Tandem type triple-car dumper

A dumper and tandem technology, which is applied in the field of loading and unloading machinery, can solve the problems of reducing the span of the trailer beam, insufficient bearing capacity of the trailer beam and the supporting end plate, and excessive load of the trailer beam and the end plate, so as to reduce the foundation Excavation depth, good effect of synchronous operation, and effect of reducing the diameter of the end plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

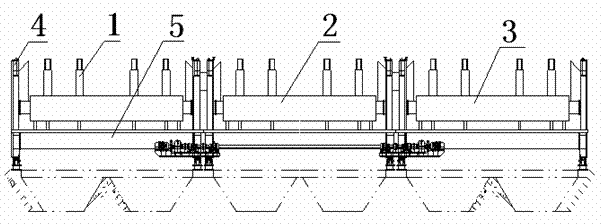

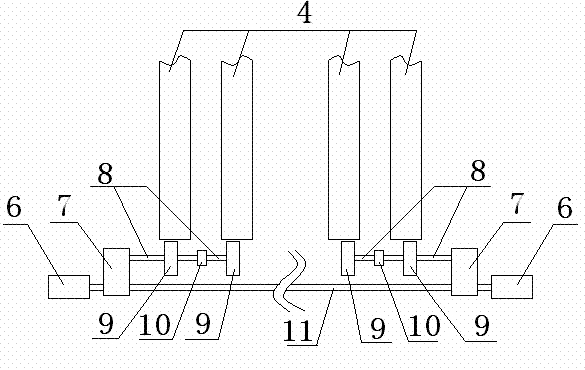

[0018] see figure 1 and figure 2 , The tandem three-car dumper provided by the present invention is composed of three single-car dumpers, that is, the first dumper 1, the second dumper 2 and the third dumper 3 are connected in sequence. Among them, a set of driving devices are respectively connected to the end plates 4 adjacent to the second dumper 2 on the first dumper 1 and the third dumper, and each set of driving devices includes a motor 6, a reducer 7, a drive shaft 8 and a drive gear 9. The two end plates 4 of the second dumper 2 are connected with drive shafts 8 and drive gears 9, and the two drive shafts 8 of the second dumper 2 are connected with the drive shafts 8 of the first dumper 1 and the third dumper 3 respectively. The second dumper 2 is connected with the first dumper 1 and the third dumper 3 through the two coup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com