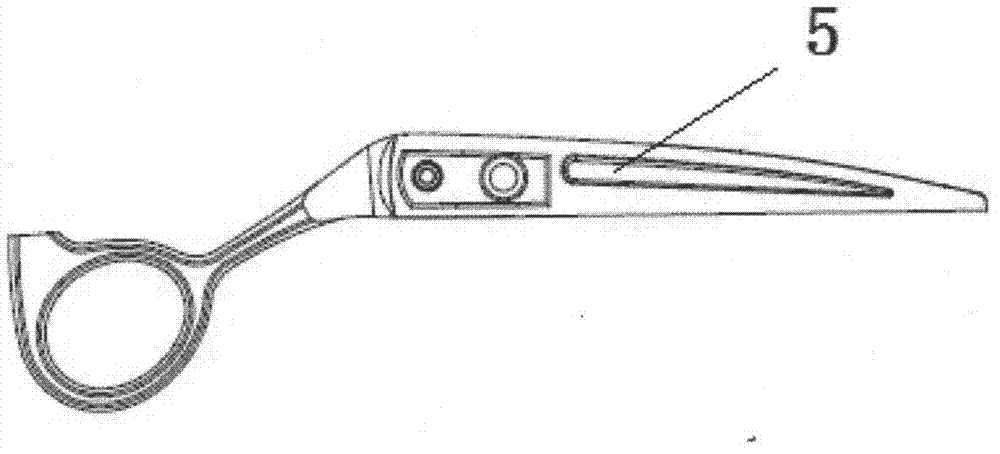

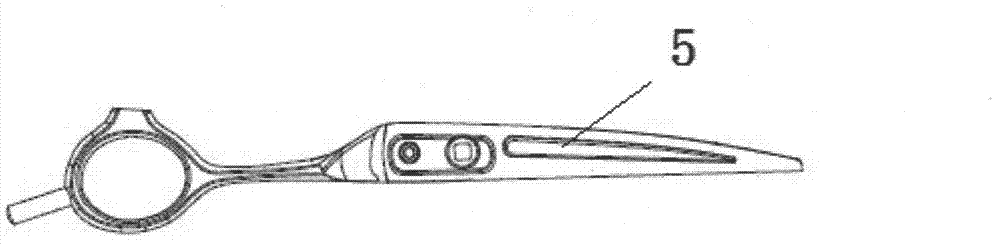

[0029] One end of the ceramic cutter head 1 has a concave part 7 for inserting the dovetail groove, which forms an opening plane in the base of the ceramic cutter head 1, and one end of the metal knife handle 2 has a convex part 8 for connecting the dovetail groove, and the convex part 8 for connecting the dovetail groove The convex portion 8 protrudes from the base of the metal handle 2, and the cross section of the insertion dovetail groove convex portion 8 and the insertion dovetail groove concave portion 7 is a dovetail shape, and the insertion dovetail groove convex portion 8 is inserted in the insertion dovetail groove concave portion 7, so that The socket dovetail concave portion 7 is provided with a positioning hole 14, and the socket dove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com