BCTZ-based perovskite system multi-component lead-free piezoelectric ceramic and preparation method thereof

A lead-free piezoelectric and perovskite technology, which is applied in the field of ceramic compositions, can solve the problems of high pre-sintering sintering temperature, unstable sintering performance, and difficulty in densification during sintering, so as to achieve cost reduction, stable piezoelectric performance, and low Effect of sintering and pre-firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

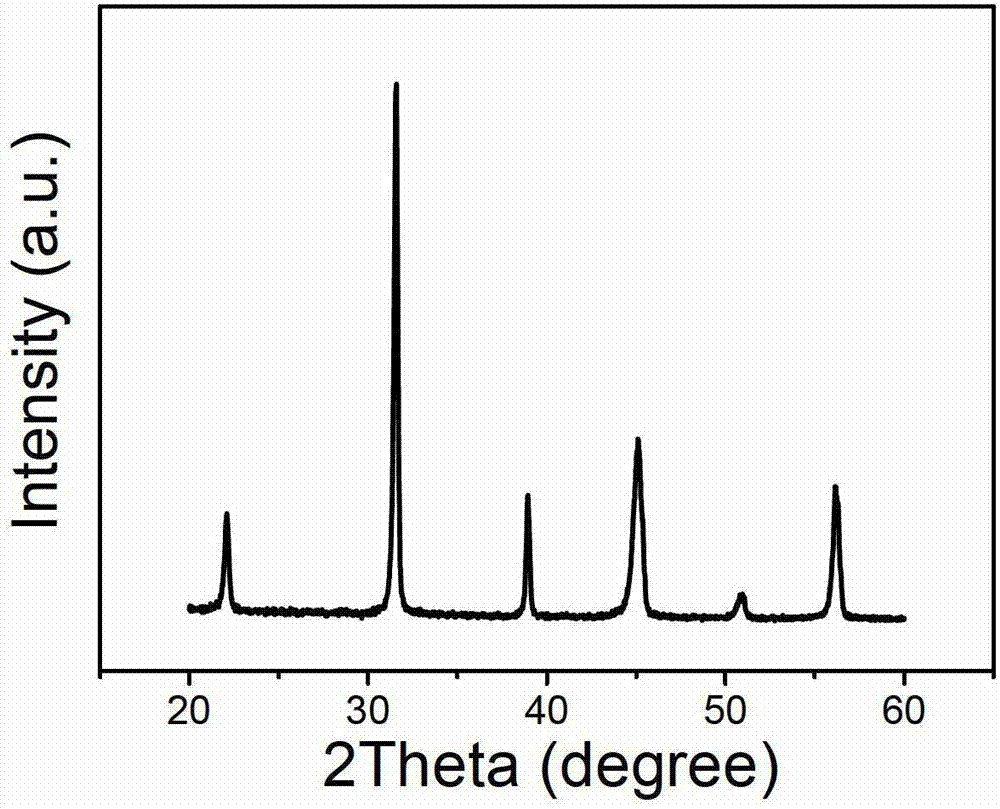

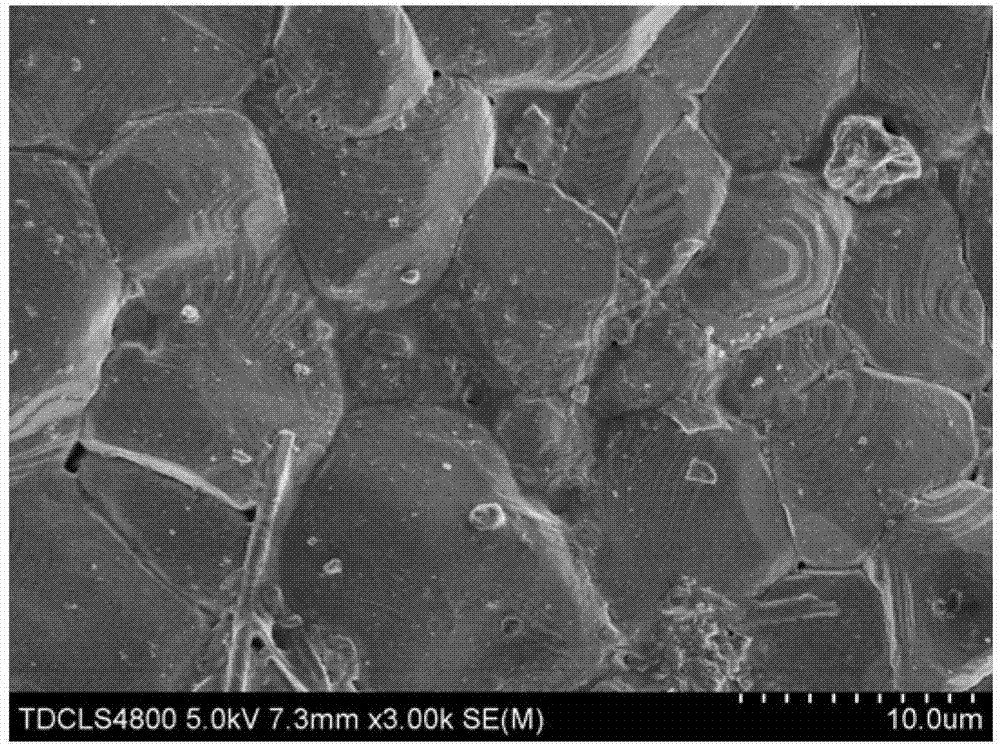

[0027] A kind of BCTZ based perovskite system multi-element lead-free piezoelectric ceramics of the present invention, its raw material component and its molar percentage are (1-y)[(1-x)Ba(Zr 0.2 Ti 0.8 )O 3 -x(Ca 0.7 Ca 0.3 )O 3 ]-y[(Na 0.52 K 0.44 Li 0.04 )(Nb 0.88 -Sb 0.08 Ta 0.04 )O], where x=0.40~0.50, y=0.001~0.05;

[0028] This embodiment can be divided into two components:

[0029] ①(Ba,Ca)(Ti,Zr)O 3 , referred to as BCTZ, namely (1-x)Ba(Zr 0.2 Ti 0.8 )O 3 -x(Ca 0.7 Ca 0.3 )O 3 , where x=0.48.

[0030] ② (Na 0.52 K 0.44 Li 0.04 )(Nb 0.88 Sb 0.08 Ta 0.04 )O 3 , referred to as KNNLST.

[0031] The preparation steps are as follows:

[0032] (1) with BaCO 3 , CaCO 3 , ZrO 2 ,TiO 2 The ingredients were weighed according to the stoichiometric ratio, and the prepared raw materials were ball-milled in anhydrous ethanol medium for 6 hours, dried at 100°C, kept for 2 hours, and then pre-fired at 1100°C, kept for 2 hours to obtain BCTZ powder.

[003...

Embodiment 2

[0054] The (Ba, Ca) (Ti, Zr) O of this embodiment 3 The (BCTZ) component is (1-x)Ba(Zr 0.2 Ti 0.8 )O 3 -x(Ca 0.7 Ca 0.3 )O 3 , where x=0.45. Another group is (Na 0.52 K 0.44 Li 0.04 )(Nb 0.88 Sb 0.08 Ta 0.04 )O 3 .

[0055] Analytical grade BaCO 3 , ZrO 2 ,TiO 2 and 98.0 CaCO 3 According to the stoichiometric ratio of BCTZ, the prepared materials were ball milled in anhydrous ethanol medium for 6 hours, dried at 100°C, kept for 2 hours, and then pre-fired at 1000°C, kept for 2 hours to obtain BCTZ powder. Use Li 2 CO 3 , K 2 CO 3 , Na 2 CO 3 , Nb 2 o 5 , Ta 2 o 5 and Sb 2 o 3 Batching is carried out according to the stoichiometric ratio of KNNLST, the prepared material is ball milled in anhydrous ethanol medium for 6 hours, dried at 100°C, kept for 2 hours, then pre-fired at 850°C, kept for 2 hours to obtain KNNLST powder. Weigh the BCTZ and KNNLST powders as (1-y)BCTZ-yKNNLST (y=0.05), ball mill them in absolute ethanol for 6 hours, dry them at 1...

Embodiment 3

[0060] The (Ba, Ca) (Ti, Zr) O of this embodiment 3 The (BCTZ) component is (1-x)Ba(Zr 0.2 Ti 0.8 )O 3 -x(Ca 0.7 Ca 0.3 )O 3 , where x=0.40. Another group is (Na 0.52 K 0.44 Li 0.04 )(Nb 0.88 Sb 0.08 Ta 0.04 )O 3 .

[0061] with BaCO 3 , CaCO 3 , ZrO 2 ,TiO 2 The batching was carried out according to the stoichiometric ratio of BCTZ, and the prepared material was ball-milled in anhydrous ethanol medium for 6 hours, dried at 100°C, kept for 2 hours, and then pre-fired at 1100°C, kept for 2 hours to obtain BCTZ powder. Use Li 2 CO 3 , K 2 CO 3 , Na 2 CO 3 , Nb 2 o 5 , Ta 2 o 5 and Sb 2 o 3 Batching is carried out according to the stoichiometric ratio of KNNLST, the prepared material is ball milled in anhydrous ethanol medium for 6 hours, dried at 100°C, kept for 2 hours, then pre-fired at 850°C, kept for 2 hours to obtain KNNLST powder. Weigh the BCTZ and KNNLST powders as (1-y)BCTZ-yKNNLST (y=0.015), ball mill them in absolute ethanol for 6 hours, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com