Wire falling array type inflatable unfolding wing

A technology of inflatable deployment and wings, applied in wings, aircraft parts, transportation and packaging, etc., can solve the problems of low connection efficiency, heavy weight, complex system, etc., and achieve the effect of high connection efficiency, light weight and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

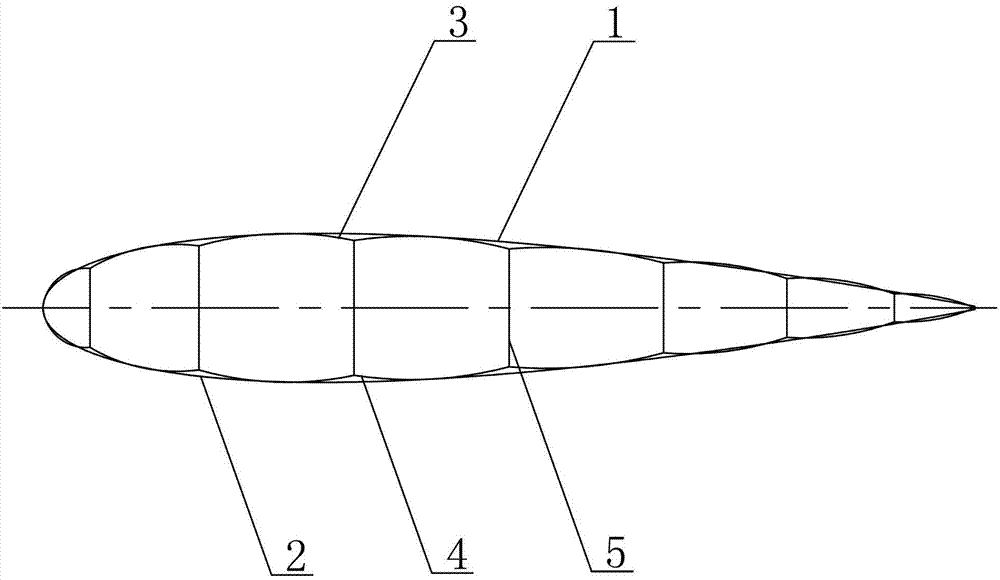

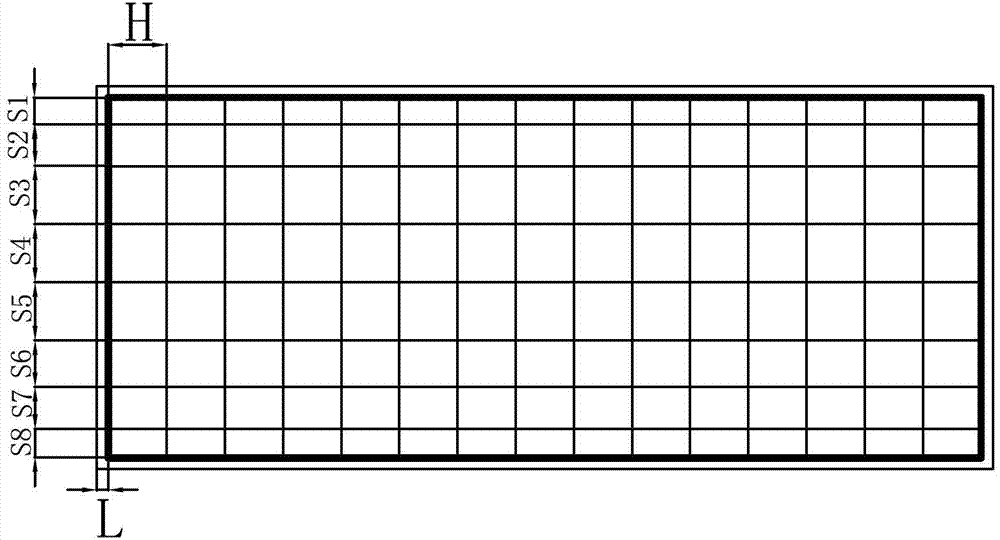

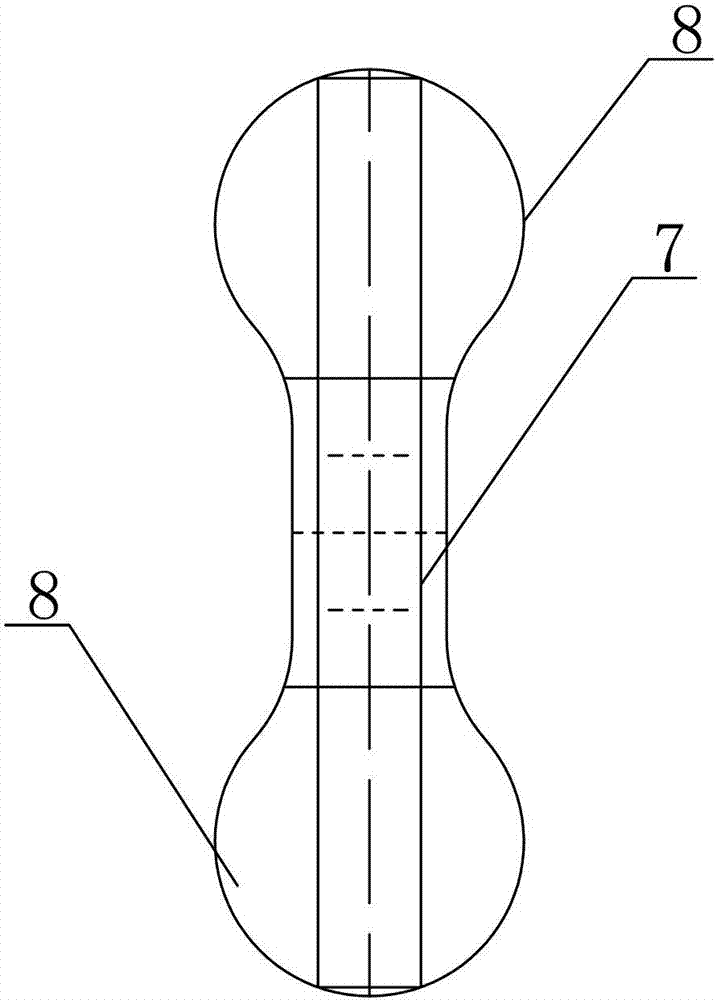

[0011] Specific implementation mode one: combine figure 1 Describe this embodiment, a doffing array type inflatable expandable wing of this embodiment includes an upper skin 1 of an inflatable wing and a lower skin 2 of an inflatable wing, an upper skin 1 of an air wing and a lower skin 2 of an inflatable wing The inflatable and expandable wings also include an upper connecting piece 3, a lower connecting piece 4 and a plurality of suspension locks 5, and the upper connecting piece 3 and the lower connecting piece 4 are respectively fixed by butt joint heat sealing. On the inner walls of the upper skin 1 of the airfoil and the lower skin 2 of the airfoil, a plurality of suspension locks 5 are vertically connected between the upper connecting piece 3 and the lower connecting piece 4 .

[0012] In this embodiment, a suspension cable structure is introduced into the cross section inside the inflatable wing, and the suspension cable and the upper and lower skins are connected thro...

specific Embodiment approach 2

[0015] Specific implementation mode two: combination figure 1 Describe this embodiment, the materials of the upper skin 1 and the upper connecting piece 3 of the inflated wing after butt joint heat sealing in this embodiment are PA, TIE, PE, TIE, PA, TIE and PE seven layers in total. Squeeze film. With such setting, the material has strong air barrier performance, good heat sealing performance, strong mechanical performance and anti-oxidation. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0016] Specific implementation mode three: combination figure 1 This embodiment will be described. The seven-layer co-extruded film of this embodiment has a thickness of 70 μm and a modulus of 550 MPa. Such setting facilitates single-sided heat sealing. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com